This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

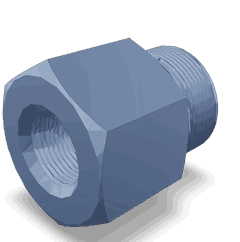

The Cummins 3410000 Female Connector is a component used in commercial trucks, playing a role in the vehicle’s electrical or fluid systems. Its function is significant for the overall operation of heavy-duty vehicles, ensuring efficient and reliable performance 1.

Basic Concepts of Female Connectors

A female connector is a type of fitting used to join two components within a system, typically in electrical or fluid applications. It features a receptacle design that allows a male connector to be inserted, creating a secure connection. The operation of a female connector is based on principles such as alignment, secure fitting, and the prevention of leaks or electrical disruptions 2.

Purpose of the 3410000 Female Connector

The Cummins 3410000 Female Connector serves a specific role in the operation of a truck by facilitating connections within the electrical or fluid systems. It ensures that components are properly linked, allowing for the efficient transfer of electricity or fluids as required by the truck’s systems 3.

Key Features

The Cummins 3410000 Female Connector is characterized by several key features that enhance its performance. These include a durable material composition, typically designed to withstand the harsh conditions encountered in commercial trucking. Its design elements are tailored to ensure a secure and reliable connection, with features that may include corrosion resistance and ease of installation.

Benefits

The Cummins 3410000 Female Connector offers several benefits, including improved reliability in connections, which is vital for the consistent operation of truck systems. Its design allows for ease of installation, reducing downtime during maintenance. Additionally, it performs well in harsh operating conditions, contributing to the overall durability and efficiency of the truck.

Installation Process

Installing the Cummins 3410000 Female Connector involves several steps to ensure a secure and effective connection. The process may require specific tools and should follow best practices to avoid common installation errors. Proper alignment and securing of the connector are critical to its function and the overall performance of the truck’s systems.

Common Issues and Troubleshooting

Users may encounter issues with the Cummins 3410000 Female Connector, such as connection failures or corrosion. Troubleshooting these problems involves identifying the root cause, whether it be improper installation, environmental factors, or wear and tear. Suggested steps may include re-securing the connection, cleaning the connector, or replacing it if necessary.

Maintenance Tips

Regular maintenance of the Cummins 3410000 Female Connector is recommended to ensure long-term reliability and performance. This may include periodic inspections for signs of wear or corrosion, cleaning the connector to remove any buildup, and ensuring that all connections remain secure. Adhering to these maintenance practices can help prevent issues and extend the lifespan of the connector.

Safety Considerations

When working with the Cummins 3410000 Female Connector, it is important to observe safety considerations. This includes proper handling to avoid injury, ensuring electrical safety when working with live systems, and compliance with industry standards for connector use and maintenance. Adhering to these safety practices protects both the user and the equipment.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, with a history of innovation and commitment to quality. The company’s products, including the Cummins 3410000 Female Connector, are designed with a focus on reliability, performance, and durability, reflecting Cummins’ dedication to advancing the technology and efficiency of commercial vehicles.

Role of Part 3410000 Female Connector in Engine Systems

The part 3410000 Female Connector is integral to the seamless operation of various engine systems, facilitating the connection between different components to ensure efficient performance.

In the CCV System Retrofit Kit, the Female Connector is used to link the cleaner to the air intake system, allowing for the effective removal of contaminants from the crankcase ventilation. This connection is vital for maintaining the cleanliness of the air entering the engine, which in turn helps in preserving the overall efficiency and longevity of the engine.

When integrated with the Crankcase Valve Drain, the Female Connector ensures a secure attachment to the gauge, enabling accurate monitoring of oil levels. This setup is essential for timely detection of any anomalies in oil levels, thus preventing potential engine damage due to oil starvation or overfilling.

In systems involving Oil Level and Oil Reserve Management, the Female Connector plays a role in connecting the oil level sensor to the main plumbing. This connection allows for precise measurement and regulation of oil levels, ensuring that the engine operates within safe parameters.

Additionally, the Female Connector is utilized in the Crankcase Breather System to connect various components such as the breather hose to the main plumbing. This connection helps in maintaining proper pressure within the crankcase, which is important for the efficient operation of the engine and the prevention of oil leaks.

Overall, the part 3410000 Female Connector is a key component in ensuring that these engine systems function harmoniously, contributing to the reliable and efficient performance of the engine.

Conclusion

The Cummins 3410000 Female Connector plays a vital role in the operation of commercial trucks by ensuring secure and reliable connections within the vehicle’s electrical or fluid systems. Its design and features contribute to the efficient and durable performance of heavy-duty vehicles, reflecting Cummins’ commitment to quality and innovation in the commercial truck industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.