This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

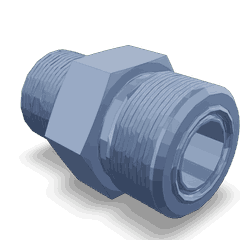

The Cummins 3640382 Male Connector is a specialized component designed for use in commercial truck systems. It serves a significant role in ensuring the proper functioning of various truck systems by facilitating secure and reliable connections. Understanding its purpose and significance is vital for maintaining the efficiency and reliability of commercial trucks.

Basic Concepts of Male Connectors

Male connectors are components used to establish connections between different parts of a system. They typically feature protruding pins or terminals that fit into corresponding female connectors. In automotive and industrial settings, male connectors are employed in electrical, hydraulic, and pneumatic systems to ensure secure and efficient transmission of power, signals, or fluids. Their design allows for easy assembly and disassembly, making them ideal for applications where frequent connections and disconnections are necessary 1.

Purpose of the Cummins 3640382 Male Connector

The Cummins 3640382 Male Connector plays a specific role in the operation of a truck by providing a secure connection within the truck’s electrical or fluid systems. It is designed to interface with corresponding female connectors, ensuring a stable and reliable connection that is crucial for the proper functioning of the system. This connector is often used in applications where durability and reliability are paramount, such as in the harsh environments typical of commercial trucking 2.

Key Features

The Cummins 3640382 Male Connector is characterized by several key features that enhance its performance and durability. Its design includes robust materials that withstand the rigors of commercial truck operations. The connector is engineered to provide a tight and secure fit, minimizing the risk of disconnection or failure. Additionally, it may feature corrosion-resistant coatings and specialized terminals that ensure reliable electrical or fluid transmission 3.

Benefits

The Cummins 3640382 Male Connector offers several advantages. It provides improved connectivity, ensuring that electrical or fluid systems operate efficiently. Its durable construction enhances reliability, reducing the likelihood of failures in harsh operating conditions. The connector is also designed for ease of installation, allowing for quick and straightforward setup. Furthermore, its robust design contributes to the longevity of the connection, minimizing maintenance requirements.

Installation and Usage

Proper installation of the Cummins 3640382 Male Connector is crucial for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines to ensure a secure and reliable connection. This may involve cleaning the connection points, ensuring proper alignment, and applying any necessary torque specifications. Careful attention to these procedures will help prevent issues such as poor connectivity or increased wear.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for ensuring the longevity and optimal performance of the Cummins 3640382 Male Connector. Common issues may include corrosion, wear, or poor connections. Inspecting the connector for signs of damage or corrosion and cleaning it as necessary can help prevent these problems. If issues arise, such as intermittent connections or failure to connect, it may be necessary to replace the connector to restore proper function.

Safety Considerations

When working with the Cummins 3640382 Male Connector, it is important to observe several safety considerations. Ensure that the truck’s power is disconnected before beginning any installation or maintenance procedures to prevent electrical shocks or accidents. Use appropriate personal protective equipment (PPE) when handling the connector to protect against injuries. Follow all manufacturer guidelines and safety protocols to ensure a safe working environment.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. Founded in 1919, Cummins has a long history of innovation and excellence. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, designed to meet the demanding needs of commercial trucking. Cummins is renowned for its commitment to quality, reliability, and customer satisfaction, making it a trusted name in the industry.

Compatibility of Male Connector Part 3640382 with Cummins Engines

The Male Connector part number 3640382, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is integral for ensuring proper fluid flow and system integrity within the engine’s hydraulic or fuel systems.

QSK50 Series

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

The Male Connector part 3640382 is compatible with the QSK50 series engines, specifically the CM2150 MCRS and CM2350 K108 variants. This compatibility ensures that the connector can be used across these models without any modifications, providing a standardized solution for maintaining and repairing these engines.

In these engines, the Male Connector part 3640382 is often used in the hydraulic system, where it connects various hydraulic lines and components. Its robust design and precise fit are crucial for maintaining the system’s efficiency and reliability. The connector’s material and construction are specifically engineered to withstand the high pressures and temperatures typical of engine hydraulic systems.

By using the Male Connector part 3640382, technicians and engineers can ensure that their QSK50 series engines operate smoothly, with minimal risk of leaks or failures in the hydraulic connections. This part’s compatibility across the CM2150 MCRS and CM2350 K108 models highlights its versatility and importance in maintaining the integrity of these engines.

Role of Part 3640382 Male Connector in Engine Systems

The 3640382 Male Connector is integral to the seamless operation of several engine components, facilitating efficient and reliable performance.

Drive System Integration

In the drive system, the 3640382 Male Connector ensures a secure and consistent electrical connection between the control module and the drive motor. This connection is essential for transmitting signals that regulate the motor’s speed and torque, directly influencing the vehicle’s acceleration and overall driving dynamics. The Male Connector’s robust design withstands the vibrations and heat generated during operation, maintaining signal integrity and preventing intermittent failures.

Fan Control System

Within the fan control system, the 3640382 Male Connector plays a significant role in managing the electrical interface between the fan motor and the engine’s thermal management system. It allows for precise control over the fan’s operation, ensuring that it activates only when necessary to maintain optimal engine temperature. This not only enhances engine efficiency but also contributes to reduced wear and tear on the fan motor by preventing unnecessary operation.

Oil Manifold System

In the oil manifold system, the 3640382 Male Connector is responsible for establishing a reliable electrical link between the oil pressure sensors and the engine control unit (ECU). Accurate oil pressure readings are vital for the ECU to make real-time adjustments to the engine’s performance, ensuring that lubrication is adequate under varying operating conditions. The Male Connector’s precise fit and secure connection help in delivering consistent and accurate data, which is fundamental for the ECU’s decision-making process regarding oil flow and pressure management.

Conclusion

The Cummins 3640382 Male Connector is a critical component in the operation and maintenance of commercial truck systems. Its robust design, compatibility with various Cummins engine models, and role in ensuring secure and reliable connections make it indispensable for maintaining the efficiency and reliability of these vehicles. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the performance and longevity of this Cummins part.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.