This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

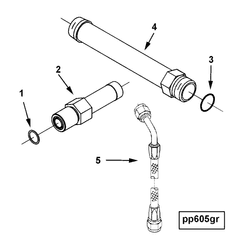

The Cummins 3631970 Male Connector is a specialized component designed for use in commercial trucks. It plays a role in ensuring the proper operation of various systems within these vehicles. Understanding its function and significance can help fleet operators and technicians maintain and optimize truck performance.

Basic Concepts of Male Connectors

Male connectors are components used to join two parts of a system together, typically in electrical or fluid systems. They feature a protruding pin or plug that fits into a corresponding female connector. In automotive and industrial applications, male connectors facilitate the transfer of electricity, fluids, or data between components, ensuring seamless operation and communication within the system 1.

Purpose of the 3631970 Male Connector

The 3631970 Male Connector is specifically designed to play a role in the electrical or fluid systems of commercial trucks. It ensures a secure and reliable connection between components, which is crucial for the efficient operation of the truck. This connector helps in transmitting electrical signals or fluids with minimal loss or interference, contributing to the overall functionality of the truck’s systems 2.

Key Features

The 3631970 Male Connector is constructed from high-quality materials, ensuring durability and resistance to wear and corrosion. Its design includes precise engineering to provide a snug fit within the corresponding female connector, enhancing the stability and reliability of the connection. Additionally, it may feature protective coatings or seals to further improve its performance in harsh environments.

Benefits

The use of the 3631970 Male Connector offers several advantages. It contributes to improved system efficiency by ensuring a stable and secure connection. This reliability reduces the likelihood of system failures and enhances the overall performance of the truck. Additionally, its durable construction can lead to cost savings for fleet operators by reducing the need for frequent replacements or repairs.

Installation Process

Installing the 3631970 Male Connector requires careful attention to detail to ensure a secure and effective connection. The process involves aligning the connector with the corresponding female port, inserting it firmly, and verifying that it is properly seated. Tools such as wrenches or specialized connectors may be required. Following manufacturer guidelines and best practices will help achieve a reliable connection.

Troubleshooting Common Issues

Common issues with male connectors include loose connections and corrosion. To address these problems, inspect the connector for signs of wear or damage. Cleaning the connector and its mating surface can help remove corrosion and debris. If the connector is loose, re-seating it or replacing it may be necessary to restore a secure connection.

Maintenance Tips

Regular maintenance of the 3631970 Male Connector is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear, corrosion, or damage. Cleaning the connector and its mating surfaces can prevent buildup that may interfere with the connection. Following the manufacturer’s guidelines for maintenance will help maintain the connector’s effectiveness.

Compatibility and Applications

The 3631970 Male Connector is designed for use in specific types of trucks and systems. It is commonly applied in scenarios where reliable electrical or fluid connections are required. Understanding its compatibility with various truck models and systems is important for ensuring proper installation and function.

Safety Considerations

When working with the 3631970 Male Connector, it is important to observe safety practices and precautions. This includes ensuring that the truck’s electrical system is de-energized before beginning any work to prevent electrical shock. Proper handling procedures should be followed to avoid damage to the connector or injury to the technician.

About Cummins

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. With a rich history of innovation and a broad product range, Cummins has established a strong reputation for reliability and performance in the automotive and industrial sectors 3.

Male Connector 3631970 Compatibility with Cummins Engines

The Male Connector part number 3631970, manufactured by Cummins, is designed to ensure seamless integration and functionality within various Cummins engine models. This part is engineered to fit precisely with the K38 and K50 engine series, providing a reliable connection that is essential for the engine’s operation.

K38 Engine Series

In the K38 engine series, the Male Connector 3631970 is integral to the engine’s fuel system. It ensures that fuel lines are securely attached, preventing leaks and maintaining the engine’s efficiency. The connector’s design allows for easy installation and removal, facilitating maintenance and repairs. Its robust construction ensures durability, even under the demanding conditions of engine operation.

K50 Engine Series

Similarly, in the K50 engine series, the Male Connector 3631970 plays a pivotal role in the engine’s hydraulic and fuel systems. This part is designed to withstand high pressure and temperature, making it suitable for the rigorous demands of the K50 engines. Its precision-engineered fit guarantees that connections are tight and secure, which is crucial for the engine’s performance and longevity.

Grouping of Engines

The Male Connector 3631970 is particularly well-suited for the K38 and K50 engines due to their shared design principles and operational requirements. Both engine series benefit from the connector’s ability to provide a leak-proof and secure connection, which is vital for maintaining engine efficiency and reliability. The connector’s compatibility with these engines underscores Cummins’ commitment to quality and performance in their engine components.

Role of Part 3631970 Male Connector in Engine Systems

The part 3631970 Male Connector is an integral component in various engine systems, facilitating the secure and efficient transfer of fluids and gases. In the context of plumbing systems within engines, this connector ensures a reliable seal between different sections of the plumbing network, minimizing the risk of leaks and maintaining system integrity.

When integrated with injectors, the Male Connector plays a significant role in delivering precise amounts of fuel to the combustion chamber. Its design allows for a consistent and controlled flow of fuel, which is essential for optimal engine performance and efficiency.

In the step oil supply fitting, the Male Connector is responsible for connecting the oil supply lines to the engine’s lubrication system. This ensures that the moving parts within the engine receive a continuous and adequate supply of oil, reducing friction and wear, and enhancing the longevity of the engine components.

Overall, the part 3631970 Male Connector is a key element in maintaining the functionality and efficiency of these engine systems, ensuring that fluids and gases are delivered where needed with minimal loss or contamination.

Conclusion

The Cummins 3631970 Male Connector is a critical component in the operation of commercial trucks and Cummins engines. Its role in ensuring secure and reliable connections within electrical and fluid systems contributes to the overall efficiency and performance of these vehicles. Proper installation, maintenance, and understanding of its compatibility with specific engine models are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.