This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

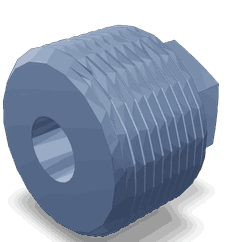

The 5261067 Female Connector, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part is integral to the electrical and fluid systems of trucks.

Basic Concepts of Female Connectors

A female connector is a type of fitting used in electrical or fluid systems to join two components together. It typically features a socket or cavity that allows a male connector to be inserted and secured, creating a sealed connection. In automotive and industrial settings, female connectors are used to ensure secure and reliable connections in various systems, including fuel lines, hydraulic systems, and electrical circuits 1.

Purpose of the 5261067 Female Connector

The 5261067 Female Connector plays a specific role in the operation of a truck by facilitating secure connections within the truck’s electrical or fluid systems. It is designed to ensure that connections are tight and leak-free, which is vital for the proper functioning of the truck’s systems. This connector is often used in applications where reliability and durability are paramount 2.

Key Features

The 5261067 Female Connector is characterized by several key features that enhance its performance and durability. These include a robust material composition, typically made from high-quality plastics or metals that can withstand harsh operating conditions. The design elements of the connector, such as its precise fit and secure locking mechanism, ensure that it remains firmly in place even under vibration or stress. Additionally, any unique attributes, such as corrosion resistance or temperature tolerance, further contribute to its reliability 3.

Benefits

The advantages provided by the 5261067 Female Connector include improved system reliability, as it ensures that connections remain secure and leak-free. Its design also facilitates ease of installation, allowing for quick and straightforward setup without the need for specialized tools. Furthermore, the connector offers maintenance benefits, such as simplified inspection and replacement processes, which contribute to the overall efficiency of truck maintenance routines.

Installation Guidelines

Proper installation of the 5261067 Female Connector involves several steps to ensure a secure and reliable connection. Begin by ensuring that the mating surface is clean and free of debris. Align the connector with the male fitting and press firmly until it locks into place. Verify the connection by checking for any signs of leakage or looseness. Tools or additional components required may include a torque wrench for tightening and a cleaning brush for preparing the mating surface.

Troubleshooting Common Issues

Common problems associated with female connectors can include loose connections, leaks, or corrosion. To troubleshoot these issues, first, inspect the connector for any visible damage or wear. Ensure that the male fitting is clean and free of debris before reinserting it into the female connector. If corrosion is present, clean the affected areas with a suitable solvent and reapply any necessary sealants. Regular inspection and maintenance can help prevent these issues from occurring.

Maintenance Tips

To ensure the longevity and optimal performance of the 5261067 Female Connector, regular maintenance is recommended. This includes cleaning the connector and its mating surfaces to remove any dirt or debris that could affect the connection. Inspect the connector for signs of wear or damage, and replace it if necessary. Additionally, ensure that all connections are tight and secure during routine maintenance checks.

Safety Considerations

When working with the 5261067 Female Connector, especially concerning electrical systems, it is important to observe several safety guidelines. Ensure that the truck’s power is turned off before beginning any work on electrical connections. Use insulated tools to prevent electrical shocks, and wear appropriate personal protective equipment (PPE) such as gloves and safety glasses. Follow all manufacturer recommendations for safe handling and installation of the connector.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance parts and systems. The company’s extensive product range and commitment to innovation make it a trusted name among fleet operators and maintenance professionals.

Cummins Engine Compatibility with Female Connector Part 5261067

The Cummins Female Connector part number 5261067 is a versatile component that fits into various engine models, ensuring seamless integration and reliable performance. This part is designed to interface with multiple engine types, providing a standardized connection point for various systems.

QSB6.7 Series

The QSB6.7 CM2250 and QSB6.7 CM850 (CM2850) engines are part of the QSB6.7 series, which are known for their robust performance and reliability. The Female Connector part 5261067 is compatible with these engines, facilitating connections that are critical for the engine’s operation. This compatibility ensures that the connector can be used across different configurations within the QSB6.7 series, providing a consistent and reliable connection point.

QSB7 Series

The QSB7 CM2880 B117 engine is another model where the Female Connector part 5261067 is applicable. This engine, part of the QSB7 series, benefits from the standardized design of the connector, which allows for easy installation and maintenance. The connector’s design ensures that it fits perfectly with the QSB7 series, maintaining the integrity of the engine’s systems.

QSC9 and QSL9 Series

The QSC9 CM2250 and QSL9 CM2250 engines are part of the QSC9 and QSL9 series, respectively. Both engines are designed for high performance and efficiency. The Female Connector part 5261067 is compatible with these engines, providing a reliable connection point that is essential for the proper functioning of the engine’s systems. This compatibility extends to the QSL9 CM2350 L102 engine as well, ensuring that the connector can be used across different models within the QSL9 series.

The compatibility of the Female Connector part 5261067 across these various engine models highlights its versatility and importance in maintaining the integrity and performance of Cummins engines. This part is a critical component that ensures seamless integration and reliable operation across different engine configurations.

Role of Part 5261067 Female Connector in Engine Systems

The part 5261067 Female Connector is instrumental in ensuring the seamless operation of various engine systems. Its primary function is to facilitate secure and reliable connections between different components, enhancing the overall efficiency and performance of the engine.

Location and Integration

In the engine compartment, the Female Connector is strategically positioned to interface with multiple systems. It is commonly found in areas where fluid transfer and electrical connections are necessary, ensuring that all components operate in unison.

Corrosion Resistance

One of the significant advantages of using the Female Connector is its corrosion-resistant properties. This feature is particularly beneficial in environments where exposure to moisture and chemicals is high, such as near the engine coolant system. The connector’s ability to withstand corrosion ensures long-term reliability and reduces the need for frequent replacements.

Plumbing Systems

Within the plumbing systems of an engine, the Female Connector plays a vital role in maintaining the integrity of fluid lines. It ensures that connections between hoses and fittings remain tight and secure, preventing leaks that could lead to engine damage or decreased performance. This is especially important in high-pressure systems where even a small leak can have significant consequences.

Turbocharger Applications

In turbocharged engines, the Female Connector is often used to link various components of the turbocharger system. It ensures that the air intake and exhaust systems are properly sealed, allowing the turbocharger to operate efficiently. This results in improved airflow and better overall engine performance.

Vent Systems

The Female Connector is also integral to the vent systems within an engine. It helps maintain proper pressure levels by ensuring that vent lines are securely connected. This is essential for preventing the buildup of excessive pressure, which could lead to component failure or reduced engine efficiency.

Engine Coolant System

In the engine coolant system, the Female Connector is used to join different sections of the cooling circuit. This ensures that coolant flows smoothly through the engine, maintaining optimal temperature levels. Efficient coolant flow is vital for preventing overheating and ensuring the engine operates within safe temperature ranges.

Conclusion

Overall, the part 5261067 Female Connector is a versatile component that enhances the functionality and reliability of various engine systems. Its role in securing connections, resisting corrosion, and facilitating fluid transfer makes it an essential part of modern engine design.

-

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.