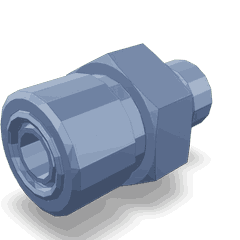

4016669

Male Union

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Male Union Fitting 4016669, manufactured by Cummins, is a critical component in commercial truck applications. It ensures the efficient operation of fluid systems within trucks, meeting the rigorous demands of commercial trucking environments 4.

Basic Concepts of Male Union Fittings

A Male Union Fitting is a pipe fitting used to connect two sections of pipe or tubing. It features a male threaded end that screws into a female counterpart, secured with a union nut. This design allows for easy disassembly and reassembly, making it ideal for systems requiring regular maintenance or modifications 1.

Purpose of the 4016669 Male Union Fitting

The 4016669 Male Union Fitting is designed to connect different components within a truck’s fluid system. It provides secure, leak-proof connections, contributing to the overall efficiency and safety of the truck’s operation. This fitting is commonly used in fuel lines, hydraulic systems, and other fluid transfer applications where durability and performance are essential 2.

Key Features

The 4016669 Male Union Fitting is characterized by several key features:

- Constructed from high-quality materials, ensuring resistance to corrosion and wear.

- Precise threading and a robust union nut provide a secure connection.

- Engineered to withstand high pressure, suitable for demanding applications.

- Facilitates easy installation and removal, beneficial for maintenance purposes 3.

Benefits

Using the 4016669 Male Union Fitting offers several advantages:

- Improved system efficiency due to secure and leak-proof connections.

- Easy installation, reducing downtime during maintenance.

- Durability and resistance to wear contribute to the longevity of the truck’s fluid systems, offering cost-effective maintenance solutions over time 4.

Installation Process

Installing the 4016669 Male Union Fitting requires careful attention to detail:

- Clean the mating surfaces.

- Apply the appropriate sealant if necessary.

- Thread the male end into the female counterpart.

- Tighten the union nut to the manufacturer’s specified torque to ensure a secure fit without over-tightening 1.

Troubleshooting and Maintenance

Common issues with Male Union Fittings include leaks, corrosion, or wear over time. Regular inspection and maintenance are essential:

- Check for signs of corrosion.

- Ensure connections are tight.

- Look for any fluid leaks around the fitting.

- Periodic cleaning and replacement, if necessary, to ensure optimal performance and longevity 2.

Safety Considerations

When working with Male Union Fittings, observe safety guidelines and precautions:

- Understand the pressure ratings of the fitting and ensure it is suitable for the application.

- Follow proper handling procedures to avoid injury or damage to the fitting.

- Ensure the system is depressurized before performing any maintenance or installation work to prevent accidents 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry 4.

Cummins Male Union Fitting 4016669 Compatibility

The Cummins Male Union Fitting part number 4016669 is designed to fit a variety of Cummins engines, ensuring a secure and leak-proof connection. Here is a detailed look at the engines with which this part is compatible:

ISB Series Engines

- ISB CM2150

- ISB6.7 CM2250

QSB Series Engines

- QSB5.9 CM850

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

QSC Series Engines

- QSC8.3 CM850 (CM2850)

QSK Series Engines

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK45 CM500

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

- QSK78 CM500

- QSK95 CM2350 K113

QST Series Engines

- QST30 CM2350 T101

X12 Series Engines

- X12 CM2350 X119B

K Series Engines

- K19

- K38

- K50

This fitting is critical for maintaining the integrity and performance of these engines, ensuring they operate efficiently and reliably 4.

Role of Part 4016669 Male Union Fitting in Engine Systems

The 4016669 Male Union Fitting is an essential component in various engine systems, facilitating the secure connection of different parts and ensuring the efficient flow of fluids and gases. Its applications span across several critical systems within an engine, contributing to overall performance and reliability 1.

Exhaust Recirculation System

In the Exhaust Recirculation (EGR) system, the 4016669 Male Union Fitting connects the EGR valve to the exhaust manifold and the intake manifold. This fitting ensures a leak-free connection, allowing recirculated exhaust gases to mix with the incoming air-fuel mixture, reducing nitrogen oxides (NOx) emissions and improving engine efficiency 2.

Crankcase Ventilation System

The fitting plays a role in the crankcase ventilation system by connecting the breather to the crankcase. This connection allows for the release of pressure built up within the crankcase, preventing oil leaks and maintaining a clean oil supply. The fitting ensures that the ventilation system operates efficiently, contributing to the longevity of engine components 3.

Fuel System

Within the fuel system, the 4016669 Male Union Fitting is utilized to connect the fuel filter to the fuel transfer pump and the fuel filter head. This ensures a consistent and clean fuel supply to the engine, enhancing combustion efficiency and overall engine performance. The fitting’s secure connection prevents fuel leaks, which is vital for safety and reliability 4.

Lubricating Oil System

In the lubricating oil system, the fitting is employed to connect the oil filter cooler to the lubricating oil filter head. This connection ensures that the oil is properly cooled before it is circulated through the engine, maintaining optimal viscosity and preventing overheating. The fitting’s robust design ensures that the oil flow is uninterrupted, supporting the engine’s lubrication needs 1.

Turbocharger Plumbing

For turbocharger systems, the 4016669 Male Union Fitting is used in the plumbing connections for turbocharger coolant. This fitting ensures that the coolant flows efficiently through the turbocharger, maintaining its temperature within safe operating limits. Proper coolant flow is essential for the turbocharger’s performance and durability 2.

Engine Instrumentation and Monitoring

The fitting is also integral in engine instrumentation and monitoring systems. It connects various sensors and gauges, such as those used for flow measurement and exhaust gas recirculation, ensuring accurate data transmission. This data is crucial for engine management systems to make real-time adjustments, optimizing performance and emissions 3.

Corrosion Resistance and System Integrity

Across all these applications, the 4016669 Male Union Fitting’s corrosion-resistant properties ensure that it maintains system integrity over time. This is particularly important in environments where the engine is exposed to harsh conditions, such as high temperatures, moisture, and chemical exposure 4.

Conclusion

The 4016669 Male Union Fitting is a versatile and reliable component that enhances the functionality and efficiency of various engine systems. Its secure and leak-proof connections are vital for the proper operation of exhaust recirculation, crankcase ventilation, fuel, lubricating oil, and turbocharger systems, as well as engine instrumentation and monitoring.

-

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩ ↩ ↩ ↩ -

Reif, K. (Ed.). (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ ↩ ↩ ↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ ↩ ↩ ↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.