This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

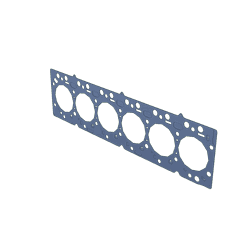

The Cummins 5271251 Cylinder Head Gasket is a critical component in the operation of heavy-duty trucks. It serves as a seal between the cylinder head and the engine block, ensuring the integrity of the combustion chamber and facilitating the efficient operation of the engine.

Basic Concepts of Cylinder Head Gaskets

A Cylinder Head Gasket is a sealing element positioned between the cylinder head and the engine block. Its primary function is to seal the combustion chamber, allowing for the compression of the air-fuel mixture and the containment of combustion pressures. This gasket also plays a role in managing the flow of coolant and oil within the engine, contributing to overall engine performance and efficiency 1.

Purpose of the Cummins 5271251 Cylinder Head Gasket

This Cummins part is designed to seal the combustion chamber effectively, preventing the escape of combustion gases. It also helps in managing engine pressures and temperatures by ensuring proper sealing and thermal management between the cylinder head and the engine block. This gasket is integral to maintaining engine efficiency and reliability under heavy-duty operating conditions 2.

Key Features

The Cummins 5271251 features a robust material composition, typically including multi-layer steel and composite materials, which enhance its durability and performance. Its design incorporates precise milling and surface treatment to ensure a perfect fit and optimal sealing capabilities. Additionally, the gasket may include features such as enhanced sealing beads and combustion chamber pockets to improve its performance under high-pressure and high-temperature conditions 3.

Benefits

This part offers several benefits, including improved engine efficiency through effective sealing of the combustion chamber. Its durable construction ensures long-term reliability, even under the demanding conditions typical of heavy-duty truck operations. The gasket’s design also contributes to stable engine performance, reducing the risk of leaks and failures.

Installation Considerations

Proper installation of this Cummins part is crucial for its effective function. Guidelines for installation include adhering to specified torque settings to ensure the cylinder head is properly secured without over-tightening. Surface preparation is also important, involving cleaning and inspection of mating surfaces to ensure a smooth and contaminant-free interface. Alignment procedures should be followed to guarantee the gasket is correctly positioned between the cylinder head and engine block.

Troubleshooting Common Issues

Common issues with Cylinder Head Gaskets include leaks and failures, often indicated by symptoms such as coolant loss, overheating, or white smoke from the exhaust. Troubleshooting steps involve inspecting the gasket for signs of wear or damage, checking for proper installation, and ensuring mating surfaces are clean and free of contaminants. Addressing these issues promptly can help maintain engine performance and prevent further damage.

Maintenance Tips

To prolong the service life of the Cummins 5271251 and maintain engine performance, regular inspections are recommended. Cleaning the gasket and mating surfaces during routine maintenance can prevent buildup and ensure a proper seal. Replacement guidelines should be followed based on the manufacturer’s recommendations or if signs of wear or failure are detected.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its high-quality engine components and commitment to innovation. With a rich history of producing reliable and efficient engine parts, Cummins has established a reputation for excellence and durability in the heavy-duty truck sector.

Role of Part 5271251 Cylinder Head Gasket in Engine Systems

The Cylinder Head Gasket (part 5271251) is an essential component that ensures the proper functioning of various engine systems. It acts as a seal between the Cylinder Head and the engine block, preventing the leakage of combustion gases, oil, and coolant. This gasket is integral to maintaining the integrity of the engine’s upper section and contributes to overall engine performance.

Interaction with Key Components

- Cylinder Head: The gasket sits between the cylinder head and the engine block, ensuring a tight seal. This prevents combustion gases from escaping into the crankcase or coolant passages, which could lead to reduced engine efficiency and potential damage.

- Camshaft: Positioned above the cylinder head in overhead cam engines, the camshaft relies on the integrity of the head gasket to maintain proper valve operation. Any compromise in the gasket can lead to oil contamination in the combustion chamber, affecting camshaft performance.

- Connecting Rod and Piston: The efficient transfer of power from the pistons to the crankshaft depends on the sealed combustion chamber provided by the head gasket. A leak can result in loss of compression, directly impacting the performance of the connecting rod and piston assembly.

- Upper Engine Gasket Kit: When replacing or repairing the upper engine components, the cylinder head gasket is often included in the gasket kit. Its proper installation is vital for the kit’s effectiveness, ensuring all upper engine seals are intact and functioning correctly.

- Parts and Performance: The head gasket’s role in sealing the combustion chamber directly influences engine performance. A well-sealed chamber ensures optimal compression ratios and efficient fuel combustion, contributing to the engine’s power output and fuel efficiency.

Conclusion

In summary, the Cummins 5271251 Cylinder Head Gasket is a fundamental component that interacts with various engine systems to maintain seals, ensure proper operation, and contribute to the engine’s overall performance. Proper installation, maintenance, and prompt troubleshooting of common issues are essential to maximize the efficiency and reliability of heavy-duty engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.