This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

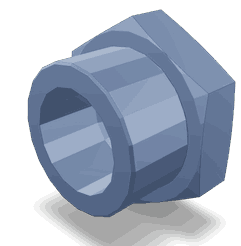

The Cummins 3002075 Female Connector is a specialized component designed for use in commercial truck systems. It serves as an interface in various electrical and fluid systems, ensuring reliable connections and efficient operation. Understanding its purpose and functionality is key to maintaining and optimizing truck performance.

Basic Concepts of Female Connectors

Female connectors are devices that receive a male counterpart to establish a connection within a system. They are integral in both automotive and industrial applications, facilitating the transfer of electrical signals, fluids, or gases. These connectors are designed to provide secure, leak-proof connections that withstand environmental stresses and operational demands 1.

Purpose of the 3002075 Female Connector

The Cummins 3002075 Female Connector plays a specific role in the operation of commercial trucks. It is utilized within the truck’s electrical or fluid systems to ensure seamless connectivity. This connector allows for the efficient transfer of signals or fluids, contributing to the overall functionality and reliability of the truck’s systems 2.

Key Features

The Cummins 3002075 Female Connector is constructed from high-quality materials, ensuring durability and resistance to corrosion. Its design includes precise connection types that guarantee a secure fit, minimizing the risk of disconnection or leakage. The connector is engineered to meet stringent performance standards, enhancing its reliability in demanding truck applications 3.

Benefits

Using the Cummins 3002075 Female Connector offers several advantages. It contributes to improved system efficiency by ensuring stable and consistent connections. Additionally, its robust design reduces the need for frequent maintenance, leading to cost savings and increased uptime. The connector also enhances safety and reliability, crucial factors in commercial truck operations.

Installation Considerations

When installing the Cummins 3002075 Female Connector, it is important to follow guidelines to ensure a proper and secure connection. This includes using the necessary tools, preparing the connection points, and ensuring correct alignment. Proper installation is vital to the connector’s performance and the overall integrity of the truck’s systems.

Troubleshooting and Maintenance

Common issues with the Cummins 3002075 Female Connector may include loose connections or corrosion. Diagnostic steps involve inspecting the connector for signs of wear or damage and ensuring it is properly aligned and secured. Regular maintenance, such as cleaning and tightening connections, can help prevent issues and ensure optimal performance.

Compatibility and Usage

The Cummins 3002075 Female Connector is compatible with a range of systems and truck models. It is commonly used in applications where reliable electrical or fluid connections are required. Specific installation and operational considerations may vary depending on the truck model and system requirements.

Safety Precautions

When working with the Cummins 3002075 Female Connector, observing safety measures is crucial. This includes adhering to electrical safety protocols, handling the connector with care, and following system shutdown procedures during maintenance to prevent accidents and ensure personal safety.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and components like the 3002075 Female Connector, Cummins has established a reputation for reliability and performance in demanding applications.

Cummins Female Connector 3002075 Compatibility

The Cummins Female Connector 3002075 is a versatile component designed to fit a variety of Cummins engines, ensuring seamless integration and reliable performance. This part is engineered to meet the specific needs of the following engine models:

K19 Series

- K19

- KTA19GC CM558

The K19 series engines benefit from the 3002075 connector due to its robust design, which provides a secure connection for various fluid lines, enhancing the engine’s operational efficiency.

NH/NT Series

- NH/NT 855

In the NH/NT 855 engine, the 3002075 connector is essential for maintaining the integrity of hydraulic and fuel systems. Its precise fit ensures minimal leakage and optimal performance.

QSK19 Series

- QSK19 CM2350 K114

- QSK19 CM500

- QSK19 CM850 MCRS

The QSK19 series engines, including the CM2350 K114, CM500, and CM850 MCRS, also utilize the 3002075 connector. This part is critical for the hydraulic systems in these engines, providing a dependable connection that supports the high demands of industrial applications.

The 3002075 connector’s compatibility across these diverse engine models underscores its importance in maintaining the functionality and reliability of Cummins engines.

Role of Part 3002075 Female Connector in Engine Systems

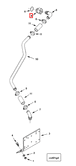

The part 3002075 Female Connector is integral to the efficient operation of various engine systems, facilitating the secure and reliable connection of fluid lines. Its application spans across multiple components, ensuring seamless fluid transfer and system functionality.

Accessories

In accessory systems, the Female Connector is used to link hydraulic lines, ensuring that hydraulic starting aids operate without leaks or disconnections. This is vital for systems that rely on precise hydraulic pressure for starting mechanisms.

Coolant Systems

For coolant heater starting systems, the Female Connector plays a significant role in the coolant heater plumbing. It ensures that the coolant heater and its mounting components are properly connected, allowing for efficient heat transfer to the engine during cold starts. This connection is also essential for the coolant heater starting aid, enhancing engine warm-up times and overall performance.

Oil Cooling Systems

In engine oil cooler and torque converter oil cooler applications, the Female Connector is used to join oil lines. This ensures that oil is effectively circulated through the coolers, maintaining optimal oil temperature and viscosity for engine lubrication and performance. The connection to the engine cast cooler is similarly important, as it helps in dissipating excess heat from the engine oil.

Turbocharger Systems

For turbocharger applications, the Female Connector is utilized in the plumbing of oil lines to the turbocharger. This ensures that the turbocharger receives the necessary lubrication and cooling, enhancing its efficiency and longevity. The connection to the oiler cooler is also critical, as it helps in maintaining the oil temperature within the desired range for turbocharger operation.

Water Cooling Systems

In water cooling systems, the Female Connector is employed in the water inlet and water outlet tubes. This ensures that water flows efficiently through the water heater tube and other cooling components, aiding in the regulation of engine temperature. The secure connection provided by the Female Connector is essential for preventing leaks and ensuring consistent cooling performance.

Starting Aid Systems

For systems incorporating a starting aid, the Female Connector is used in the plumbing to ensure that the starting aid fluid is delivered reliably to the engine. This is particularly important for systems that use a coolant heater starting aid, as it ensures that the engine receives the necessary heat for smooth starts in cold conditions.

Overall, the part 3002075 Female Connector is a versatile component that enhances the reliability and efficiency of various engine systems by providing secure and leak-free connections for fluid lines.

Conclusion

The Cummins 3002075 Female Connector is a critical component in the operation of commercial truck systems, ensuring reliable and efficient connections across various engine systems. Its robust design, compatibility with multiple engine models, and role in enhancing system performance make it an essential part for maintaining the functionality and reliability of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.