This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

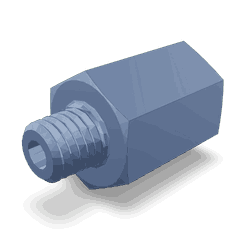

The Cummins 3893801 Female Connector is a specialized component designed for use in commercial truck operations. This connector facilitates the connection between various electrical or fluid systems within the truck, ensuring seamless operation and integration of different subsystems. Its significance lies in its ability to enhance the efficiency and reliability of truck operations, contributing to overall performance and maintenance ease.

Basic Concepts of Female Connectors

Female connectors are components used in both electrical and fluid systems to establish connections between different parts of a system. They are characterized by their receptacle design, which allows them to receive a corresponding male connector. In automotive and industrial settings, female connectors are vital for ensuring secure and efficient connections, which are essential for the operation of complex systems. They help in maintaining the integrity of the connections, reducing the risk of leaks or electrical faults 1.

Purpose of the 3893801 Female Connector

The Cummins 3893801 Female Connector is designed to play a specific role within the truck’s electrical or fluid system. It facilitates the connection between components, allowing for the transfer of electrical signals or fluids as required by the truck’s operation. This connector ensures that the connections are secure, reducing the likelihood of disconnections or failures that could affect the truck’s performance.

Key Features

The Cummins 3893801 Female Connector is distinguished by several key features that enhance its durability and efficiency. It is constructed from high-quality materials that are resistant to wear and environmental factors, ensuring long-term reliability. The design incorporates elements that facilitate easy installation and secure connections, minimizing the risk of errors during assembly. Additionally, it may feature unique attributes such as enhanced sealing mechanisms or corrosion-resistant coatings, which differentiate it from other connectors 2.

Benefits

Utilizing the Cummins 3893801 Female Connector offers several advantages. It contributes to improved system reliability by ensuring secure and stable connections. The ease of installation reduces downtime during maintenance procedures, allowing for quicker turnaround times. Over time, the durability and efficiency of this connector can lead to potential cost savings by minimizing the need for frequent replacements or repairs.

Installation and Usage

Proper installation of the Cummins 3893801 Female Connector is crucial for optimal performance. It should be installed according to the manufacturer’s guidelines, ensuring that all connections are secure and correctly aligned. Best practices include verifying the cleanliness of the connection points and using the appropriate tools to avoid damage. Specific requirements may include torque specifications for tightening connections to ensure they are secure without over-tightening, which could lead to damage 3.

Troubleshooting and Maintenance

Common issues with the Cummins 3893801 Female Connector may include loose connections or signs of wear and damage. Regular inspection and maintenance can help identify these issues early, allowing for timely repairs or replacements. Maintenance tips include cleaning the connector regularly to remove any debris or corrosion and checking for any signs of wear that may indicate the need for replacement. Proper handling and storage when not in use can also extend the connector’s lifespan.

Compatibility and Applications

The Cummins 3893801 Female Connector is designed for use in specific types of trucks and systems. It is commonly applied in models where secure and reliable connections are critical for the operation of electrical or fluid systems. Understanding the compatibility of this connector with specific truck models or systems is important for ensuring optimal performance and integration.

Safety Considerations

When working with the Cummins 3893801 Female Connector, it is important to follow safety protocols to ensure personal safety and the integrity of the system. This includes wearing appropriate personal protective equipment (PPE) and following handling procedures to avoid injury or damage to the connector. Being aware of potential hazards, such as electrical risks or fluid leaks, is also crucial when performing installations or maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Cummins Female Connector 3893801 Compatibility

The Cummins Female Connector part number 3893801 is designed to interface seamlessly with a variety of Cummins engine models. This connector is a critical component in ensuring proper fluid flow and system integrity across different engine configurations. Below is a detailed overview of its compatibility with specific engine models.

K38 and K50 Engines

The Cummins Female Connector 3893801 is compatible with the K38 and K50 engines. These engines are known for their robust design and are often used in heavy-duty applications. The connector’s precise fit ensures that it can handle the high pressures and temperatures typical of these engines, maintaining system efficiency and reliability.

M11 CELECT PLUS and M11 MECHANICAL Engines

For the M11 CELECT PLUS and M11 MECHANICAL engines, the 3893801 Female Connector is engineered to provide a secure and leak-proof connection. The M11 series is renowned for its advanced technology and performance, and this connector is no exception. It is designed to integrate smoothly with the engine’s hydraulic and fuel systems, ensuring optimal performance and longevity.

N14 MECHANICAL Engine

The Cummins Female Connector 3893801 also fits the N14 MECHANICAL engine, which is another staple in the Cummins lineup. This engine is favored for its durability and power, particularly in on-highway and vocational applications. The connector’s compatibility with the N14 MECHANICAL engine ensures that it can withstand the rigorous demands of these environments, providing a dependable connection that enhances overall engine performance.

Role of Part 3893801 Female Connector in Engine Systems

The Part 3893801 Female Connector is integral to the seamless operation of various engine systems by facilitating secure and reliable electrical connections. Its application spans across multiple components, ensuring efficient communication and data transfer within the engine’s electronic network.

Integration with Key Components

-

Electronic Control Module (ECM) Kit: The Female Connector is used to link the ECM to other engine components, allowing for precise control over engine operations. It ensures that the ECM receives accurate data from sensors and can send control signals to actuators.

-

Harness Mounting Kit: This connector plays a role in securing the wiring harness in place, providing a stable connection point that resists vibration and movement, which are common in engine compartments.

-

Injector Plumbing Kit: In the context of fuel injection systems, the Female Connector is employed to connect the injectors to the engine control module, ensuring that fuel delivery is accurately controlled based on engine demand.

-

Cense Upfit Kit: For emission control systems, the connector is vital in linking sensors that monitor exhaust gases to the engine control unit, allowing for real-time adjustments to reduce emissions.

-

Modified Centry Kits (12V and 24V): These kits often require the Female Connector to interface with battery systems, ensuring that the engine’s electrical components receive the correct voltage for operation.

-

Engine Control Module: The connector is used to establish a connection between the engine control module and various sensors and actuators, facilitating the module’s role in managing engine performance.

-

Electronic Engine Monitor: It connects the monitor to the engine’s electrical system, allowing for the collection of performance data and diagnostics.

-

Engine Monitor Mounting: Secure connections are essential for the engine monitor’s mounting system, and the Female Connector ensures that all electrical links are maintained despite the monitor’s position.

-

Oil Control Valve: The connector is utilized to link the oil control valve to the engine’s electronic system, enabling dynamic adjustments to oil flow for optimal engine lubrication.

-

Fuel Pressure Sensor: It connects the sensor to the engine’s electronic system, providing real-time data on fuel pressure to the ECM for fuel management.

-

Engine Monitoring System: The Female Connector is a key component in the engine monitoring system, ensuring that all sensors and control units are interconnected for comprehensive engine oversight.

Conclusion

The Cummins Female Connector 3893801 is a versatile component that fits a range of Cummins engines, including the K38, K50, M11 CELECT PLUS, M11 MECHANICAL, and N14 MECHANICAL models. Its design ensures compatibility and reliability across these engines, making it an essential part for maintaining system integrity and performance. The connector’s role in facilitating secure and reliable electrical connections within engine systems underscores its importance in the efficient operation of commercial trucks.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ -

P. A. Lakshminarayanan and Nagaraj S. Nayak, Critical Component Wear in Heavy Duty Engines, John Wiley & Sons, 2011.

↩ -

Michael Hilgers, Electrical Systems and Mechatronics, Second Edition, Springer Vieweg, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.