This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

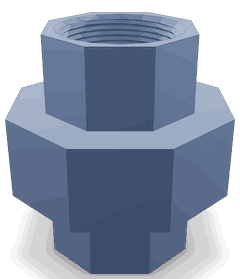

The Cummins 3395575 Plain Female Union is a component designed for use in heavy-duty truck systems. It serves a specific function within the fluid transfer systems of these vehicles, contributing to the overall efficiency and reliability of the truck’s operations. Understanding its purpose and significance is key to maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Plain Female Unions

A plain female union is a type of fitting used in fluid transfer systems to connect two pipes or hoses. It consists of a female-threaded end that screws onto a male-threaded component, providing a secure and leak-proof connection. These unions are widely used in various applications, including fuel, hydraulic, and coolant systems, due to their ability to facilitate easy assembly and disassembly without the need for additional tools 1.

Purpose of the Cummins 3395575 Plain Female Union

This Cummins part plays a role in the operation of a truck by connecting different components within the fluid transfer system. It facilitates the transfer of fluids such as fuel, coolant, or hydraulic fluid between parts of the system, ensuring a consistent and reliable flow. This connection is vital for the proper functioning of the truck’s engine and other systems that rely on fluid dynamics 2.

Key Features

The Cummins 3395575 Plain Female Union is characterized by several key features that enhance its performance and durability. It is typically made from high-quality materials such as brass or stainless steel, which offer excellent resistance to corrosion and wear. The design of the union includes precise threading and a robust construction to ensure a secure fit and long-lasting performance. Additionally, it may feature unique attributes such as a hex-shaped body for easy tightening and a smooth interior to minimize flow restriction 3.

Benefits

Using the Cummins 3395575 Plain Female Union offers several benefits. It contributes to improved system efficiency by providing a reliable connection that minimizes leaks and ensures consistent fluid flow. The union’s design also enhances the reliability of the fluid transfer system, reducing the likelihood of failures. Furthermore, its ease of installation and maintenance makes it a practical choice for both original equipment manufacturers and aftermarket applications 4.

Installation Process

Proper installation of the Cummins 3395575 Plain Female Union involves several steps to ensure a secure and leak-proof connection. Begin by ensuring the mating surfaces are clean and free of debris. Apply a compatible thread sealant to the male threads to enhance the seal. Carefully screw the female union onto the male component, using a wrench to tighten it to the manufacturer’s specified torque. Avoid over-tightening, as this can damage the threads or the union itself. Finally, inspect the connection for leaks before operating the system.

Common Issues and Troubleshooting

Common issues with the Cummins 3395575 Plain Female Union may include leaks, difficulty in tightening, or corrosion. To address leaks, ensure the threads are clean and properly sealed. If tightening is difficult, check for obstructions or misalignments. Corrosion can be mitigated by using unions made from corrosion-resistant materials and applying appropriate coatings or sealants. Regular inspection and maintenance can help identify and resolve these issues promptly.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3395575 Plain Female Union, routine maintenance is recommended. This includes regular inspection for signs of wear, corrosion, or leaks. Cleaning the union and its mating surfaces can prevent debris from affecting the connection. If any damage or significant wear is detected, replacement of the union may be necessary to maintain system integrity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industries. The company’s product offerings cater to various applications, from on-highway to off-highway and industrial uses, ensuring comprehensive coverage for diverse power needs.

Role of Part 3395575 Plain Female Union in Engine Systems

The Cummins 3395575 Plain Female Union is an essential component in the fluid dynamics of engine systems, particularly within the Module and Fuel Control subsystems.

In the Module subsystem, this union facilitates the secure connection between various fluid lines, ensuring a leak-free interface. Its design allows for easy disassembly and reassembly, which is beneficial during maintenance procedures. The union’s role here is to maintain consistent fluid pressure and flow, which is vital for the module’s operational efficiency.

Within the Fuel Control subsystem, the Plain Female Union plays a significant role in connecting fuel lines that deliver fuel from the tank to the engine. It ensures that the fuel system maintains integrity under varying pressure conditions, which is important for precise fuel delivery and engine performance. The union’s straightforward design reduces the risk of fuel leaks, contributing to the overall safety and reliability of the fuel control system.

Overall, the Cummins 3395575 Plain Female Union is integral to maintaining the fluid integrity and operational efficiency of both the Module and Fuel Control subsystems in engine systems.

Conclusion

The Cummins 3395575 Plain Female Union is a critical component in the fluid transfer systems of heavy-duty trucks. Its role in ensuring secure, leak-proof connections contributes significantly to the efficiency and reliability of these vehicles. Understanding its features, benefits, and proper installation and maintenance procedures is essential for optimizing the performance of heavy-duty trucks.

-

Diesel Mechanics, First Edition, Frank Sander, Global Media, 2007

↩ -

Handbook of Diesel Engines, Klaus Mollenhauer and Helmut Tschoeke, Springer, 2010

↩ -

Automotive Principles: Diagnosis and Service, James D. Halderman, Prentice Hall, 2012

↩ -

Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition, John Dixon, Cengage Learning, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.