This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

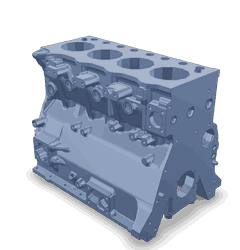

The Cummins 4941114 Cylinder Block is a vital component in heavy-duty truck engines, contributing significantly to efficient engine operation. This part is designed to withstand the demanding conditions of commercial trucking, ensuring reliable performance and durability 1.

Basic Concepts of a Cylinder Block

A cylinder block, or engine block, serves as the structural foundation of an engine. It houses the cylinders, where combustion occurs, and provides mounting points for other critical components such as the crankshaft, pistons, and cylinder heads. The cylinder block plays a role in maintaining the engine’s structural integrity and facilitates the flow of coolant and lubricants to various engine parts 2.

Purpose of the Cummins 4941114 Cylinder Block

This Cummins part is engineered to enhance the operation of truck engines. It contributes to engine performance by providing a robust framework that supports the combustion process and helps manage engine temperatures. Its design aids in achieving optimal engine efficiency and longevity, making it a key component in the powertrain of heavy-duty vehicles 3.

Key Features

The 4941114 boasts several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability under high stress and temperature conditions. The design incorporates advanced cooling channels and precise machining to improve thermal management and reduce the risk of warping. Additionally, the block features robust mounting points for critical engine components, contributing to overall engine stability and performance.

Benefits

This part offers numerous benefits that contribute to improved engine efficiency, durability, and reliability. Its advanced design helps maintain consistent engine temperatures, which can lead to more efficient combustion and reduced wear on engine components. The robust construction ensures that the block can withstand the rigors of heavy-duty use, providing long-term reliability. These benefits translate to better overall truck performance, including enhanced fuel efficiency and reduced maintenance requirements.

Installation Process

Installing this part requires careful attention to detail to ensure proper fit and function. The process involves preparing the engine bay, aligning the block with the crankshaft and other components, and securing it in place with the appropriate fasteners. It is important to follow manufacturer guidelines to ensure that all tolerances are met and that the block is installed level and square within the engine compartment. Additionally, proper sealing of coolant and oil passages is critical to prevent leaks and ensure efficient fluid flow.

Maintenance Tips

To ensure optimal performance and longevity of the 4941114, regular maintenance is recommended. This includes inspecting the block for signs of wear or damage, cleaning coolant and oil passages to prevent blockages, and applying the recommended lubricants to moving parts. Additionally, monitoring engine temperatures and fluid levels can help identify potential issues before they become serious problems. Following these maintenance practices can help extend the life of the cylinder block and maintain engine efficiency.

Troubleshooting Common Issues

Common issues with the 4941114 may include leaks, cracks, or performance problems. Troubleshooting these issues involves a systematic approach to identify the root cause. For leaks, inspecting gaskets and seals for wear or damage is a good starting point. Cracks may be detected through visual inspection or by using a dye penetrant inspection method. Performance issues could be related to improper installation, inadequate maintenance, or other engine component failures. Addressing these issues promptly can help maintain engine efficiency and prevent further damage.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a strong reputation in the industry for innovation and quality, Cummins has been a trusted name in engine manufacturing for over a century. The company is committed to advancing technology and providing reliable, high-performance engine components that meet the needs of various industries, including heavy-duty trucking.

Compatibility

The 4941114 is a critical component that fits seamlessly into various Cummins engines, ensuring robust performance and durability. This part is engineered to meet the stringent requirements of Cummins’ lineup, providing a reliable foundation for the engine’s operation.

QSB3.3 CM2150 Engines

The 4941114 is specifically designed to fit the QSB3.3 CM2150 engines. This engine model is known for its efficiency and power, making it a popular choice in various applications. The cylinder block part ensures that the engine operates smoothly, withstanding the rigors of continuous use.

Other Cummins Engines

While the primary focus here is on the QSB3.3 CM2150, it is important to note that the 4941114 is also compatible with other Cummins engine models. This versatility underscores the part’s robust design and its ability to integrate with different engine configurations, ensuring a consistent performance across the Cummins engine range.

Role of 4941114 Cylinder Block in Engine Systems

The 4941114 is a fundamental component in the assembly and operation of engine systems. It serves as the primary structural element, housing the cylinders where combustion occurs. The block is designed to integrate seamlessly with various other components to ensure efficient engine performance.

Integration with Engine Components

-

Cylinders and Pistons: The Cylinder Block contains the cylinders, which are bored into the block. Pistons move within these cylinders, driven by the combustion of fuel. The block’s design ensures precise alignment and smooth operation of the pistons.

-

Crankshaft: The Cylinder Block is bored to accommodate the crankshaft, which converts the linear motion of the pistons into rotational motion. The block’s main bearings support the crankshaft, allowing it to rotate with minimal friction.

-

Camshaft: In engines with an overhead camshaft (OHC) design, the Cylinder Block includes passages or mounts for the camshaft. This component controls the opening and closing of the valves, timed with the pistons’ movement.

-

Cooling System: The block features water jackets—channels through which coolant flows to manage the engine’s temperature. These jackets are integral to the block’s structure, ensuring even distribution of coolant around the cylinders and other critical areas.

-

Oil Gallery: The Cylinder Block houses the oil gallery, a network of passages that distribute lubrication to moving parts. This ensures that all components, including the crankshaft, pistons, and camshaft, receive adequate lubrication.

-

Intake and Exhaust Manifolds: The block is designed to interface with the intake and exhaust manifolds. These manifolds direct the flow of air and fuel into the cylinders and expel exhaust gases, respectively.

-

Mounting Points: The Cylinder Block includes various mounting points for securing the engine to the vehicle’s frame. These points ensure the engine remains stable during operation.

-

Flywheel/Flexplate: The rear of the Cylinder Block mates with the flywheel (in manual transmissions) or flexplate (in automatic transmissions). This connection transmits power from the crankshaft to the transmission.

By understanding how the 4941114 interacts with these components, engineers and mechanics can better appreciate its significance in maintaining the engine’s overall functionality and performance.

Conclusion

The Cummins 4941114 Cylinder Block is a critical component in heavy-duty truck engines, providing a robust framework for efficient engine operation. Its advanced design, compatibility with various Cummins engines, and integration with key engine components underscore its importance in achieving optimal engine performance and longevity.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.