This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

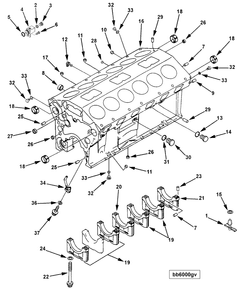

The Cummins 2897051 Cylinder Block is a critical component in heavy-duty truck engines, contributing significantly to engine performance and durability. This part is designed to withstand the rigorous demands of heavy-duty applications, ensuring reliable operation and efficiency.

Basic Concepts of Cylinder Blocks

A cylinder block, or engine block, serves as the structural foundation of an engine. It houses the cylinders, where combustion occurs, and provides mounting points for other critical components such as the crankshaft, pistons, and cylinder head. The block plays a role in maintaining the engine’s structural integrity and facilitates the circulation of coolant to regulate temperature 3.

Purpose of the Cummins 2897051 Cylinder Block

The Cummins 2897051 Cylinder Block is engineered to enhance the operation of truck engines. It contributes to engine efficiency by providing a robust structure that supports the combustion process. The block’s design allows for optimal power output and efficient heat dissipation, which are essential for maintaining engine performance under heavy loads 4.

Key Features

The Cummins 2897051 Cylinder Block boasts several key features that enhance its performance and reliability. It is constructed from high-quality cast iron, known for its durability and ability to withstand high temperatures and pressures. The block features precision-machined cylinder bores to ensure smooth piston operation and reduce friction. Additionally, it includes integrated cooling passages that aid in maintaining optimal operating temperatures 1.

Benefits

The Cummins 2897051 Cylinder Block offers numerous benefits, including improved engine performance and durability. Its robust construction and precise engineering contribute to enhanced power output and reliability. The block’s efficient cooling system helps prevent overheating, ensuring consistent performance even under demanding conditions. Compared to other cylinder blocks, the Cummins 2897051 provides superior durability and performance, making it a preferred choice for heavy-duty applications 2.

Troubleshooting and Maintenance

To ensure optimal performance and longevity of the Cummins 2897051 Cylinder Block, regular maintenance is recommended. Common issues may include wear on cylinder bores, coolant leaks, and warped surfaces. Routine inspections and maintenance practices, such as checking coolant levels, monitoring engine temperature, and addressing any signs of wear or damage promptly, can help prevent major issues and extend the block’s service life 3.

Manufacturing and Quality Control

Cummins employs rigorous manufacturing processes and quality control measures to ensure the reliability and performance of the 2897051 Cylinder Block. The block undergoes precision casting and machining to meet stringent tolerances. Quality control inspections are conducted at various stages of production to verify dimensional accuracy, material integrity, and overall performance. These measures help ensure that each cylinder block meets Cummins’ high standards for quality and reliability 4.

Integration with Other Engine Components

The Cummins 2897051 Cylinder Block integrates seamlessly with other engine components to form a cohesive and efficient engine system. It provides mounting points for the crankshaft, which converts linear piston motion into rotational force. The block also houses the pistons, which move up and down within the cylinders during combustion. Additionally, it mates with the cylinder head, which covers the cylinders and contains the valves and fuel injectors. This integration ensures smooth operation and optimal performance of the engine 1.

Historical Development

The development of cylinder blocks has evolved over time, with advancements in design and materials leading to more efficient and durable engine components. Early cylinder blocks were often made from cast iron, which provided good strength and heat dissipation properties. Modern cylinder blocks, like the Cummins 2897051, benefit from improved manufacturing techniques and materials, resulting in enhanced performance and reliability 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a reputation for innovation and quality, Cummins has been a trusted name in the industry for over a century. The company is committed to delivering reliable and efficient engine components that meet the demanding needs of various applications, including heavy-duty trucks 3.

Cummins Cylinder Block 2897051 Compatibility

The Cummins Cylinder Block part number 2897051 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is engineered to meet the specific requirements of the engines it supports, providing a robust foundation for engine operation.

QST30 Series

- QST30 CM2350 T101

- QST30 CM552

The Cummins Cylinder Block 2897051 is compatible with both the QST30 CM2350 T101 and QST30 CM552 engines. This compatibility ensures that the cylinder block integrates smoothly with the engine’s design, maintaining the structural integrity and operational efficiency of the engine. The part is crafted to fit precisely, facilitating easy installation and reducing the risk of misalignment or improper fitment.

This compatibility underscores Cummins’ commitment to providing high-quality, reliable parts that enhance the performance and longevity of their engines 4.

Role of Part 2897051 Cylinder Block in Engine Systems

The part 2897051 Cylinder Block is integral to the functionality of an engine system, serving as the structural core that houses several key components.

Integration with Engine Components

-

Cylinders: The Cylinder Block contains the cylinders, which are the chambers where the combustion of fuel occurs. Each cylinder is bored into the block and is designed to withstand high pressures and temperatures generated during combustion 1.

-

Pistons and Connecting Rods: Within the cylinders, pistons move up and down in response to combustion. These pistons are connected to the crankshaft via connecting rods, which are also supported by the Cylinder Block. This arrangement allows the linear motion of the pistons to be converted into rotational motion 2.

-

Crankshaft: The crankshaft is supported by main bearings housed within the Cylinder Block. As the pistons move, they drive the crankshaft, which in turn drives the rest of the engine components through the flywheel 3.

-

Coolant Passages: The Cylinder Block includes passages for coolant circulation. These passages help manage the engine’s temperature by allowing coolant to absorb heat from the cylinders and other components, then transferring it to the radiator 4.

-

Oil Galleries: Integrated into the Cylinder Block are oil galleries that distribute lubrication to moving parts such as the crankshaft, pistons, and valve train. Proper lubrication reduces friction and wear, ensuring longevity and efficiency of the engine 1.

-

Water Jacket: Surrounding the cylinders within the Cylinder Block is the water jacket, which contains coolant. This jacket helps in evenly distributing heat across the engine, preventing hotspots and ensuring consistent performance 2.

-

Main Bearing Caps: These caps are bolted to the Cylinder Block and provide additional support and stability to the crankshaft. They are critical for maintaining the alignment and balance of the crankshaft during operation 3.

-

Cylinder Head: The Cylinder Block interfaces with the cylinder head, which houses the valves and combustion chambers. The seal between the block and the head is vital for maintaining compression and preventing leaks 4.

Conclusion

In summary, the Cummins 2897051 Cylinder Block is the foundational element that supports and integrates various engine components, ensuring the engine operates smoothly and efficiently. Its robust construction, precise engineering, and compatibility with various engine models make it a reliable choice for heavy-duty applications.

-

Livesey, A. (2000). The Repair of Vehicle Bodies. Elevier.

↩ ↩ ↩ ↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ ↩ ↩ ↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ ↩ ↩ ↩ ↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ ↩ ↩ ↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.