This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

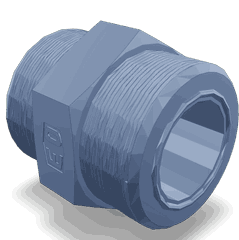

The Cummins 4015365 Male Connector is a component designed for use in commercial truck operations. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is important for maintaining and optimizing truck performance.

Basic Concepts of Male Connectors

A male connector is a type of fitting used to join two components together in a system. It typically features a protruding pin or post that fits into a corresponding female connector. The male connector facilitates the transfer of fluids, gases, or electrical signals between systems, ensuring seamless operation. Its design allows for secure connections that can withstand various pressures and environmental conditions 1.

Purpose of the 4015365 Male Connector

This part plays a role in the truck’s systems by providing a reliable connection point for fluid or electrical transfer. It is integral to maintaining the integrity of the system it is part of, ensuring that components function as intended without leaks or interruptions.

Key Features

The 4015365 Male Connector is characterized by several design elements and materials that enhance its performance. It is constructed from durable materials to resist corrosion and wear. The connector features a precise fit that ensures a secure connection, minimizing the risk of disconnection or leakage. Additionally, it may include sealing elements to further prevent leaks and maintain system pressure.

Benefits of Using the 4015365 Male Connector

Utilizing this Cummins part offers several advantages. Its robust construction contributes to improved durability and reliability in truck operations. The secure connection it provides helps maintain system efficiency, reducing the likelihood of downtime due to connector failure. Furthermore, its design allows for easy installation and replacement, facilitating maintenance procedures.

Installation Process

Installing the 4015365 Male Connector requires careful attention to detail to ensure a proper fit and secure connection. Begin by preparing the connection point, ensuring it is clean and free of debris. Align the male connector with the corresponding female connector and push it in until it is fully seated. Use any provided tools or equipment to secure the connection further, if necessary. Follow manufacturer guidelines for torque specifications to avoid over-tightening.

Troubleshooting Common Issues

Common issues with the 4015365 Male Connector may include leaks, disconnections, or corrosion. To address these problems, first, inspect the connection for any visible damage or wear. Ensure that the connector is properly seated and secured. If corrosion is present, clean the affected areas and apply a suitable corrosion inhibitor. Replace the connector if it shows signs of significant wear or damage.

Maintenance Tips

Regular maintenance of the 4015365 Male Connector is important to ensure its longevity and optimal performance. Inspect the connector periodically for signs of wear, corrosion, or damage. Clean the connection point as needed to remove any debris or buildup. Lubricate moving parts, if applicable, to reduce friction and wear. Follow manufacturer recommendations for maintenance intervals and procedures.

Safety Considerations

When working with the 4015365 Male Connector, it is important to observe safety guidelines and precautions. Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Ensure that the truck is properly shut down and disconnected from power sources before beginning any maintenance or repair work. Follow manufacturer instructions and safety guidelines to avoid accidents or injuries.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to quality and innovation in the commercial truck industry. With a history spanning over a century, Cummins has established itself as a trusted provider of reliable and efficient engine solutions. The company offers a wide range of products and services designed to meet the diverse needs of its customers, from heavy-duty trucks to industrial applications. Cummins’ reputation for excellence is built on its dedication to engineering excellence, customer satisfaction, and sustainable practices 2.

Compatibility with Engine Models

The 4015365 Male Connector is designed to integrate seamlessly with a range of Cummins engine models. This part is crucial for ensuring proper fluid flow and system integrity within the engine’s hydraulic or fuel systems. Here is a detailed look at its compatibility with specific engine models:

QSK95 CM2350 K113

The QSK95 CM2350 K113 engine benefits from the 4015365 Male Connector in its hydraulic system. This connector is engineered to fit precisely within the engine’s design, ensuring that fluid connections are secure and leak-free. Its robust construction and precise fit are essential for maintaining the engine’s performance and longevity.

QSV91-G4 CM558/CM700 V102

Similarly, the QSV91-G4 CM558/CM700 V102 engines also utilize the 4015365 Male Connector. This part is integral to the engine’s hydraulic and fuel systems, providing a reliable connection point that can withstand the rigors of continuous operation. The connector’s design ensures that it fits perfectly within the engine’s architecture, facilitating smooth and efficient fluid transfer.

Grouping of Engine Models

The engines QSK95 CM2350 K113 and QSV91-G4 CM558/CM700 V102 share a commonality in their use of the 4015365 Male Connector. This part is designed to be versatile, fitting into various engine configurations while maintaining the high standards of performance and reliability that Cummins is known for. The connector’s compatibility with these engines underscores its importance in ensuring the smooth operation of the engine’s hydraulic and fuel systems.

Role of the 4015365 Male Connector in Engine Systems

The 4015365 Male Connector is integral to the efficient operation of various engine systems. It facilitates the secure and reliable connection between different components, ensuring optimal performance and functionality.

In the Air Intake System (AID), the Male Connector ensures a tight seal between the intake manifold and the intercooler. This connection is vital for maintaining the correct air pressure and temperature, which directly affects engine performance and efficiency.

Within the Coolant Heater Starting System, the Male Connector plays a key role in connecting the coolant heater to the engine block. This ensures that the coolant is effectively heated before engine start-up, reducing wear on engine components and improving cold-start performance.

For the Charge Air Bypass Plumbing, the Male Connector is used to link the bypass valve to the intake tract. This connection allows for the controlled release of excess charge air, preventing over-pressurization and ensuring stable engine operation under varying load conditions.

In general Plumbing Applications, the Male Connector is employed to join various hoses and pipes within the engine compartment. This includes connections in the fuel system, vacuum lines, and other fluid pathways, ensuring that fluids are transported efficiently and without leaks.

Overall, the Male Connector (Part 4015365) is a fundamental component in maintaining the integrity and performance of these engine systems, contributing to the overall reliability and efficiency of the engine.

Conclusion

The Cummins 4015365 Male Connector is a critical component in the operation of commercial trucks, ensuring reliable and efficient connections within various engine systems. Its robust design, ease of installation, and compatibility with multiple Cummins engine models make it an essential part for maintaining vehicle performance and reliability. Regular maintenance and adherence to safety guidelines are important for maximizing the lifespan and effectiveness of this connector.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.