This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

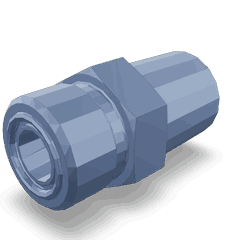

The Cummins Male Connector 3698416 is a specialized component designed for use in commercial truck operations. It plays a role in ensuring the efficient and reliable operation of various systems within these vehicles. Understanding its purpose and significance can help maintain the overall performance and longevity of commercial trucks.

Basic Concepts of Male Connectors

Male connectors are components used to join two parts of a system together, typically by fitting into a corresponding female connector. They are integral in both automotive and industrial applications, facilitating the transfer of fluids, gases, or electrical signals. Their design ensures a secure connection, minimizing the risk of leaks or disconnections, which is important for the safe and efficient operation of machinery 1.

Purpose of the Cummins Male Connector 3698416

The Cummins Male Connector 3698416 is specifically engineered to play a role in the electrical or fluid systems of a truck. It ensures a secure and reliable connection, which is important for the consistent operation of these systems. By providing a stable link between components, it helps maintain the integrity of the system, ensuring that fluids or electrical signals are transmitted efficiently.

Key Features

The Cummins Male Connector 3698416 is characterized by several design elements and materials that enhance its performance and durability. It is constructed from high-quality materials to withstand the rigors of commercial truck operations. Its design includes features that ensure a tight and secure fit, reducing the likelihood of disconnections or leaks. Additionally, it may incorporate elements that protect against corrosion and wear, further enhancing its longevity 2.

Benefits

The use of the Cummins Male Connector 3698416 offers several advantages. It provides improved connectivity, ensuring that systems operate smoothly and efficiently. Its durable construction contributes to the longevity of the component, reducing the need for frequent replacements. Additionally, by ensuring reliable connections, it can contribute to cost savings over time by minimizing downtime and the need for repairs.

Installation Considerations

When installing the Cummins Male Connector 3698416, it is important to follow guidelines and best practices to ensure a secure and effective connection. This may involve using specific tools or following particular procedures to achieve the best results. Proper installation is key to maximizing the performance and durability of the connector 3.

Troubleshooting Common Issues

Common problems with male connectors can include loose connections, leaks, or corrosion. Troubleshooting these issues may involve inspecting the connection for signs of wear or damage, ensuring that it is properly seated, or cleaning the connector to remove any corrosion. Addressing these issues promptly can help maintain the efficiency and reliability of the system.

Maintenance Tips

Regular maintenance of the Cummins Male Connector 3698416 is important to ensure its longevity and reliable performance. This may include cleaning the connector to remove dirt or debris, inspecting it for signs of wear or damage, and replacing it if necessary. Following these maintenance tips can help prevent issues and ensure that the connector continues to perform effectively.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. Its product range includes a variety of components and systems designed to enhance the performance and efficiency of commercial vehicles.

Compatibility of Male Connector Part 3698416 with Cummins Engines

This Cummins part is designed to fit seamlessly with a variety of Cummins engines. It is integral to ensuring proper fluid flow and system integrity within the engine’s hydraulic or fuel systems.

ISG11 CM2880 G108 and ISG12 CM2880 G107

These engines, both part of the ISG series, utilize the Male Connector in their hydraulic systems. This connector is important for maintaining the pressure and flow required for optimal engine performance.

ISG12 G CMOH6.0 G111

In the ISG12 G CMOH6.0 G111 engine, the Male Connector plays a role in the engine’s fuel delivery system. It ensures that the fuel is delivered efficiently and without leaks, contributing to the engine’s overall reliability and efficiency.

QSG12/X12 CM2350 G110

For the QSG12/X12 CM2350 G110 engine, the Male Connector is used in the hydraulic system. Its precise fit and robust construction are important for handling the pressures and flows encountered in this engine’s operation.

X11 CM2670 X126B and X12 CM2670 X121B

Both the X11 CM2670 X126B and X12 CM2670 X121B engines incorporate the Male Connector in their respective systems. This part is vital for maintaining the integrity of the connections in the engine’s hydraulic or fuel systems, ensuring smooth and efficient operation.

X12N CMMDG1 X143B and X13 CM2670 X122B

The Male Connector is also compatible with the X12N CMMDG1 X143B and X13 CM2670 X122B engines. In these engines, the connector is used in systems where precise fluid flow and pressure management are critical. Its design ensures that it can withstand the operational demands of these engines, providing long-lasting performance.

Role of Part 3698416 Male Connector in Engine Systems

The Male Connector is integral to the efficient operation of several key engine components. It facilitates the secure and reliable connection between various systems, ensuring optimal performance and longevity of the engine.

Compressor

In the compressor system, the Male Connector ensures a tight seal between the compressor and its associated piping. This connection is important for maintaining the pressure integrity of the compressed air, which is important for the efficient operation of the compressor. A secure connection prevents air leaks, which can lead to inefficiencies and increased wear on the compressor.

Air System

Within the air system, the Male Connector plays a role in linking the air intake to the engine’s air filtration system. This ensures that the air entering the engine is clean and free from contaminants, which is important for maintaining engine performance and preventing damage to internal components.

Engine Oil Cooler

The Male Connector is used in the engine oil cooler system to connect the cooler to the engine’s oil circulation system. This connection allows for the efficient transfer of heat away from the engine oil, which helps in maintaining the oil at an optimal temperature. Proper cooling of the engine oil is important for reducing viscosity changes and ensuring that the oil maintains its lubricating properties.

Lubricating Oil Filter Head

In the lubricating oil filter head, the Male Connector ensures a secure attachment between the filter and the engine’s oil passages. This connection is important for maintaining the integrity of the oil filtration process, ensuring that contaminants are effectively removed from the oil before it circulates through the engine. A reliable connection here prevents bypass scenarios where unfiltered oil could enter the engine, potentially leading to increased wear and reduced engine life.

Conclusion

The Cummins Male Connector 3698416 is a critical component in the operation of commercial trucks, ensuring the efficient and reliable connection of various systems. Its design, durability, and compatibility with a range of Cummins engines make it an essential part for maintaining the performance and longevity of these vehicles. Regular maintenance and proper installation are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.