This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

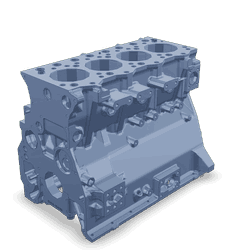

The Cummins 5254544 Cylinder Block is a critical component in heavy-duty truck engines, providing a robust foundation for the engine assembly. This part ensures efficient operation and durability under demanding conditions.

Basic Concepts of a Cylinder Block

A cylinder block, or engine block, houses the cylinders in an internal combustion engine. It provides a rigid framework, supports the crankshaft, and contains the combustion chambers. The block interacts with various engine components, such as the pistons, crankshaft, and cylinder head, to facilitate engine operation 1.

Purpose of the Cummins 5254544 Cylinder Block

This Cummins part provides a sturdy base for the engine’s moving parts, contributing to engine performance and durability. It ensures precise alignment and support for the crankshaft and pistons, designed to withstand high pressures and temperatures, enhancing the engine’s efficiency and reliability 2.

Key Features

The 5254544 boasts several key features that enhance its functionality. These include a robust material composition, typically cast iron or aluminum, which provides excellent strength and heat dissipation. The design elements, such as integrated cooling passages and precise machining, contribute to its performance. Enhanced surface finishes and reinforced structures further improve its durability and efficiency 3.

Benefits

The advantages of the 5254544 include improved engine efficiency, reliability, and longevity. Its robust construction and precise engineering allow for better thermal management and reduced wear on engine components, resulting in enhanced performance and extended service life for the engine.

Design and Construction

The design and construction of the 5254544 involve advanced manufacturing processes and stringent quality control measures. The block is typically cast using high-quality materials and undergoes precise machining to ensure dimensional accuracy. Quality control measures, such as non-destructive testing and rigorous inspection protocols, are employed to ensure the cylinder block meets the highest standards of performance and reliability.

Integration with Other Engine Components

The 5254544 integrates seamlessly with other engine components, such as the crankshaft, pistons, and cylinder head. It provides the necessary support and alignment for the crankshaft, houses the pistons within its cylinders, and interfaces with the cylinder head to form the combustion chambers. This integration ensures smooth and efficient engine operation.

Performance Characteristics

The performance characteristics of the 5254544 include high power output, effective thermal management, and superior vibration control. Its design allows for optimal power generation while maintaining stable operating temperatures and minimizing vibrations, which contributes to the engine’s overall performance and longevity.

Troubleshooting and Maintenance

Common issues that may arise with the 5254544 include wear, cracks, and cooling system failures. Diagnostic procedures involve visual inspections, pressure tests, and analysis of engine performance data. Maintenance practices to ensure optimal performance and longevity include regular inspections, proper lubrication, and timely replacement of worn components. Adhering to manufacturer-recommended maintenance schedules is crucial for preserving the cylinder block’s integrity and performance.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a rich history in the engine industry. The company is known for its commitment to innovation and quality in engine manufacturing. Cummins engines are widely recognized for their reliability, performance, and durability, making them a preferred choice for heavy-duty applications. The company’s dedication to advancing engine technology ensures that its products, including the 5254544, meet the highest standards of excellence.

Cummins Cylinder Block Part 5254544 in Engine Applications

The Cummins Cylinder Block part number 5254544 is a critical component in several engine models, ensuring structural integrity and efficient operation. This part is designed to fit seamlessly into various Cummins engines, providing a robust foundation for other engine components.

B3.3 Engine Series

The B3.3 engine series is one of the prominent applications for the Cummins Cylinder Block part 5254544. This engine is known for its reliability and performance in various industrial and commercial applications. The cylinder block in this series is engineered to handle high stress and provide durability over extended periods of use.

Grouping of Engine Models

The Cummins Cylinder Block part 5254544 is not limited to a single engine model but is compatible with a range of engine configurations within the B3.3 series. This versatility allows for easier maintenance and repair, as the same part can be used across multiple engine variants, reducing inventory needs and simplifying logistics.

Engine Compatibility

When considering the Cummins Cylinder Block part 5254544, it is essential to understand its compatibility with the B3.3 engine series. This part is designed to fit precisely, ensuring that all engine components align correctly and function as intended. The block’s design accommodates various engine specifications, making it a versatile choice for multiple applications.

Installation and Usage

Proper installation of the Cummins Cylinder Block part 5254544 is crucial for the engine’s performance. Technicians should follow manufacturer guidelines to ensure that the block is correctly aligned and secured. This part’s robust construction ensures that it can withstand the rigors of continuous operation, contributing to the engine’s overall longevity and efficiency.

Understanding the Integration of Part 5254544 Cylinder Block in Engine Systems

The part 5254544 Cylinder Block is a fundamental component in the architecture of an engine, serving as the structural backbone that houses the cylinders. This block is meticulously designed to ensure precise alignment and integration with various engine components, facilitating efficient operation and performance.

Key Integrations

Cylinders

The primary role of the cylinder block is to provide a secure and stable environment for the cylinders. Each cylinder within the block is bored to exact specifications to ensure a snug fit for the pistons. The cylinders are aligned in a specific configuration—whether inline, V, or opposed—to optimize the engine’s balance and performance.

Pistons and Connecting Rods

Within the cylinders housed in the block, pistons move up and down in response to the combustion process. The cylinder block features precisely machined bores to accommodate these pistons, ensuring minimal friction and maximum efficiency. Connecting rods attach the pistons to the crankshaft, transferring the linear motion of the pistons into rotational motion.

Crankshaft

The crankshaft is supported by the cylinder block through main bearings. These bearings are housed in machined journals within the block, allowing the crankshaft to rotate smoothly. The alignment between the cylinder block and the crankshaft is vital for maintaining engine balance and reducing vibrations.

Camshaft and Valvetrain

In engines with overhead camshafts, the cylinder block often includes passages and mounting points for the camshaft. The block must be designed to accommodate the camshaft’s position, whether it is mounted directly above the cylinders (OHC) or within the block (SOHC). The cylinder block also integrates with the valvetrain components, ensuring proper timing and operation of the valves.

Cooling System

The cylinder block incorporates water jackets—channels through which coolant flows to manage the engine’s temperature. These jackets are strategically placed around the cylinders and other critical areas to dissipate heat effectively. The block must be designed to interface with the engine’s cooling system, including the water pump and radiator.

Oil System

The cylinder block houses the oil galleries, which distribute lubrication to various engine components. The block includes passages for oil to flow to the crankshaft, camshaft, pistons, and other moving parts. Proper integration with the oil pump and filtration system is essential for maintaining adequate lubrication.

Intake and Exhaust Manifolds

The cylinder block provides mounting points for the intake and exhaust manifolds. These manifolds are responsible for directing air into the cylinders and expelling exhaust gases. The precise fit and sealing between the block and manifolds are necessary to prevent leaks and ensure efficient airflow.

Conclusion

The Cummins 5254544 Cylinder Block is integral to the engine’s operation, providing a stable platform for the cylinders, pistons, crankshaft, and other components. Its design ensures proper alignment, lubrication, cooling, and integration with the engine’s various systems, contributing to overall performance and reliability.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.