This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

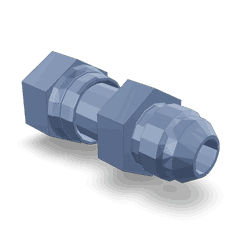

The Cummins 4385462 Hydraulic Pump Support is a component designed for heavy-duty trucks. It plays a role in supporting the hydraulic pump, which is integral to the operation of hydraulic systems in commercial trucks. Hydraulic systems are vital for various truck functions, including braking, steering, and lifting operations. Understanding the components that make up these systems, such as the 4385462, is important for maintaining the efficiency and reliability of heavy-duty trucks.

Basic Concepts of Hydraulic Pump Support

Hydraulic systems in trucks operate on the principles of fluid dynamics, where liquid is used to transmit force. The hydraulic pump is a central component that pressurizes the hydraulic fluid, which then powers various hydraulic actuators throughout the truck. The 4385462 contributes to the overall functionality of the hydraulic system by providing a stable mounting point for the hydraulic pump. This ensures that the pump remains securely in place and operates efficiently under the dynamic conditions experienced by heavy-duty trucks.

Purpose of the 4385462

The 4385462 is designed to support the hydraulic pump, ensuring it remains fixed and operates within specified parameters. By providing a robust mounting solution, this component helps maintain the alignment and stability of the pump, which is important for the consistent performance of the hydraulic system. It also plays a role in dissipating vibrations and reducing stress on the pump, which can enhance its operational lifespan.

Key Features

The 4385462 is engineered with several key features that enhance its performance and durability. Its design incorporates materials that are resistant to corrosion and wear, ensuring longevity in harsh operating environments. The support is also designed to accommodate various pump sizes and configurations, providing versatility for different truck models. Additionally, it includes features that facilitate easy installation and maintenance, reducing downtime for truck operators.

Benefits

The use of the 4385462 offers several benefits. It contributes to the improved reliability of the hydraulic system by ensuring the pump is securely mounted. This can lead to enhanced performance of the hydraulic functions, such as more responsive braking and steering. Moreover, by reducing wear and stress on the pump, the support can increase the longevity of the hydraulic components, potentially lowering maintenance costs over time.

Installation Process

Installing the 4385462 involves several steps to ensure it is properly secured and aligned. Before installation, it is important to ensure that the mounting surface is clean and free of any debris. The necessary tools, such as wrenches and torque wrenches, should be prepared. The support should be positioned according to the manufacturer’s guidelines, and all fasteners should be tightened to the specified torque settings. It is also important to verify that the pump is correctly aligned with the support to prevent operational issues.

Troubleshooting Common Issues

Common issues with the 4385462 may include misalignment, wear, or damage to the mounting points. If the pump appears to be misaligned, it may be necessary to re-evaluate the installation process to ensure all components are correctly positioned. Signs of wear or corrosion on the support may indicate the need for replacement or repair. Regular inspections can help identify these issues early, allowing for timely maintenance.

Maintenance Tips

Regular maintenance of the 4385462 is important for ensuring optimal performance and longevity. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the support and its mounting area can prevent the accumulation of debris that may affect performance. If any components show signs of excessive wear, they should be replaced to maintain the integrity of the hydraulic system.

About Cummins

Cummins is a well-established manufacturer with a strong reputation in the industry for producing high-quality automotive components. The company has a history of innovation and commitment to quality, which is reflected in its product line, including the 4385462. Cummins’ dedication to research and development ensures that its components meet the demanding requirements of heavy-duty truck applications.

Hydraulic Pump Support for Cummins Engines

The Hydraulic Pump Support part number 4385462, manufactured by Cummins, is a critical component designed to ensure the stability and efficiency of the hydraulic systems in various Cummins engines. This part is integral to maintaining the operational integrity of the engines it is used in.

QSK95 and CM2350 Engines

In the QSK95 and CM2350 engines, the Hydraulic Pump Support plays a pivotal role in securing the hydraulic pump. This ensures that the pump operates smoothly and efficiently, reducing wear and tear on the engine components. The design of the support allows for precise alignment and minimizes vibrations, which can lead to premature failure of the pump and other connected parts.

K113 Engine

For the K113 engine, the Hydraulic Pump Support is equally important. It provides a robust mounting solution that supports the hydraulic pump under various operating conditions. This support is crucial for maintaining the pump’s performance and longevity, ensuring that the engine’s hydraulic system functions optimally.

Grouping of Engines

The Hydraulic Pump Support part number 4385462 is compatible with the QSK95 and CM2350 engines, which are part of Cummins’ lineup of heavy-duty diesel engines. These engines are known for their durability and reliability, often used in demanding applications such as construction, mining, and power generation. The K113 engine, while distinct, also benefits from this support in maintaining the integrity of its hydraulic system.

By ensuring that the hydraulic pump is securely mounted, the Hydraulic Pump Support helps to maintain the overall efficiency and reliability of these engines, making it an essential component for their operation.

Role of Part 4385462 Hydraulic Pump Support in Engine Systems

The hydraulic pump support, part 4385462, is integral to the efficient operation of various engine systems. It provides a stable mounting platform for the hydraulic pump, ensuring that the pump remains securely in place during engine operation. This stability is essential for maintaining the alignment of the pump’s inlet and outlet ports, which are connected to the hydraulic lines.

In the context of the alarm system, the hydraulic pump support plays a supportive role by ensuring that the hydraulic pump, which may be used to power certain alarm mechanisms or fluid-driven components, operates smoothly and without undue stress. The consistent performance of the hydraulic pump is vital for the reliable activation of alarm signals, which may include auditory alarms, visual indicators, or other alert systems integrated within the engine’s control framework.

Moreover, the hydraulic pump support contributes to the overall integrity of the hydraulic system by reducing vibrations that could otherwise be transmitted to the pump. This reduction in vibration helps in prolonging the lifespan of the hydraulic components and ensures that the fluid dynamics within the system remain optimal. The support also aids in the dissipation of heat generated by the pump, which is particularly important in high-stress environments where thermal management is a concern.

Conclusion

In summary, part 4385462 hydraulic pump support is a foundational element that enhances the reliability and performance of the hydraulic pump within engine systems, indirectly supporting the functionality of connected components such as the alarm system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.