68138

Male Connector

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 68138 Male Connector is a specialized component designed for use in commercial trucks. It plays a role in ensuring the efficient operation of various systems within these vehicles. Cummins, a well-established manufacturer in the automotive industry, produces this connector as part of its extensive range of high-quality parts aimed at enhancing the performance and reliability of commercial trucks 1.

Basic Concepts of Male Connectors

Male connectors are integral components in both electrical and fluid systems of vehicles. They facilitate the transfer of electricity or fluids between different parts of a system by providing a secure and reliable connection point. In the automotive industry, these connectors are used in a variety of applications, including wiring harnesses, fuel systems, and hydraulic circuits, ensuring that systems operate smoothly and efficiently 2.

Purpose of the 68138 Male Connector

This Cummins part is specifically designed to play a role in the electrical systems or fluid transfer mechanisms of commercial trucks. It ensures a secure connection between components, allowing for the efficient transmission of electricity or fluids. This connector is particularly important in systems where reliability and durability are paramount, such as in the demanding environments of commercial trucking 3.

Key Features

The 68138 boasts several key features that enhance its functionality and durability. Its design incorporates high-quality materials that are resistant to wear and corrosion, ensuring long-lasting performance. The connection type is engineered for a secure fit, minimizing the risk of disconnections or leaks. Additionally, the connector may feature unique attributes such as weather-resistant coatings or enhanced locking mechanisms to further improve its reliability in harsh conditions 4.

Benefits

The advantages provided by the 68138 include improved system reliability, ease of installation, and compatibility with a wide range of systems. Its design allows for quick and straightforward installation, reducing downtime for commercial trucks. Furthermore, the connector’s compatibility with various systems ensures that it can be used in a broad range of applications, enhancing its versatility 5.

Installation and Usage

Proper installation of the 68138 is crucial for ensuring its optimal performance. Guidelines for installation include verifying that the connector is compatible with the system it will be used in and ensuring that all connections are secure and tight. Special considerations may include checking for any obstructions that could interfere with the connector’s operation and ensuring that the system is de-energized before beginning installation to prevent electrical hazards 6.

Troubleshooting and Maintenance

Common issues with the 68138 may include loose connections or corrosion. Troubleshooting these problems involves inspecting the connector for signs of wear or damage and ensuring that all connections are secure. Maintenance tips to ensure longevity and optimal performance include regular inspection for signs of corrosion or wear, cleaning the connector as necessary, and replacing it if any damage is detected. Safe removal and replacement procedures should be followed to prevent injury or damage to the system 7.

Safety Considerations

When working with the 68138, it is important to observe several safety guidelines and precautions. Electrical safety is paramount, and it is crucial to ensure that the system is de-energized before beginning any work on the connector. Proper handling of the connector is also important to prevent damage or injury. Compliance with industry standards and regulations is necessary to ensure safe and effective use of the connector 8.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance parts, Cummins has established itself as a trusted name in the automotive sector. The company’s extensive product range includes engines, powertrains, and components designed to enhance the efficiency and reliability of commercial vehicles. Cummins’ reputation for quality and innovation is built on its dedication to meeting the needs of its customers and advancing the technology of the automotive industry 9.

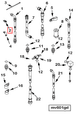

Cummins Engine Compatibility with Male Connector Part 68138

The Cummins Male Connector part 68138 is designed to fit seamlessly with a variety of Cummins engine models. This part is integral for ensuring proper fluid flow and system integrity across different engine configurations.

6 Series Engines

- 6B5.9

- 6C8.3

- 6C8.3 G

These engines, part of the 6 Series, are known for their robust performance and reliability. The Male Connector part 68138 is specifically engineered to fit these models, ensuring a secure connection that can withstand the rigors of heavy-duty operations.

B5.9 Series Engines

- B5.9 G

- B5.9 GAS PLUS CM556

The B5.9 series engines, including the B5.9 G and B5.9 GAS PLUS CM556, benefit from the precision fit of the Male Connector part 68138. This part is designed to integrate smoothly with the engine’s fluid systems, providing a reliable connection that enhances overall engine performance.

C Series Engines

- C GAS PLUS CM556

- C8.3 G

- L GAS PLUS CM556

The C Series engines, such as the C GAS PLUS CM556, C8.3 G, and L GAS PLUS CM556, are equipped with the Male Connector part 68138 to ensure optimal fluid management. This connector is designed to fit these engines perfectly, facilitating efficient fluid flow and maintaining system integrity.

ISB and ISC Series Engines

- ISB CM550

- ISC CM554

- ISC CM850

- ISX CM570

The ISB and ISC series engines, including the ISB CM550, ISC CM554, ISC CM850, and ISX CM570, are compatible with the Male Connector part 68138. This part is designed to fit these engines, ensuring a secure and reliable connection that supports the engine’s fluid systems.

ISL Series Engines

- ISL CM554

- ISL9 CM2150 SN

The ISL series engines, such as the ISL CM554 and ISL9 CM2150 SN, are designed to work with the Male Connector part 68138. This connector ensures a precise fit, facilitating efficient fluid flow and maintaining the integrity of the engine’s systems.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM11 CM876 SN

The ISM series engines, including the ISM CM570, ISM CM570/870, and ISM11 CM876 SN, are compatible with the Male Connector part 68138. This part is designed to fit these engines, ensuring a secure and reliable connection that supports the engine’s fluid systems.

