This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

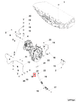

The Cummins 3697187 Female Connector is a specialized component designed for use in commercial truck operations. This connector plays a role in facilitating secure and reliable connections within the truck’s electrical or fluid systems. Its significance lies in ensuring the efficient and safe operation of various truck systems, contributing to overall vehicle performance and reliability 1.

Basic Concepts of Female Connectors

A female connector is a type of fitting used in electrical or fluid systems to create a secure connection between two components. It typically features a receptacle that allows a male connector to be inserted, forming a tight seal. In automotive and industrial settings, female connectors are used to join wires, hoses, or other components, ensuring the proper flow of electricity or fluids and maintaining system integrity 2.

Purpose of the 3697187 Female Connector

The Cummins 3697187 Female Connector serves a specific function within a truck’s electrical or fluid systems. It is designed to provide a secure connection point for various components, ensuring that electrical signals or fluids are transmitted efficiently and without interruption. This connector is integral to maintaining the functionality of the truck’s systems, contributing to its overall performance and reliability 3.

Key Features

The Cummins 3697187 Female Connector is characterized by several key features that enhance its performance and durability. These include a robust material composition, typically made from high-quality plastics or metals, ensuring resistance to wear and environmental factors. The design elements of the connector, such as its precise fit and secure locking mechanism, contribute to its reliability. Additionally, any unique characteristics, such as corrosion-resistant coatings or enhanced sealing capabilities, further improve its functionality 4.

Benefits

The Cummins 3697187 Female Connector offers several benefits that contribute to improved system reliability and ease of use. These include a secure and stable connection that reduces the risk of disconnections or leaks, simplifying the installation process with its design that allows for quick and easy attachment. Maintenance advantages are also provided, as the connector is built to withstand harsh conditions, reducing the need for frequent replacements or repairs 5.

Installation Process

Proper installation of the Cummins 3697187 Female Connector involves several steps to ensure a secure and effective connection. Begin by identifying the correct location for the connector within the truck’s system. Use the appropriate tools, such as a torque wrench, to ensure the connector is tightened to the manufacturer’s specifications. Follow best practices, such as ensuring the mating surfaces are clean and free of debris, to achieve a tight seal. Verify the connection by testing for proper function and integrity 6.

Troubleshooting Common Issues

Common problems that may arise with the Cummins 3697187 Female Connector include connection failures or corrosion. To address these issues, first, inspect the connector for signs of damage or wear. Clean the connector and mating surfaces to remove any corrosion or debris. If the connector is damaged, replace it with a new one, ensuring a proper fit and secure connection. Regular inspections and maintenance can help prevent these issues from occurring 7.

Maintenance Tips

To prolong the lifespan of the Cummins 3697187 Female Connector, regular maintenance practices are recommended. This includes routine inspections to check for signs of wear, corrosion, or damage. Cleaning the connector and mating surfaces can prevent buildup that may affect performance. Additionally, ensuring that the connector is properly tightened and secured can help maintain a reliable connection. Following these maintenance tips can contribute to the overall durability and functionality of the connector 8.

Safety Considerations

When working with the Cummins 3697187 Female Connector, it is important to observe safety practices and precautions. This includes ensuring that the electrical system is de-energized before beginning any work to prevent electrical shock. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Additionally, follow manufacturer guidelines for installation and maintenance to ensure system integrity and safety 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance products. The company’s extensive product range and commitment to innovation contribute to its standing as a trusted provider of power solutions 10.

Compatibility with Engine Models

The Cummins Female Connector 3697187 is a versatile component designed to fit seamlessly with a range of Cummins engine models. This part is engineered to ensure reliable connections and compatibility across various engine configurations. Below is a detailed overview of its compatibility with specific engine models:

15N CM2380 M104B

The 15N CM2380 M104B engine benefits from the 3697187 Female Connector, which provides a secure and efficient connection point. This compatibility ensures that the engine’s operational integrity is maintained, facilitating smooth performance and reliability.

ISG12 CM2880 G107 and KTA19GC CM558

Both the ISG12 CM2880 G107 and KTA19GC CM558 engines are designed to integrate the 3697187 Female Connector. This part is crucial for maintaining the structural integrity and operational efficiency of these engines, ensuring that all connections are robust and reliable.

QSG12/X12 CM2350 G110, X11 CM2670 X126B, X12 CM2670 X121B, X13 CM2670 X122B, and Z14 CM2670 Z103B

The 3697187 Female Connector is also compatible with the QSG12/X12 CM2350 G110, X11 CM2670 X126B, X12 CM2670 X121B, X13 CM2670 X122B, and Z14 CM2670 Z103B engines. This compatibility ensures that these engines can maintain their operational efficiency and reliability, with the connector providing a secure and dependable connection point.

The Cummins Female Connector 3697187 is a critical component for ensuring the seamless integration and reliable performance of these engine models. Its compatibility across a range of engine types underscores its versatility and importance in maintaining engine functionality 11.

Role of Part 3697187 Female Connector in Engine Systems

The part 3697187 Female Connector is integral to the seamless operation of various engine systems. In the context of the module, this connector facilitates the secure attachment of wiring harnesses, ensuring reliable data transmission between the module and other electronic components. This is essential for the module’s ability to monitor and adjust engine performance parameters in real-time.

Within the engine control system, the Female Connector plays a significant role by linking sensors and actuators to the engine control unit (ECU). This connection allows for the accurate collection of data such as temperature, pressure, and airflow, which the ECU uses to make precise adjustments to fuel injection, ignition timing, and other critical functions.

In plumbing applications, the Female Connector is used to join fluid lines, whether they carry fuel, coolant, or hydraulic fluid. Its robust design ensures a leak-free seal, which is vital for maintaining system integrity and efficiency. Proper fluid management is key to preventing engine overheating and ensuring consistent performance.

Lastly, in turbocharger systems, the Female Connector is employed to link the turbocharger’s electronic control unit with the main engine control system. This integration allows for optimized turbocharger operation, enhancing engine responsiveness and power output while maintaining safe operating parameters. The connector ensures that the turbocharger receives the necessary signals to adjust boost levels according to driving conditions and engine load 12.

Conclusion

The Cummins 3697187 Female Connector is a vital component in the operation of commercial truck engines, ensuring secure and reliable connections within electrical and fluid systems. Its robust design, compatibility with various engine models, and role in maintaining system integrity make it an essential part for ensuring the efficient and safe operation of truck systems. Regular maintenance and proper installation are key to maximizing the lifespan and performance of this connector.

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Service Manual (5613077).

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Cummins Inc. (n.d.). Service Manual (5613077).

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Service Manual (5613077).

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Service Manual (5613077).

↩ -

Cummins Inc. (n.d.). Service Manual (5613077).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.