This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

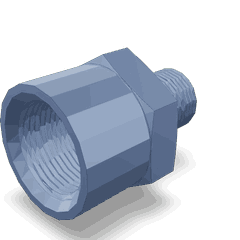

The Cummins 3918497 Female Connector is a specialized component designed for use in heavy-duty truck systems. It plays a role in ensuring the efficient operation of various electrical and fluid systems within these vehicles. Understanding its purpose and functionality is key to maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Female Connectors

A female connector is a type of fitting used in both electrical and fluid systems to facilitate secure and reliable connections. In an electrical system, it allows for the transfer of power between components, while in a fluid system, it enables the flow of liquids or gases. These connectors are widely used in automotive and industrial applications due to their ability to provide a stable and consistent connection, reducing the risk of leaks or electrical faults 1.

Purpose of the Cummins 3918497 Female Connector

The Cummins 3918497 Female Connector is specifically designed to play a role in the electrical or fluid system of a truck. It ensures a secure connection between various components, contributing to the overall efficiency and reliability of the truck’s systems. By providing a stable connection point, it helps in maintaining the integrity of the system it is part of, whether it be for power distribution or fluid transfer.

Key Features

The Cummins 3918497 Female Connector is characterized by its robust design and the quality materials used in its construction. It is engineered to withstand the demanding conditions typical of heavy-duty truck environments. Unique features such as corrosion resistance and high durability enhance its performance, ensuring long-lasting reliability in critical applications 2.

Benefits

Using the Cummins 3918497 Female Connector offers several advantages. It contributes to improved system reliability by ensuring secure connections. Its design also facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, it is compatible with a range of components, making it a versatile choice for various applications within heavy-duty trucks.

Installation Process

Installing the Cummins 3918497 Female Connector requires following a specific procedure to ensure proper functionality. The process involves preparing the connection point, aligning the connector, and securing it in place. Tools and additional components may be required to complete the installation, ensuring a tight and secure fit.

Troubleshooting Common Issues

Common issues with the Cummins 3918497 Female Connector may include connection failures or leaks. Troubleshooting these problems involves inspecting the connector for signs of damage or wear, ensuring it is properly aligned and secured, and checking for compatibility with connected components. Addressing these issues promptly can prevent more significant problems down the line 3.

Maintenance Tips

Regular maintenance of the Cummins 3918497 Female Connector is crucial for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the connector to remove any debris or corrosion, and ensuring all connections remain secure. Following these maintenance tips can help prevent issues and extend the life of the connector.

Safety Considerations

When working with the Cummins 3918497 Female Connector, especially in electrical systems and fluid connections, it is important to observe safety guidelines. This includes ensuring the system is de-energized before beginning work, using appropriate personal protective equipment, and following all manufacturer recommendations for installation and maintenance. Safety is paramount to prevent accidents and ensure the well-being of those working on the equipment.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the automotive and industrial sectors, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name in the industry.

Cummins Female Connector 3918497 Compatibility

The Cummins Female Connector part number 3918497 is designed to ensure seamless integration and reliable performance across various engine models. This part is engineered to fit precisely within the engine systems, facilitating essential functions such as fluid transfer, electrical connections, and other critical operations.

Engine Compatibility

-

6C8.3 Engines

- The 3918497 Female Connector is specifically designed to integrate with the 6C8.3 engine series. Its precise fit ensures that it can handle the unique demands of this engine model, providing durability and reliability in demanding conditions.

-

Other Cummins Engines

- Beyond the 6C8.3, this connector is also compatible with a range of other Cummins engine models. Its versatile design allows it to be used across different engine types, ensuring that it meets the specific requirements of each engine system.

Grouping of Engines

-

Industrial and Commercial Engines

- The 3918497 Female Connector is particularly suited for industrial and commercial engines, where reliability and performance are paramount. Its robust construction and precise fit make it an ideal choice for these applications.

-

Heavy-Duty Engines

- In heavy-duty engines, the 3918497 Female Connector plays a role in maintaining the integrity of the engine’s systems. Its ability to withstand high stress and demanding conditions ensures that it can perform consistently over long periods.

Application Considerations

-

Fluid and Electrical Connections

- The primary function of the 3918497 Female Connector is to facilitate fluid and electrical connections within the engine. Its design ensures that these connections are secure and leak-free, which is essential for the engine’s overall performance and longevity.

-

Maintenance and Durability

- Constructed from high-quality materials, the 3918497 Female Connector is built to last. Its durability ensures that it can withstand the rigors of continuous use, reducing the need for frequent replacements and maintenance.

Role of Part 3918497 Female Connector in Engine Systems

The Part 3918497 Female Connector is integral to the efficient operation of various engine systems. It facilitates the secure connection between different components, ensuring optimal performance and reliability.

Integration with Check Valve

In systems incorporating a check valve, the Female Connector ensures a tight seal, preventing backflow and maintaining the unidirectional flow of fluids. This is particularly important in fuel and hydraulic systems where precise control of fluid direction is necessary.

Connection to Vent

When connected to a vent, the Female Connector allows for the safe release of pressure or gases from the engine compartment. This helps in maintaining a stable internal environment, preventing buildup of harmful pressures that could lead to component failure.

Interaction with Engine Coolant System

In the engine coolant system, the Female Connector plays a role in linking various coolant passages. It ensures that coolant circulates efficiently through the engine block, radiator, and other critical components. This consistent flow is essential for dissipating heat, thereby protecting the engine from overheating and potential damage.

Conclusion

The Cummins 3918497 Female Connector is a critical component in the maintenance and optimization of heavy-duty truck systems. Its robust design, compatibility with various engine models, and role in ensuring secure and reliable connections make it an essential part for any professional working in the automotive or industrial sector. Regular maintenance and adherence to safety guidelines are paramount to maximizing the performance and longevity of this connector.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.