This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

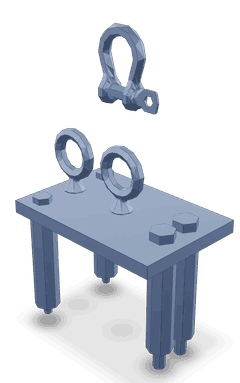

The 3822479 Cylinder Head Lifting Fixture, manufactured by Cummins, is a specialized tool designed for the maintenance and repair of heavy-duty truck engines. This part is integral to the safe and efficient handling of cylinder heads, facilitating their removal and installation during engine service procedures. Cummins, a renowned name in the diesel engine manufacturing industry, ensures that this fixture meets the high standards required for professional engine maintenance 1.

Basic Concepts

Cylinder head lifting fixtures are designed based on fundamental principles of mechanics and safety. These fixtures are engineered to provide a stable and secure platform for lifting and positioning cylinder heads. They operate by evenly distributing the weight of the cylinder head, minimizing the risk of damage to the component and ensuring the safety of the technician. The 3822479 exemplifies these principles, offering a reliable solution for handling cylinder heads in heavy-duty truck engines 2.

Purpose and Function

The primary role of the 3822479 is to assist in the precise removal and installation of cylinder heads in heavy-duty truck engines. This Cummins part is designed to align with the specific contours and weight distribution of cylinder heads, ensuring that they are handled with care. By providing a secure grip and stable platform, it allows technicians to perform maintenance tasks with greater accuracy and safety, reducing the potential for errors or accidents during the process 3.

Key Features

The 3822479 boasts several key features that enhance its functionality and durability. Its design incorporates elements that ensure a firm yet gentle hold on the cylinder head, preventing slippage or damage. The fixture is constructed from high-quality materials, ensuring it can withstand the rigors of frequent use in a professional workshop. Additionally, it is engineered for ease of use, with intuitive adjustments and a design that accommodates various cylinder head sizes and shapes, making it a versatile tool in the technician’s arsenal.

Benefits

Utilizing the 3822479 offers several advantages in engine maintenance procedures. It significantly improves safety by providing a secure method for handling cylinder heads, reducing the risk of injury to technicians. The fixture also enhances efficiency, allowing for quicker and more precise cylinder head removal and installation. Over time, its use can lead to cost savings by minimizing the risk of damage to engine components, which can be both time-consuming and expensive to repair or replace.

Troubleshooting and Maintenance

To ensure the 3822479 remains in optimal working condition, routine maintenance and troubleshooting are recommended. Common issues may include wear on contact points or misalignment, which can be addressed through regular cleaning, inspection, and adjustment. It is important to follow the manufacturer’s guidelines for maintenance to prolong the life of the fixture and ensure its continued reliability and safety.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins is recognized for its innovation, quality, and commitment to customer success. The company’s expertise in diesel engine manufacturing is evident in its comprehensive range of components and tools, like the Cylinder Head Lifting Fixture 3822479, designed to meet the demanding requirements of heavy-duty truck maintenance and repair.

Conclusion

The 3822479 Cylinder Head Lifting Fixture is a critical tool for the maintenance and repair of heavy-duty truck engines, offering enhanced safety, efficiency, and durability. Its design and features cater to the specific needs of engine maintenance, ensuring that technicians can perform their tasks with precision and confidence. Regular maintenance of this Cummins part is essential to ensure its longevity and continued effectiveness in professional workshops.

-

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.