K Series Engines

- K19

- K38

- K50

The K Series engines, such as the K19, K38, and K50, are designed to work with the Male Connector part 68138. This connector ensures a precise fit, facilitating efficient fluid flow and maintaining the integrity of the engine’s systems.

L Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The L Series engines, including the L10 CELECT, L10 GAS, and L10 MECHANICAL, are compatible with the Male Connector part 68138. This part is designed to fit these engines, ensuring a secure and reliable connection that supports the engine’s fluid systems.

M11 Series Engines

- M11 CELECT

The M11 series engine, such as the M11 CELECT, is designed to work with the Male Connector part 68138. This connector ensures a precise fit, facilitating efficient fluid flow and maintaining the integrity of the engine’s systems.

Role of Part 68138 Male Connector in Engine Systems

The Part 68138 Male Connector is integral to the efficient operation of various engine systems. It facilitates secure and reliable connections between components, ensuring optimal performance and safety.

Air Starter Accessories and Air Starting Accessories

In air starter systems, the Male Connector ensures a tight seal between the air starter and its accessories. This prevents air leaks, which could lead to inefficient starting and potential damage to the starter.

Alternator Mounting

When mounting an alternator, the Male Connector is used to link the alternator to its power source and control systems. This ensures a stable electrical connection, which is vital for consistent power output and reliable engine operation.

Bypass Valve Actuator

For the Bypass Valve Actuator, the Male Connector plays a role in connecting the actuator to the control system. This connection is essential for precise valve operation, which affects engine performance and emissions.

Camshaft

In camshaft systems, the Male Connector is used to link sensors and control units to the camshaft. This ensures accurate data transmission for timing and performance adjustments.

Corrosion Resistor Bracket

The Male Connector is employed in corrosion resistor brackets to connect resistive elements to the engine’s electrical system. This helps in monitoring and mitigating corrosion, prolonging the lifespan of engine components.

Engine Monitoring

For engine monitoring systems, the Male Connector is critical in linking various sensors to the central monitoring unit. This ensures real-time data collection and analysis, aiding in proactive maintenance and performance optimization.

Exhaust Cooler Leak Test Kit

In exhaust cooler systems, the Male Connector is used during leak testing to ensure all connections are secure and leak-free. This is important for maintaining the integrity of the exhaust system and ensuring efficient cooling.

Fan Mounting Hub

The Male Connector in fan mounting hubs ensures a reliable connection between the fan and its power source. This is essential for effective cooling of the engine, preventing overheating.

Flexible Hose Kit

In flexible hose kits, the Male Connector is used to create secure joints between hose sections. This prevents leaks and ensures the smooth flow of fluids, whether it be fuel, coolant, or air.

Flow Meter

For flow meters, the Male Connector is used to link the meter to the fluid system. This ensures accurate measurement of fluid flow, which is important for engine performance and efficiency.

Fuel Bypass Hose and Fuel Bypass Mounting

In fuel bypass systems, the Male Connector ensures a secure connection between the hose and the mounting points. This is vital for maintaining the integrity of the fuel system and ensuring consistent fuel delivery.

Fuel Tube Mounting

The Male Connector in fuel tube mounting systems ensures a tight and secure connection between fuel tubes and their mounting points. This prevents fuel leaks and ensures safe and efficient fuel delivery.

Fuel, Tubing, Housing

For fuel systems, the Male Connector is used to link fuel tubing to the housing. This ensures a leak-free connection, which is essential for safe and efficient fuel management.

Flywheel Repto

In flywheel replacement systems, the Male Connector is used to link the flywheel to its control and power systems. This ensures smooth operation and reliable performance.

Instrument Pan Accessory and Instrument Panel Dummy

For instrument panel systems, the Male Connector is used to link accessories and dummy units to the main panel. This ensures accurate data display and system functionality.

Lucifer Mounting Valve

In lucifer mounting valve systems, the Male Connector ensures a secure connection between the valve and its control system. This is important for precise valve operation and system safety.

Manifold Press Mounting Tube

For manifold pressure systems, the Male Connector is used to link the mounting tube to the pressure sensor. This ensures accurate pressure readings and system performance.

Mtg. Air Governor

In air governor systems, the Male Connector is used to link the governor to its control system. This ensures precise air management and engine performance.

Performance and Pressure Sender

For performance and pressure sender systems, the Male Connector ensures a reliable connection between the sender and the engine’s control unit. This is vital for accurate data transmission and system performance.

Thermostat Housing Plumbing

In thermostat housing systems, the Male Connector is used to link the housing to the plumbing. This ensures a secure and leak-free connection, which is important for maintaining engine temperature and performance.

Vent Engine

Finally, in vent engine systems, the Male Connector is used to link the vent to the engine’s control system. This ensures proper ventilation and pressure management within the engine compartment.

Conclusion

The Cummins 68138 Male Connector is a critical component in the operation of commercial truck engine systems. Its design and features ensure reliable and efficient connections, contributing to the overall performance and safety of the vehicle. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this connector.

-

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Cummins Inc. General Information. Bulletin Number 4915536, Owners Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4915536, Owners Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4915536, Owners Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4915536, Owners Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4915536, Owners Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.