This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3420545 Control Linkage Lever is a component manufactured by Cummins, a prominent name in the commercial truck industry. This part is integral to the operation of commercial trucks, facilitating the mechanical linkage between various systems within the vehicle. Cummins, known for its robust and reliable truck components, ensures that this control linkage lever is designed to meet the demanding requirements of heavy-duty applications.

Basic Concepts of Control Linkage Levers

A Control Linkage Lever is a mechanical component that transmits motion from one part of a system to another. In the context of a truck’s mechanical system, it serves as a connector that allows for the precise movement and positioning of other components. The operation of a control linkage lever is based on mechanical principles such as leverage and force transmission. It interacts with other parts of the truck’s system to ensure that movements are synchronized and controlled, contributing to the overall efficiency and performance of the vehicle 1.

Role of the 3420545 Control Linkage Lever in Truck Operation

The 3420545 Control Linkage Lever plays a specific role in the operation of a truck by connecting and coordinating the movements between different mechanical systems. It ensures that the truck’s components operate in harmony, which is vital for the vehicle’s functionality and performance. This lever is part of the system that allows for the adjustment and control of various truck functions, directly impacting how the truck responds to driver inputs and environmental conditions 2.

Key Features of the 3420545 Control Linkage Lever

The 3420545 Control Linkage Lever is characterized by several key features that enhance its performance and durability. These include a robust design that can withstand the rigors of heavy-duty use, the use of high-quality materials that resist wear and corrosion, and precise engineering that ensures smooth operation. Additionally, the lever may feature unique design elements that improve its integration with other truck components, making it a standout part in its category 3.

Benefits of Using the 3420545 Control Linkage Lever

Utilizing the 3420545 Control Linkage Lever offers several benefits. These include improved performance due to its precise engineering, enhanced durability thanks to the use of high-quality materials, and ease of maintenance owing to its design. The lever’s ability to integrate seamlessly with a truck’s system also contributes to more efficient operation and reduced downtime, making it a valuable component for truck operators 4.

Installation and Integration

When installing the 3420545 Control Linkage Lever, it is important to follow guidelines that ensure proper integration into the truck’s system. Best practices include careful alignment with other components, secure fastening, and verification of movement and operation post-installation. Avoiding common pitfalls such as incorrect alignment or insufficient tightening can prevent issues down the line, ensuring the lever functions as intended.

Troubleshooting Common Issues

Common issues with the 3420545 Control Linkage Lever may include misalignment, wear, or damage. Troubleshooting these problems involves a systematic approach to diagnosis, starting with a visual inspection for signs of wear or damage, followed by checks for proper alignment and movement. Basic repairs or adjustments may be necessary to restore the lever’s functionality, ensuring the truck operates smoothly.

Maintenance Tips

Regular maintenance of the 3420545 Control Linkage Lever is key to ensuring its longevity and optimal performance. This includes cleaning the lever to remove dirt and debris, lubricating moving parts to reduce friction and wear, and performing regular inspections for signs of damage or wear. Adhering to these maintenance tips can help prevent issues and extend the life of the lever.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality components and engines. With a history of innovation and excellence, Cummins has established a reputation for reliability and performance. The company’s commitment to quality and customer satisfaction makes it a trusted choice for truck components, including the 3420545 Control Linkage Lever.

Cummins Control Linkage Lever 3420545 Compatibility

The Cummins Control Linkage Lever part number 3420545 is designed to integrate seamlessly with a range of Cummins engines, ensuring precise control and efficient operation. This part is compatible with the following engines:

- QSW/QSV82

- QSW73

These engines are known for their robust performance and reliability, making them suitable for a variety of applications. The Control Linkage Lever is a critical component that facilitates the smooth transmission of power and control signals within the engine system. Its design ensures that it fits perfectly with the specified engines, maintaining the integrity and functionality of the engine’s control mechanisms.

Integration of Control Linkage Lever (Part 3420545) in Engine Systems

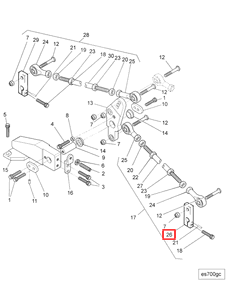

The Control Linkage Lever (Part 3420545) is an integral component in the orchestration of engine operations, specifically within the governor assembly. Its primary function is to facilitate the mechanical connection between various engine components, ensuring precise control and regulation of engine speed and performance.

Interaction with Governor Assembly Linkage

The Control Linkage Lever interfaces directly with the Governor Assembly Linkage. This connection allows for the transmission of motion from the Governor Assembly Shaft to other parts of the governor system. The lever’s design enables it to modulate the force and direction of this motion, which is essential for maintaining the desired engine speed under varying load conditions.

Role in Governor Assembly Shaft Operation

When the Governor Assembly Shaft rotates in response to changes in engine speed, the Control Linkage Lever translates this rotational motion into linear motion. This conversion is vital for the accurate adjustment of the Throttle Shaft position, which in turn controls the airflow into the engine, affecting its power output.

Coordination with Governor Counter Assembly Linkage

The lever also plays a part in the operation of the Governor Counter Assembly Linkage. By providing a stable and adjustable connection point, it allows the counter assembly to react to changes in engine load and speed, ensuring that the engine maintains a consistent performance level.

Governor Linkage and Overall System Harmony

In conjunction with the Governor Linkage, the Control Linkage Lever ensures that all components within the governor system work in unison. This harmony is necessary for the fine-tuning of engine operations, allowing for smooth acceleration, deceleration, and stable idling.

Influence on Linkage and Governor Control

The lever’s influence extends to the broader Linkage system and Governor Control mechanisms. It acts as a pivotal point that can be adjusted to fine-tune the engine’s response to various driving conditions, contributing to the overall efficiency and responsiveness of the engine.

Impact on Throttle Shaft

Finally, the Control Linkage Lever’s interaction with the Throttle Shaft is noteworthy. By precisely controlling the throttle’s opening and closing, the lever directly impacts the engine’s fuel intake and, consequently, its power output. This makes the lever a key player in the engine’s ability to deliver the right amount of power at the right time.

Conclusion

The 3420545 Control Linkage Lever is a critical component in the operation of commercial trucks, ensuring the precise control and regulation of engine speed and performance. Its robust design, high-quality materials, and precise engineering make it a valuable asset for truck operators, contributing to improved performance, enhanced durability, and ease of maintenance. Proper installation, regular maintenance, and troubleshooting common issues are essential for maximizing the benefits of this Cummins part.

-

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.