This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

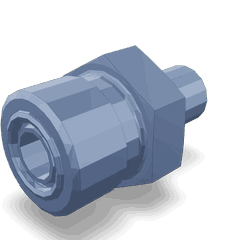

The Cummins 4996937 Male Connector is a specialized component designed for use in commercial truck operations. It plays a role in ensuring the efficient and reliable operation of various systems within these vehicles. Understanding its purpose and functionality is key to maintaining and optimizing truck performance.

Basic Concepts of Male Connectors

A male connector is a type of fitting used in both electrical and fluid systems to join two components together. It typically features a protruding pin or plug that fits into a corresponding female connector. The operation of a male connector is based on the principles of secure connection and efficient transfer of either electrical signals or fluids. These connectors are designed to provide a stable and leak-free connection, ensuring the smooth operation of the system they are part of 1.

Purpose of the 4996937 Male Connector

The 4996937 Male Connector from Cummins is specifically engineered to play a role in the electrical or fluid systems of commercial trucks. Its application can vary, but it is commonly used in scenarios where a secure and reliable connection is required. This could include electrical systems where it ensures the proper transmission of signals or in fluid systems where it maintains the integrity of the fluid transfer process 2.

Key Features

The 4996937 Male Connector is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to wear and corrosion, ensuring longevity in demanding environments. The design of the connector includes precise engineering to ensure a snug fit with corresponding female connectors, minimizing the risk of disconnection or leaks. Additionally, it may feature unique characteristics such as enhanced sealing mechanisms or easy-to-use locking systems that further contribute to its reliability and ease of use 3.

Benefits

Utilizing the 4996937 Male Connector offers several advantages. Its robust construction and precise design contribute to improved reliability, reducing the likelihood of system failures. The ease of installation is another benefit, as the connector is designed to be user-friendly, allowing for quick and straightforward integration into existing systems. Over time, the durability and reliability of this connector can lead to potential cost savings by minimizing the need for frequent replacements or repairs.

Installation Process

Installing the 4996937 Male Connector involves a series of steps to ensure a proper and secure connection. First, identify the location where the connector will be installed and ensure the area is clean and free of debris. Next, align the connector with the corresponding female connector and push it in until it locks into place. Depending on the specific application, tools such as wrenches or screwdrivers may be required to secure the connection further. Always refer to the manufacturer’s guidelines for specific instructions and safety precautions.

Troubleshooting Common Issues

Common issues with the 4996937 Male Connector may include difficulty in connection, leaks, or electrical faults. To troubleshoot these problems, first, ensure that the connector is properly aligned and fully inserted into the female connector. Check for any signs of damage or wear that may prevent a secure connection. In the case of fluid systems, inspect the seals and gaskets for integrity. For electrical connections, verify that there are no loose wires or corrosion that could affect signal transmission. Addressing these issues promptly can help maintain the efficiency and reliability of the system.

Maintenance Tips

Regular maintenance of the 4996937 Male Connector is key to ensuring its longevity and optimal performance. Inspect the connector regularly for signs of wear, corrosion, or damage. Clean the connector and surrounding area to remove any dirt or debris that could affect its operation. Lubricating moving parts, if applicable, can also help maintain smooth operation. Following these maintenance practices can extend the life of the connector and ensure it continues to perform reliably.

Compatibility and Applications

The 4996937 Male Connector is designed to be compatible with a range of commercial trucks and systems. Its versatility allows it to be used in various applications, from electrical systems requiring secure signal transmission to fluid systems needing reliable fluid transfer. Understanding the specific compatibility and applications of this connector can help in selecting the right component for your truck’s needs.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a trusted partner for commercial vehicle operators worldwide.

Compatibility of Male Connector Part 4996937 with Cummins Engines

The Male Connector part number 4996937, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines, ensuring robust and reliable connections. This part is particularly compatible with the following engine models:

- B3.3

- QSB3.3 CM2150

- QSB3.3 CM2250 EC

These engines, while differing in specifications and applications, share a commonality in their need for high-quality connectors to maintain operational efficiency and safety. The Male Connector part 4996937 is engineered to fit these engines, providing a secure and durable connection that is essential for the proper functioning of the engine’s systems.

For the B3.3 engine, the connector ensures that all fluid and air passages are properly sealed, preventing leaks and maintaining system integrity. In the QSB3.3 CM2150 and QSB3.3 CM2250 EC engines, the connector’s design supports the more complex requirements of these models, including higher pressure and temperature tolerances. The EC variant, in particular, benefits from the connector’s ability to withstand additional stresses, ensuring longevity and reliability in demanding environments.

The compatibility of the Male Connector part 4996937 across these engines underscores Cummins’ commitment to providing parts that meet the diverse needs of their engine lineup. This part is a testament to Cummins’ focus on quality and performance, ensuring that users can rely on their engines to operate smoothly and efficiently.

Role of Part 4996937 Male Connector in Engine Systems

The part 4996937 Male Connector is integral to the efficient operation of various engine systems by ensuring secure and reliable connections between components. Its application spans across multiple systems, enhancing performance and safety.

Fuel System Integration

In the fuel system, the Male Connector is used to join fuel lines, ensuring a leak-free pathway from the fuel tank to the engine. This connection is vital for maintaining consistent fuel pressure and flow, which directly impacts engine performance and fuel efficiency. The secure fitting prevents fuel leaks, which are hazardous and can lead to engine malfunctions.

Air and Compressor Systems

Within the air and compressor systems, the Male Connector plays a significant role in linking air intake components to the compressor. This ensures that the air supply to the engine is uninterrupted and clean, which is essential for optimal combustion. In turbocharged engines, it connects the turbocharger to the air intake system, allowing for efficient air compression and delivery, thereby enhancing engine power and responsiveness.

Plumbing and Cooling Systems

The Male Connector is also employed in the engine’s plumbing and cooling systems. It connects various coolant lines, ensuring that the engine maintains optimal operating temperatures. Efficient coolant flow is necessary to prevent overheating and maintain engine longevity. Additionally, it is used in oil systems to connect oil lines, ensuring proper lubrication of moving parts within the engine.

Cylinder and Block Assemblies

In cylinder and cylinder block assemblies, the Male Connector is used to link various fluid lines and sensors. This includes connections for oil, coolant, and fuel lines that run through or around the cylinder block. Secure connections here are essential for the structural integrity and performance of the engine block, ensuring that all fluids are delivered where needed without leaks.

Long Block Applications

For long block applications, which include the cylinder block, crankshaft, pistons, and other essential components, the Male Connector ensures that all necessary fluid lines are properly attached. This is particularly important in high-performance engines where precise fluid management is required to maintain engine health and performance under demanding conditions.

Turbocharger Systems

In turbocharger systems, the Male Connector is used to link the turbocharger to the engine’s air intake and exhaust systems. This ensures that the turbocharger receives the necessary air flow to function efficiently, which is critical for boosting engine performance. Secure connections here prevent air leaks, which can reduce turbocharger efficiency and engine power.

Overall, the part 4996937 Male Connector is a versatile component that enhances the reliability and performance of various engine systems by providing secure and efficient connections.

Conclusion

The Cummins 4996937 Male Connector is a critical component in the operation of commercial truck engines, ensuring secure and reliable connections across various systems. Its robust construction, precise design, and compatibility with a range of Cummins engines make it an essential part for maintaining engine efficiency and safety. Regular maintenance and proper installation are key to maximizing the benefits of this connector, contributing to the overall performance and longevity of the engine systems it serves.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.