This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

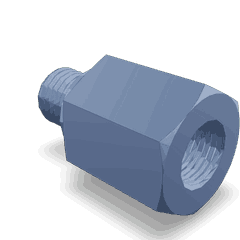

The Cummins 3863672 Female Connector is a specialized component designed for use in commercial trucks. It serves a significant role in the electrical system of these vehicles, facilitating reliable connections that are vital for the proper operation of various truck systems.

Basic Concepts of Female Connectors

A female connector is a type of electrical connector that features a socket or receptacle designed to receive a corresponding male connector. Within a truck’s electrical system, female connectors ensure secure and stable connections between different components, which is crucial for the reliable transmission of electrical signals and power. They play a role in maintaining the integrity of the electrical system by providing a consistent and dependable link between parts 1.

Purpose of the 3863672 Female Connector

The Cummins 3863672 Female Connector is specifically engineered to support the electrical system in commercial trucks. It functions by providing a secure connection point for various electrical components, ensuring that signals and power are transmitted efficiently throughout the system. This connector supports subsystems such as lighting, sensors, and control modules, contributing to the overall functionality and performance of the truck 2.

Key Features

The Cummins 3863672 Female Connector is characterized by several key features that enhance its performance and durability. Its design incorporates robust materials that resist wear and corrosion, ensuring long-lasting use in demanding environments. The connector type is optimized for easy installation and secure connection, featuring a locking mechanism that prevents accidental disconnections. Additionally, it is designed to withstand harsh environmental conditions, including exposure to moisture, dust, and extreme temperatures 3.

Benefits

The Cummins 3863672 Female Connector offers several benefits that contribute to the reliability and efficiency of a truck’s electrical system. Its design ensures improved reliability by providing a stable and secure connection, reducing the risk of electrical faults. The ease of installation allows for quick and straightforward integration into the truck’s electrical system, minimizing downtime. Its resistance to environmental factors ensures that the connector remains functional in various operating conditions, enhancing the overall system efficiency 4.

Installation and Usage

Proper installation of the Cummins 3863672 Female Connector is crucial for ensuring optimal performance and longevity. It is important to follow specific instructions provided by the manufacturer, which may include guidelines on preparing the connection site, aligning the connector correctly, and securing it in place. Precautions should be taken to avoid damaging the connector or the electrical components it connects to, ensuring a clean and secure fit.

Troubleshooting and Maintenance

To maintain the Cummins 3863672 Female Connector in optimal condition, regular inspection and maintenance are recommended. Common issues may include corrosion, loose connections, or damage to the connector. Troubleshooting steps may involve cleaning the connector, tightening connections, or replacing damaged parts. Regular maintenance helps prevent problems and ensures the connector continues to function reliably.

Compatibility and Applications

The Cummins 3863672 Female Connector is designed for use in specific types of trucks and electrical systems. It is compatible with a range of commercial truck models, supporting various applications where reliable electrical connections are required. Its versatility makes it a valuable component in the maintenance and upgrade of truck electrical systems.

Safety Considerations

When working with the Cummins 3863672 Female Connector, it is important to observe safety considerations to avoid damage or injury. Proper handling of the connector and adherence to electrical safety practices are crucial. This includes ensuring that the electrical system is de-energized before installation or maintenance, using appropriate tools, and following all safety guidelines provided by the manufacturer.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and expertise in power systems make it a trusted partner for truck manufacturers and operators worldwide.

Cummins Female Connector 3863672 Compatibility

The Cummins Female Connector part number 3863672 is designed to integrate seamlessly with various engine models, ensuring reliable connections and performance. This part is compatible with the following engine series:

4B3.9 Engines

The 4B3.9 engines benefit from the precision engineering of the 3863672 Female Connector. This component ensures that electrical and fluid connections are secure, reducing the risk of leaks and enhancing overall engine efficiency. Its robust design is tailored to withstand the operational stresses of these engines, providing a dependable solution for maintenance and repairs.

6B5.9 Engines

Similarly, the 6B5.9 engines are well-suited for the 3863672 Female Connector. This part is engineered to fit perfectly within the architecture of the 6B5.9 engines, facilitating smooth and efficient connections. Its compatibility with these engines ensures that the connectors are both durable and easy to install, supporting the engine’s performance and longevity.

Grouping for Efficiency

Both the 4B3.9 and 6B5.9 engines share common design principles and operational requirements, making the 3863672 Female Connector an ideal choice for these models. This grouping highlights the part’s versatility and its ability to enhance the functionality of multiple engine types within the same family. The connector’s design ensures that it meets the specific needs of these engines, providing a reliable and efficient connection solution.

Role of Part 3863672 Female Connector in Engine Systems

The part 3863672 Female Connector is integral to the efficient operation of several engine components, ensuring seamless integration and functionality.

Integration with the Coupling

The Female Connector interfaces directly with the coupling, providing a secure and reliable connection point. This connection is essential for the transfer of mechanical force and fluid, ensuring that the coupling operates within its designed parameters. The secure fit offered by the Female Connector minimizes the risk of leaks or disconnections, which could otherwise lead to inefficiencies or potential safety hazards.

Functionality with the Fuel Pump

In the context of the fuel pump, the Female Connector plays a significant role in maintaining the integrity of the fuel delivery system. It ensures that the fuel lines are properly sealed, preventing any fuel leaks that could pose a fire hazard or lead to a decrease in engine performance. The connection also facilitates the smooth flow of fuel from the tank to the engine, supporting consistent fuel pressure and delivery.

Interaction with the Fuel Pump Coupling

When considering the fuel pump coupling, the Female Connector is responsible for linking the fuel pump to the broader fuel system. This connection is vital for the mechanical and hydraulic operation of the fuel pump. The Female Connector ensures that the coupling can transmit the necessary force and fluid without interruption, which is essential for the fuel pump to function correctly and deliver fuel efficiently to the engine.

Conclusion

In summary, the part 3863672 Female Connector is a key component in maintaining the operational integrity of the coupling, fuel pump, and fuel pump coupling within engine systems. Its role in providing secure, leak-free connections is fundamental to the overall performance and safety of the engine.

-

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩ -

Diesel Engines, A. J. Wharton, Butterworth-Heinemann Ltd, 1991

↩ -

Automotive Maintenance: Light Repair, Rob Thompson, Cengage Learning, 2019

↩ -

Diesel Engine System Design, Qianfan Xin, Woodhead Publishing, 2011

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.