This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

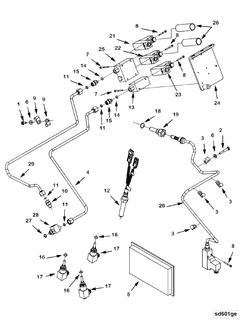

The Cummins 4368341 Female Branch Tee is a component designed for use in commercial trucks. It serves a specific function within the truck’s fluid systems, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Female Branch Tee

A Female Branch Tee is a type of fitting used in fluid systems to connect three different lines, allowing fluid to be distributed or combined. It features one inlet and two outlets, or vice versa, depending on the system’s requirements. In automotive and industrial applications, these fittings are crucial for managing fluid flow, whether it be for coolant, fuel, or other liquids. They enable the system to branch off in multiple directions, facilitating complex fluid dynamics within the vehicle 1.

Purpose of the Cummins 4368341 Female Branch Tee

The Cummins 4368341 Female Branch Tee plays a role in the fluid distribution and management within a truck. It allows for the connection of multiple lines, ensuring that fluid can be directed to various parts of the system as needed. This component is integral to maintaining the correct fluid levels and pressures throughout the truck, contributing to its efficient operation 2.

Key Features

The Cummins 4368341 Female Branch Tee is constructed with specific features that enhance its performance and durability. It is made from materials that resist corrosion and wear, ensuring longevity in demanding environments. The fitting includes precise threading for secure connections and is designed to withstand high pressures and temperatures. These features contribute to its reliability and effectiveness in commercial truck applications 3.

Benefits

Using the Cummins 4368341 Female Branch Tee offers several advantages. It improves fluid flow within the system, reducing the likelihood of blockages or restrictions. The design of the fitting also contributes to reduced maintenance requirements, as its durable construction minimizes the need for frequent replacements. Additionally, the efficient distribution of fluid can enhance the overall efficiency of the truck’s systems.

Installation Considerations

Proper installation of the Cummins 4368341 Female Branch Tee is vital for ensuring optimal performance and longevity. It is important to follow manufacturer guidelines for torque specifications and connection procedures to prevent leaks and ensure a secure fit. Careful attention to the orientation and alignment of the fitting within the system is also necessary to maintain proper fluid dynamics.

Troubleshooting and Maintenance

Common issues with the Cummins 4368341 Female Branch Tee may include leaks, blockages, or corrosion. Regular inspection and maintenance can help identify and address these problems before they lead to system failures. Cleaning the fitting and its connections, as well as monitoring fluid levels and pressures, are important practices for maintaining the component’s functionality.

Safety Considerations

When working with the Cummins 4368341 Female Branch Tee, it is important to observe safety guidelines to protect personnel and maintain system integrity. This includes wearing appropriate personal protective equipment, ensuring the system is depressurized before making any connections or disconnections, and following all manufacturer safety recommendations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for reliability and performance in the automotive and industrial sectors. The company’s extensive product range includes components like the 4368341 Female Branch Tee, which are designed to meet the demanding requirements of commercial applications.

Cummins Female Branch Tee 4368341 in Engine Applications

The Cummins Female Branch Tee part number 4368341 is a critical component in the engine systems of several Cummins engine models. This part is designed to facilitate the connection of various fluid lines, ensuring efficient fluid flow and pressure management within the engine’s system.

QSK50 CM2150 Engines

In the QSK50 CM2150 engines, the Female Branch Tee 4368341 is utilized to connect multiple fluid lines, ensuring that the engine operates smoothly and efficiently. This part is integral in maintaining the integrity of the engine’s fluid pathways, which is crucial for the overall performance and longevity of the engine.

QSK50 CM2150 MCRS and QSK60 CM850 MCRS Engines

Similarly, in the QSK50 CM2150 MCRS and QSK60 CM850 MCRS engines, the Female Branch Tee 4368341 plays a vital role in the engine’s fluid management system. This part is designed to handle the specific demands of these engines, ensuring that fluid lines are securely connected and that there is no leakage or pressure loss. The robust design of the Female Branch Tee 4368341 makes it suitable for the high-performance requirements of these engines.

The use of the Cummins Female Branch Tee 4368341 across these engine models highlights its versatility and importance in maintaining the efficiency and reliability of Cummins engines.

Role of Part 4368341 Female Branch Tee in Engine Systems

The part 4368341 Female Branch Tee is an essential component in the integration and functionality of various engine systems. Its primary role is to facilitate the branching of fluid or gas pathways within the engine, ensuring efficient distribution and management of these substances.

Integration with Engine Monitoring Systems

In engine monitoring systems, the Female Branch Tee allows for the division of sensor lines, enabling multiple sensors to monitor different aspects of engine performance simultaneously. This component ensures that pressure, temperature, and flow rate sensors receive accurate readings by providing a consistent and uncontaminated flow of the substance being measured. The Tee’s design supports the maintenance of precise sensor calibration, which is vital for the reliable operation of the engine monitoring system.

Contribution to Overall System Efficiency

The Female Branch Tee contributes to the overall efficiency of the engine system by optimizing the flow dynamics of fluids and gases. By allowing for the strategic placement of branches, it reduces the need for additional components that would otherwise complicate the system. This simplification leads to fewer points of failure and easier maintenance. Additionally, the Tee helps in maintaining consistent pressure levels across different parts of the engine, which is essential for the stable operation of various engine components.

Enhanced Diagnostic Capabilities

In diagnostic applications, the Female Branch Tee plays a significant role by providing access points for testing and sampling. Engineers and mechanics can use these branches to insert diagnostic tools or take samples without disrupting the main flow. This capability is particularly useful in identifying leaks, contaminants, or other issues within the engine system, allowing for timely interventions and preventing potential failures.

Support for System Upgrades and Modifications

The versatility of the Female Branch Tee makes it an invaluable component during system upgrades or modifications. Its design allows for the easy addition of new sensors or the rerouting of existing lines without extensive rework. This flexibility is particularly beneficial in research and development environments where engine systems are frequently updated to test new technologies or improve performance.

Conclusion

The Cummins 4368341 Female Branch Tee is a fundamental element in the design and operation of engine systems, enhancing efficiency, diagnostic capabilities, and system flexibility. Its role in fluid distribution, integration with monitoring systems, contribution to system efficiency, and support for diagnostics and modifications underscores its importance in maintaining the performance and reliability of commercial truck engines.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.