This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

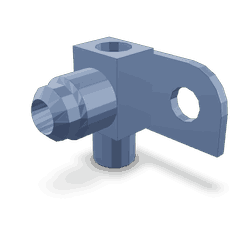

The Cummins 4966487 Female Run Tee is a component designed for use in commercial truck systems. It serves to facilitate the efficient movement of fluids within the truck’s hydraulic or fuel systems. This part is significant for maintaining the smooth operation of these systems, ensuring that fluid dynamics are optimized for performance and reliability.

Basic Concepts of a Female Run Tee

A Female Run Tee is a type of fitting used in fluid systems to connect three pipes or hoses together. It allows fluid to flow from one line into two others, or vice versa, without interrupting the flow. The basic principles of fluid dynamics that apply to its operation include the conservation of mass and energy, ensuring that the fluid flow is directed efficiently and pressure is maintained across the system 1.

Purpose of the 4966487 Female Run Tee in Truck Operations

The 4966487 Female Run Tee plays a role in the operation of a truck by directing fluid flow within the hydraulic or fuel systems. It helps in maintaining consistent pressure throughout the system, which is vital for the efficient performance of the truck. By ensuring that fluid is distributed correctly, it contributes to the overall reliability and effectiveness of the truck’s systems 2.

Key Features

The 4966487 Female Run Tee is characterized by several key features that enhance its durability and performance. These include its material composition, which is designed to withstand the pressures and temperatures of commercial truck systems, and its connection types, which are engineered for secure and leak-free fittings. The design specifications of this part are tailored to meet the demanding requirements of heavy-duty applications 3.

Benefits of Using the 4966487 Female Run Tee

The use of the 4966487 Female Run Tee offers several advantages. It contributes to improved system efficiency by ensuring that fluid is directed accurately and pressure is maintained. This can lead to reduced maintenance needs, as the part is designed to be durable and reliable. Additionally, its integration into truck systems enhances overall reliability, supporting consistent performance.

Installation Considerations

When installing the 4966487 Female Run Tee, it is important to follow guidelines and best practices to ensure proper integration into the system. This includes ensuring proper alignment of the fitting, adhering to torque specifications for secure connections, and verifying compatibility with existing system components. Careful installation helps to prevent issues such as leaks or blockages.

Troubleshooting Common Issues

Common problems associated with the 4966487 Female Run Tee may include leaks or blockages. To address these issues, a systematic approach to troubleshooting is recommended. This involves inspecting the fitting for signs of damage or wear, checking connections for tightness, and ensuring that the system is free from obstructions. Step-by-step methods can help diagnose and resolve these problems effectively.

Maintenance Tips

Regular maintenance practices are important for ensuring the longevity and optimal performance of the 4966487 Female Run Tee. This includes conducting inspections at recommended intervals to check for signs of wear or damage, and following cleaning procedures to remove any buildup that could affect performance. Adhering to these maintenance tips helps to preserve the integrity of the fitting and the efficiency of the system.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and automotive markets. The company’s product range includes engines, components, and technologies that power equipment and vehicles around the world, demonstrating a dedication to advancing the industry through technology and expertise.

Female Run Tee (Part 4966487) Compatibility with Cummins Engines

The Female Run Tee, identified by part number 4966487 and manufactured by Cummins, is a crucial component in the engine systems of various Cummins engines. This part is designed to facilitate the connection of fluid lines, ensuring a secure and leak-proof interface. Below is a detailed description of its compatibility with specific Cummins engine models.

ISM CM570/870 Engines

The ISM CM570/870 engines are part of Cummins’ lineup of industrial and marine engines, known for their robust performance and reliability. The Female Run Tee (4966487) is integral to these engines, providing a necessary connection point for various fluid lines. Its design ensures that it can withstand the high pressures and temperatures typical of these engine environments, contributing to the overall efficiency and longevity of the engine system.

ISM CM876 Engines

Similarly, the ISM CM876 engines benefit from the use of the Female Run Tee (4966487). This engine model is also designed for industrial and marine applications, where durability and performance are paramount. The Female Run Tee in this context is engineered to meet the stringent requirements of these engines, ensuring that fluid lines are securely connected and maintained under demanding conditions.

Grouping of Engines

Both the ISM CM570/870 and ISM CM876 engines fall under the category of industrial and marine engines, which share common design principles and operational requirements. The Female Run Tee (4966487) is compatible with these engines due to its robust construction and precise fit, which is essential for maintaining the integrity of the engine’s fluid systems. This compatibility underscores the versatility and reliability of Cummins components in supporting a range of engine models.

Role of Part 4966487 Female Run Tee in Fuel Plumbing Systems

In fuel plumbing systems, the 4966487 Female Run Tee is instrumental in facilitating the efficient distribution and management of fuel flow. This component is typically integrated into the fuel lines where branching or merging of fuel paths is required.

Fuel Distribution

The primary function of the 4966487 Female Run Tee is to allow fuel to be directed from a single source to multiple destinations or to combine fuel from multiple sources into a single line. This is particularly important in systems where fuel needs to be supplied to various engine components or where fuel from different tanks needs to be merged before entering the engine.

Pressure Management

By enabling the division or combination of fuel lines, the 4966487 Female Run Tee helps in maintaining consistent fuel pressure across the system. This is essential for ensuring that all engine components receive the correct amount of fuel, which is vital for optimal engine performance and efficiency.

System Flexibility

The incorporation of the 4966487 Female Run Tee into fuel plumbing systems provides engineers and mechanics with the flexibility to design and modify fuel lines according to specific engine requirements or configurations. This adaptability is particularly beneficial in custom engine builds or when retrofitting existing systems.

Safety and Efficiency

Proper use of the 4966487 Female Run Tee contributes to the overall safety and efficiency of the fuel system. By ensuring that fuel is correctly distributed and pressures are maintained, the risk of fuel starvation or over-pressurization is minimized, leading to a more reliable and efficient engine operation.

Conclusion

In summary, the 4966487 Female Run Tee plays a significant role in the effective management of fuel within plumbing systems, enhancing both the performance and safety of the engine. Its compatibility with various Cummins engines underscores its versatility and reliability in supporting a range of engine models.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.