This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

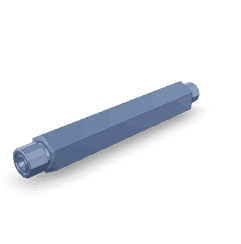

The Injector Cup 4295517, manufactured by Cummins, is a critical component in the fuel injection system of various engines. This part is specifically designed to fit seamlessly with the QST30 CM2350 T101 and QST30 CM552 engines.

Basic Concepts of Injector Cups

An injector cup is a component that houses the fuel injector within the cylinder head of an engine. Its function is to provide a secure and sealed environment for the injector, allowing it to deliver fuel into the combustion chamber effectively 1. The injector cup contributes to the overall performance of the engine by ensuring that fuel is delivered under the correct pressure and in the right quantity, which is crucial for efficient combustion and engine operation.

Purpose of the 4295517 Injector Cup

The 4295517 Injector Cup is designed to maintain fuel pressure and seal the injector within the cylinder head. It plays a role in the operation of a truck engine by providing a robust interface between the injector and the cylinder head, which is subjected to high pressures and temperatures 2. This component ensures that the fuel injector operates within the designed parameters, contributing to the engine’s performance and longevity.

Key Features

The 4295517 Injector Cup is characterized by its design and material, which are selected to withstand the harsh conditions within a diesel engine. It is typically made from materials that offer high resistance to wear and corrosion, ensuring durability and reliability 3. The design of the cup may include features such as precise machining for a tight fit, and it is engineered to accommodate the specific requirements of Cummins engines.

Benefits

The 4295517 Injector Cup offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered under optimal conditions. This can lead to enhanced engine performance, as the fuel is injected with precision, resulting in more complete combustion. Additionally, the reliability of the injector cup is a factor in the overall dependability of the engine, reducing the likelihood of fuel system-related failures.

Installation Process

Installing the 4295517 Injector Cup requires careful attention to detail to ensure a secure fit. The process involves cleaning the cylinder head surface, inspecting the cup for any defects, and using the appropriate tools to install the cup without damaging it. Best practices include torquing the cup to the manufacturer’s specifications and verifying the seal integrity before operating the engine.

Troubleshooting Common Issues

Injector cups can encounter issues such as leaks or failures, which may manifest as poor engine performance or increased emissions. Diagnostic procedures to identify these problems may include visual inspections, pressure tests, and analysis of engine performance data. Addressing these issues promptly can prevent further damage to the engine and ensure continued reliable operation.

Maintenance Tips

To prolong the lifespan of the 4295517 Injector Cup, routine maintenance is recommended. This includes regular inspections for signs of wear or damage, cleaning the cup and surrounding areas to prevent contamination, and following the manufacturer’s guidelines for service intervals. Proper maintenance can help maintain the integrity of the fuel injection system and the overall performance of the engine.

Cummins Corporation Overview

Cummins is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the automotive industry, Cummins is known for its commitment to quality and innovation, particularly in the realm of diesel engines and components. The company’s extensive product range and focus on customer satisfaction have established it as a trusted name in the industry.

Role of Part 4295517 Injector Cup in Engine Systems

The 4295517 Injector Cup is an integral component in the efficient operation of several engine systems. It plays a significant role in the following components:

Plumbing

In the engine’s plumbing system, the 4295517 Injector Cup ensures precise fuel delivery to the combustion chamber. This component helps maintain the correct fuel pressure and flow, which is essential for optimal engine performance and fuel efficiency. It interfaces with the fuel lines and injectors, ensuring a secure and leak-free connection.

Oil Cooler Water Plumbing

The 4295517 Injector Cup also contributes to the oil cooler water plumbing system by assisting in the regulation of engine temperature. It helps in the accurate delivery of cooling fluid to the injectors, which is vital for preventing overheating and ensuring the longevity of engine components. The cup’s design allows for efficient heat dissipation, enhancing the overall cooling efficiency of the system.

Turbocharger

In turbocharged engines, the 4295517 Injector Cup plays a role in maintaining the balance between air and fuel delivery. It ensures that the fuel is injected at the right moment and in the correct quantity to match the increased air intake from the turbocharger. This synchronization is key to maximizing power output while minimizing the risk of engine knock or damage.

Conclusion

Overall, the 4295517 Injector Cup is a vital component that enhances the performance and reliability of these interconnected engine systems. Its role in maintaining fuel pressure, ensuring precise fuel delivery, and contributing to the overall efficiency of the engine cannot be overstated.

-

Diesel Mechanics, First Edition, Frank Sander, Global Media, 2007

↩ -

Design and Development of Heavy Duty Diesel Engines: A Handbook, P. A. Lakshminarayanan and Avinash Kumar, Springer Nature, 2020

↩ -

Heavyduty Electric Vehicles: From Concept to Reality, Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Elsevier, 2021

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.