This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Corrosion Resistor 3318201, manufactured by Cummins, is a component designed to enhance the durability and reliability of commercial trucks. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation. This part is significant in commercial truck operations as it helps protect critical components from the detrimental effects of corrosion, thereby contributing to the longevity and performance of the vehicle 1.

Basic Concepts of Corrosion Resistors

Corrosion resistors are devices designed to protect metal components from corrosion, a natural process that can significantly degrade the performance and lifespan of metal parts. These resistors function by creating a barrier between the metal and the corrosive elements, such as moisture and chemicals. This barrier helps prevent the oxidation process that leads to rust and other forms of corrosion 2. The importance of corrosion resistors in protecting metal components cannot be overstated, as they play a vital role in maintaining the structural integrity and functionality of various systems within a vehicle.

Purpose of the 3318201 Corrosion Resistor

The 3318201 Corrosion Resistor is specifically designed to protect certain components within a truck’s system from corrosion. Its placement is strategic, targeting areas most susceptible to corrosion. By doing so, it helps maintain the efficiency and reliability of the truck’s operations. The resistor works by forming a protective layer over the metal surfaces, shielding them from environmental factors that contribute to corrosion.

Key Features

The 3318201 Corrosion Resistor boasts several key features that enhance its performance. It is composed of materials specifically chosen for their resistance to corrosion and durability. The design elements of the resistor ensure it can withstand the harsh conditions often encountered in commercial truck operations. Additionally, it may include unique characteristics such as a specially formulated coating that provides an extra layer of protection against corrosive elements.

Benefits of Using the 3318201 Corrosion Resistor

Incorporating the 3318201 Corrosion Resistor into a truck’s system offers several advantages. It contributes to improved durability of the protected components, extending their lifespan and reducing the need for frequent replacements. This, in turn, can lead to cost savings over time. Furthermore, by protecting critical components from corrosion, the resistor helps maintain the overall performance of the truck, ensuring it operates efficiently and reliably 3.

Installation Process

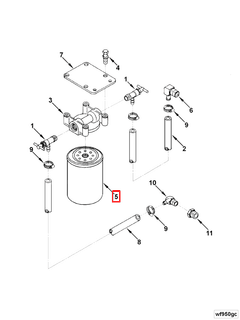

Proper installation of the 3318201 Corrosion Resistor is crucial for its effective functioning. The process involves several steps, including preparing the area where the resistor will be installed, ensuring the surface is clean and free from existing corrosion. The necessary tools for installation should be gathered beforehand. Following the manufacturer’s guidelines for installation is recommended to ensure the resistor is correctly positioned and secured. Best practices include checking the resistor’s placement and connection to ensure it is properly integrated into the truck’s system.

Maintenance and Care

To ensure the optimal performance of the 3318201 Corrosion Resistor, regular maintenance and care are recommended. This includes inspecting the resistor at regular intervals for any signs of damage or wear. Cleaning procedures should be followed to remove any dirt or debris that may accumulate on the resistor, ensuring it continues to provide effective protection. Specific care instructions provided by the manufacturer should be adhered to, including any recommended cleaning agents or methods.

Troubleshooting Common Issues

Common issues that may arise with the 3318201 Corrosion Resistor can often be addressed through troubleshooting. Identifying problems early can prevent more significant issues from developing. Suggested troubleshooting steps may include checking the resistor for physical damage, ensuring it is properly installed, and verifying that it is functioning as intended. Solutions to common problems can range from simple adjustments to replacement of the resistor if necessary.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and other components for commercial vehicles. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to advancing technology and improving the efficiency and performance of its products is evident in its extensive product range and the trust it has earned from customers worldwide.

Compatibility with Engine Models

The 3318201 Corrosion Resistor is designed to enhance the durability and longevity of specific engine models by providing protection against corrosion. This part is integral to maintaining the integrity of the engine’s components, ensuring optimal performance and reducing the risk of costly repairs.

Compatibility with 6B5.9 and 6C8.3 Engines

The 6B5.9 and 6C8.3 engines benefit significantly from the installation of the 3318201 Corrosion Resistor. These engines, known for their robust design and reliability, are often used in heavy-duty applications where exposure to harsh environmental conditions is common. The corrosion resistor helps to shield critical engine parts from the damaging effects of moisture, salt, and other corrosive agents, thereby extending the lifespan of the engine and maintaining its performance.

Compatibility with C8.3 G Engine

The C8.3 G engine also integrates seamlessly with the 3318201 Corrosion Resistor. This engine model is designed for high-performance applications, and the addition of the corrosion resistor ensures that it can withstand the rigors of demanding environments. By preventing corrosion, the 3318201 part helps to preserve the engine’s efficiency and reliability, making it a valuable component for users who rely on their engines in challenging conditions.

Grouping of Engine Models

The 6B5.9, 6C8.3, and C8.3 G engines share a common need for corrosion protection, making the 3318201 Corrosion Resistor a versatile and essential part for these models. By grouping these engines together, it becomes clear that the corrosion resistor is a critical component for maintaining the health and performance of these engines, regardless of their specific application or environment.

Role of Part 3318201 Corrosion Resistor in Engine Systems

In the context of engine systems, the 3318201 Corrosion Resistor is integral to maintaining the longevity and efficiency of various components. When integrated into an Engine Overhaul Kit, this corrosion resistor significantly enhances the durability of the engine by preventing rust and corrosion, which are common issues in high-stress environments.

The resistor works in conjunction with other components to ensure that the engine operates smoothly over extended periods. For instance, in systems where metal parts are exposed to moisture or chemical agents, the corrosion resistor provides a protective layer that mitigates the adverse effects of these elements.

Additionally, the incorporation of this resistor in the overhaul kit means that during maintenance or repair processes, the likelihood of future corrosion-related issues is substantially reduced. This not only saves time during subsequent repairs but also reduces the overall cost of maintenance by prolonging the lifespan of the engine components.

Conclusion

In summary, the 3318201 Corrosion Resistor plays a significant role in preserving the integrity of engine systems, ensuring that they remain efficient and reliable over time. Its strategic placement, key features, and benefits make it a valuable component for maintaining the performance and longevity of commercial trucks.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.