This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

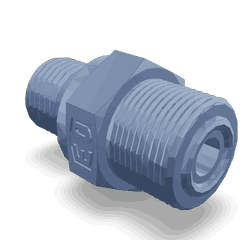

The Cummins Male Connector Part #3420667 is a specialized component designed for use in commercial truck operations. This part is integral to the efficient functioning of various systems within trucks, ensuring reliable performance and durability. Understanding its purpose and significance can enhance the maintenance and operational efficiency of commercial vehicles.

Basic Concepts of Male Connectors

Male connectors are components used to join two parts of a system together, typically in electrical or fluid systems. They feature a protruding pin or plug that fits into a corresponding female connector, creating a secure and often sealed connection. In automotive and industrial settings, male connectors are vital for transmitting power, signals, or fluids between different parts of a system, ensuring seamless operation and integration 1.

Purpose of the Cummins Male Connector Part #3420667

The Cummins Male Connector Part #3420667 serves a specific role within the electrical or fluid systems of a truck. It facilitates the connection between various components, allowing for the transfer of power or fluids as required. This part ensures that the connections are secure, reducing the risk of leaks or electrical faults, which can be critical for the safe and efficient operation of the vehicle 2.

Key Features

This Cummins part is characterized by several key features that enhance its performance and durability. Its design includes a robust construction that can withstand the rigors of commercial truck operations. The material composition is chosen for its resistance to corrosion and wear, ensuring long-lasting use. Additionally, the connector may feature unique attributes such as sealed connections to prevent fluid or electrical leakage, and easy-to-use locking mechanisms for secure attachment.

Benefits

Using the Male Connector offers several advantages. It contributes to improved system efficiency by ensuring reliable connections that minimize the risk of interruptions or failures. The design of the connector also enhances the reliability of the truck’s systems, reducing the likelihood of maintenance issues. Furthermore, the part is designed for ease of installation or replacement, allowing for quick and straightforward maintenance procedures.

Installation and Usage

Proper installation of the Male Connector involves several steps to ensure a secure and effective connection. Begin by identifying the correct location for the connector within the truck’s system. Clean the area to remove any debris or contaminants that could affect the connection. Align the male connector with the corresponding female connector and press firmly to ensure a secure fit. Verify the connection by checking for any signs of leakage or looseness. Follow any specific guidelines provided by the manufacturer for best practices and safety considerations during installation.

Maintenance and Care

To ensure the longevity and optimal performance of the Male Connector, regular maintenance is recommended. This includes periodic cleaning of the connector to remove any buildup of dirt or grime that could affect its function. Inspect the connector for signs of wear or damage, and replace it if necessary to prevent potential system failures. Following the manufacturer’s guidelines for maintenance will help maintain the integrity of the connection and the overall system.

Troubleshooting Common Issues

Male connectors, including the Cummins Male Connector Part #3420667, may encounter common issues such as loose connections, corrosion, or fluid leaks. To address these problems, first, ensure that the connector is properly aligned and securely attached. If corrosion is present, clean the affected areas and consider applying a protective coating. For fluid leaks, check the seals and connections for any damage and replace them if necessary. Preventive measures include regular inspections and maintenance to identify and address potential issues before they become significant problems.

Compatibility and Applications

The Male Connector is designed for use in specific types of trucks and systems. It is compatible with a range of Cummins engines and is often used in applications where reliable electrical or fluid connections are required. Notable use cases include connections in fuel systems, electrical harnesses, and other critical systems within commercial trucks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck and engine industry. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance the performance and efficiency of commercial vehicles.

Compatibility of Male Connector Part 3420667 with Cummins Engines

The Male Connector part 3420667, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is crucial for ensuring proper fluid flow and connection integrity within the engine system. Below is a detailed overview of its compatibility with the specified engine models.

QSV81G and QSV91G Engines

The Male Connector part 3420667 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The connector ensures that the fluid pathways remain secure and efficient, contributing to the overall operational efficiency of these engines.

QSW/QSV82 Engines

For the QSW/QSV82 engines, the Male Connector part 3420667 is engineered to fit perfectly, ensuring that the fluid connections are airtight and durable. This compatibility is essential for maintaining the performance standards expected from these engines, particularly in demanding environments.

QSW27 and QSW36 Engines

The engines QSW27 and QSW36 also benefit from the use of the Male Connector part 3420667. This part is designed to integrate smoothly with these models, providing a reliable connection that supports the engine’s operational needs. The precision fit ensures that there are no leaks or inefficiencies in the fluid pathways.

QSW73 Engines

Lastly, the QSW73 engines are also compatible with the Male Connector part 3420667. This compatibility ensures that the engines can operate at peak efficiency, with the connector playing a key role in maintaining the integrity of the fluid connections. The design of the connector is such that it fits snugly, preventing any potential issues that could arise from loose or improper connections.

Each of these engines relies on the Male Connector part 3420667 to maintain optimal performance and reliability. The compatibility of this part with the listed engines underscores its importance in ensuring that the engines function smoothly and efficiently.

Role of Part 3420667 Male Connector in Engine Systems

The Part 3420667 Male Connector is integral to the seamless operation of various engine systems. It facilitates the connection between different components, ensuring efficient fluid transfer and mechanical interaction.

Fuel System Integration

In the fuel assembly plumbing, the Male Connector ensures a secure link between the fuel drain assembly tube and other fuel lines. This connection is vital for maintaining fuel pressure and preventing leaks, which are essential for consistent engine performance. Additionally, it plays a role in the fuel plumbing by connecting to the plumbing fuel assembly, enhancing the overall reliability of the fuel delivery system.

Oil System Functionality

Within the oil assembly plumbing, the Male Connector is used to join the oil fill assembly arrangement with other oil passages. This ensures that oil is distributed evenly throughout the engine, lubricating moving parts and reducing wear. The connector’s robust design helps maintain oil pressure, which is necessary for the proper functioning of engine components.

Mechanical Linkages

The Male Connector also supports mechanical components such as the rocker assembly lever and the lever connected to the rocker. By providing a stable connection point, it ensures that the motion from the cam is accurately transferred to the follower and subsequently to the cam assembly follower. This precise transmission of motion is essential for the timing and efficiency of the engine’s valve operation.

Cylinder Head and Valve Train

In the context of the cylinder head conversion kit, the Male Connector may be used in the housing valve tappet mounting. This application ensures that the valve tappets are securely mounted and can operate efficiently. The connector aids in maintaining the integrity of the valve train, which is fundamental for the engine’s combustion process.

Overall System Reliability

By integrating with these various components, the Part 3420667 Male Connector enhances the overall reliability and performance of the engine systems. Its role in ensuring secure and efficient connections between critical parts cannot be overstated, making it a key element in the engine’s design and function.

Conclusion

The Cummins Male Connector Part #3420667 is a critical component in the operation of commercial trucks, ensuring reliable and efficient connections within various systems. Its robust design, compatibility with a range of Cummins engines, and key role in engine systems make it an essential part for maintaining the performance and durability of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.