Introduction

The Cummins 3932301 Female Connector is a specialized component designed for use in commercial truck operations. This connector plays a role in facilitating secure and reliable connections within the truck’s electrical or fluid systems. Its significance lies in ensuring the efficient and safe operation of various truck systems, contributing to overall vehicle performance and reliability 2.

Basic Concepts of Female Connectors

Female connectors are components used in both electrical and fluid systems to establish connections between different parts of a system. They typically feature a receptacle design that allows for the insertion of a corresponding male connector. In automotive and industrial settings, these connectors are vital for transmitting power, signals, or fluids between components, ensuring seamless operation and integration of various systems 1.

Purpose of the 3932301 Female Connector

The Cummins 3932301 Female Connector is designed to play a specific role within a truck’s electrical or fluid system. It provides a secure connection point for cables, wires, or hoses, ensuring that the transmission of electricity or fluids is consistent and reliable. This connector is integral to maintaining the functionality of the truck’s systems, supporting everything from engine performance to auxiliary functions 2.

Key Features

The Cummins 3932301 Female Connector is characterized by several key features that enhance its performance and durability. These include a robust material composition, typically involving high-grade plastics or metals that can withstand harsh environmental conditions. The design elements of the connector, such as its locking mechanism and sealing properties, are tailored to provide a secure fit and prevent leaks or disconnections. Additionally, any unique characteristics, such as corrosion resistance or temperature tolerance, further contribute to its reliability 3.

Benefits

The Cummins 3932301 Female Connector offers several advantages. It contributes to improved system reliability by ensuring secure and consistent connections. The design of the connector also facilitates ease of installation, reducing the time and effort required for maintenance or repairs. Furthermore, its durable construction and resistance to environmental factors provide long-term benefits, minimizing the need for frequent replacements 2.

Installation Process

Proper installation of the Cummins 3932301 Female Connector involves several steps to ensure a secure and functional connection. Begin by preparing the connection point, ensuring it is clean and free from debris. Align the connector with the corresponding male component and insert it firmly, engaging any locking mechanisms. Verify the connection by checking for stability and proper alignment. It is important to follow manufacturer guidelines and best practices to avoid common pitfalls such as improper alignment or insufficient locking, which can lead to connection failures 1.

Troubleshooting Common Issues

Frequent problems with female connectors can include loose connections, corrosion, or damage to the connector itself. For the Cummins 3932301, diagnostic steps may involve inspecting the connection for signs of wear or corrosion, ensuring the locking mechanism is engaged, and checking for proper alignment. Repair methods may include cleaning the connector, tightening the connection, or replacing damaged components to restore functionality 3.

Maintenance Tips

Routine maintenance practices for the Cummins 3932301 Female Connector include regular inspection for signs of wear, corrosion, or damage. Cleaning the connector and its surrounding area can prevent buildup that may interfere with the connection. Additionally, verifying the integrity of the locking mechanism and ensuring all connections are secure can help maintain optimal performance and longevity of the connector 2.

Safety Considerations

When working with the Cummins 3932301 Female Connector, it is important to observe safety protocols to ensure personal safety and system integrity. This includes adhering to electrical safety practices, such as ensuring the system is de-energized before performing any maintenance or repairs. Additionally, following proper handling procedures and using appropriate tools can help prevent damage to the connector and ensure a secure installation 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations 2.

Cummins Female Connector 3932301 Compatibility

The Cummins Female Connector part number 3932301 is designed to fit a variety of Cummins engines, ensuring seamless integration and reliable performance. This part is crucial for maintaining the integrity of the fuel and fluid systems in these engines.

Compatible Engines

4B3.9, 6B5.9, 6C8.3, B3.3, B3.9 G, B4.5, B5.9 G, B5.9 GAS PLUS CM556, C GAS PLUS CM556, C8.3 G, G5.9, G8.3, GTA8.3 CM558

These engines, primarily used in various industrial and commercial applications, benefit from the robust design of the 3932301 connector. This part ensures that the fuel and fluid lines are securely connected, reducing the risk of leaks and ensuring optimal engine performance.

ISB CM2150, ISB CM550, ISB6.7 CM2250, ISB6.7 CM2350 B101, ISBE CM800, ISBE4 CM850

The ISB series engines, known for their power and efficiency, also utilize the 3932301 connector. This part is engineered to withstand the high pressures and demands of these engines, providing a reliable connection that enhances the overall performance and longevity of the engine.

ISC CM2150, ISC CM554, ISC8.3 CM2250, ISL CM2150, ISL9 CM2150 SN, ISL9 CM2250

The ISC and ISL series engines, often found in heavy-duty applications, also require the 3932301 connector for their fuel and fluid systems. This part ensures that these engines operate smoothly and efficiently, with secure connections that prevent leaks and maintain system integrity.

By ensuring compatibility with such a wide range of engines, the Cummins Female Connector 3932301 provides a versatile solution for maintaining and repairing various Cummins engine models 2.

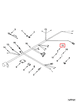

Role of Part 3932301 Female Connector in Engine Systems

The part 3932301 Female Connector is integral to the seamless operation of various engine systems, facilitating the connection between different components to ensure efficient and reliable performance.

In the electrical system, the Female Connector is used to link the harness wiring to the module engine control, allowing for the transmission of electrical signals that are vital for engine operation and monitoring. It also plays a part in connecting the sensor oil pressure to the system engine monitoring, ensuring that oil pressure data is accurately relayed to the engine control module for real-time adjustments.

Within the fuel system, the Female Connector is employed to join the fuel block connection to the filter fuel, ensuring a secure and leak-free pathway for fuel to travel from the fuel filter to the engine. This connection is also seen at the fuel filter location, where it interfaces with the filter support to maintain the structural integrity of the fuel filtration system.

For the air system, the Female Connector is utilized in the air governor and air governor mounting to connect the air compressor and governor air components. This ensures that the air pressure is regulated effectively, contributing to the overall performance of the compressor system.

In terms of engine monitoring and instrumentation, the Female Connector is used to link the panel engine instrument to various sensors and switches, such as the switch coolant pressure and switch oil pressure. This allows for the accurate monitoring of engine conditions and the prompt detection of any anomalies.

Lastly, in the valve system, the Female Connector is part of the valve fuel shutoff mechanism, ensuring that the fuel supply can be safely and efficiently controlled as needed.

Overall, the Female Connector is a versatile component that enhances the functionality and reliability of engine systems by providing secure and efficient connections between critical components 3.

Conclusion

The Cummins 3932301 Female Connector is a critical component in the operation of commercial truck engines, ensuring secure and reliable connections within various systems. Its robust design, compatibility with a wide range of Cummins engines, and role in enhancing engine performance make it an essential part for maintaining the integrity and efficiency of truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.