Introduction to Cylinder Liners

Cylinder liners, also known as sleeves, are integral components in the construction of internal combustion engines. They serve as the inner walls of the engine’s cylinders, providing a smooth surface for the pistons to move against. This reduces friction, wear, and tear, and helps maintain the engine’s efficiency and longevity 1.

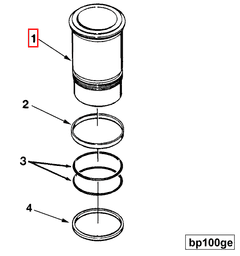

The Role of a Cylinder Liner in Engine Operation

A cylinder liner is crucial for the proper functioning of an engine. It not only provides a smooth surface for the piston rings to seal against but also helps in dissipating heat from the combustion process. The Cummins 3055099 cylinder liner is designed to meet the high-performance demands of commercial truck engines, ensuring durability and reliability under extreme conditions 2.

Purpose of the Cummins 3055099 Cylinder Liner

The Cummins 3055099 cylinder liner is specifically engineered for use in heavy-duty truck engines. Its primary role is to provide a wear-resistant surface that can withstand the high pressures and temperatures generated during combustion. This liner ensures that the engine operates efficiently and maintains its performance over time, even under heavy loads and demanding conditions 3.

How the Cummins 3055099 Cylinder Liner Works

The Cummins 3055099 cylinder liner is typically made from a high-strength, wear-resistant material such as cast iron or steel. It is precision-machined to fit snugly within the engine block, creating a tight seal that prevents oil leakage and maintains compression. The liner’s smooth surface reduces friction, allowing the piston rings to move effortlessly, which in turn enhances fuel efficiency and reduces wear on engine components.

Troubleshooting and Maintenance of the Cummins 3055099 Cylinder Liner

Proper maintenance of the cylinder liner is essential to ensure the longevity and performance of the engine. Here are some troubleshooting tips and maintenance practices:

-

Regular Inspection: Periodically inspect the cylinder liner for signs of wear, such as scoring, pitting, or excessive oil consumption. Any visible damage should be addressed promptly to prevent further engine damage.

-

Proper Lubrication: Ensure that the engine is properly lubricated with high-quality oil. Adequate lubrication reduces friction and wear on the cylinder liner and other engine components.

-

Cooling System Maintenance: A well-maintained cooling system is crucial for dissipating heat from the cylinder liner. Regularly check the coolant levels and ensure that the cooling system is free from leaks and blockages.

-

Piston Ring Maintenance: Inspect the piston rings for wear and ensure they are properly seated in the cylinder liner. Worn or damaged piston rings can cause excessive wear on the cylinder liner.

-

Engine Overheating: Monitor the engine temperature and address any overheating issues immediately. Overheating can cause the cylinder liner to warp or crack, leading to engine failure.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of heavy-duty engines and related components. With a history of innovation and quality, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industries. The company’s commitment to research and development ensures that its products, including the 3055099 cylinder liner, meet the highest standards of performance and reliability.

Expert Insights and Best Practices

As an expert in commercial truck parts, it is important to understand the critical role that the cylinder liner plays in engine operation. Proper maintenance and timely troubleshooting can prevent costly engine repairs and ensure the longevity of your truck’s engine. By following best practices and using high-quality components like the Cummins 3055099 cylinder liner, you can maintain the performance and reliability of your commercial truck.

Cummins Cylinder Liner 3055099 Compatibility

The Cummins Cylinder Liner part number 3055099 is designed to fit a variety of engines, ensuring a reliable and durable solution for engine maintenance and repair. Here is a detailed look at its compatibility across different engine models:

G855 Series

- G855

- G855 CM558

- GTA855 CM558 (CM2358)

The G855 series engines benefit from the 3055099 cylinder liner, which provides a precise fit and enhances the overall performance and longevity of these engines.

N14 Series

- N14 CELECT

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

The N14 series engines, including the CELECT, CELECT PLUS, G, and MECHANICAL variants, are compatible with the 3055099 cylinder liner. This part ensures optimal engine efficiency and durability.

NH/NT 855 Series

- NH/NT 855

The NH/NT 855 engine is another model that can utilize the 3055099 cylinder liner, providing a seamless fit and enhancing engine reliability.

QSN14 Series

- QSN14 CM876 N103

- QSNT14 CM876 N102

The QSN14 series engines, specifically the CM876 N103 and N102 models, are also compatible with the 3055099 cylinder liner, ensuring a precise fit and maintaining engine performance.

V28 Series

- V28

Lastly, the V28 engine is compatible with the 3055099 cylinder liner, offering a reliable solution for maintaining and repairing this engine model.

Role of Part 3055099 Cylinder Liner in Engine Systems

The part 3055099 Cylinder Liner is an integral component in various engine systems, ensuring the efficient and reliable operation of the engine. Here’s how it integrates with the provided components:

Integration with Engine Blocks and Cylinders

The Cylinder Liner fits precisely within the Engine Block, forming the inner surface of the Cylinder. This fit is essential for maintaining the structural integrity of the Cylinder Block and ensuring a smooth surface for the Piston to travel within. In configurations such as the Cylinder Block Kit or the Cylinder Short V-12 Block, the Liner provides a consistent and durable interface that withstands the high pressures and temperatures generated during engine operation.

Role in Short Block and Overhaul Kits

In a Short Block Assembly Kit or a Short Block Kit, the Cylinder Liner is a key component that contributes to the overall performance and longevity of the engine. It is often included in Overhaul Kits to replace worn-out liners, ensuring that the engine maintains optimal compression and efficiency. The Liner W/Piston Rings Kit further enhances this by providing a complete solution for cylinder rejuvenation.

Contribution to Engine Overhaul and Maintenance

During an Engine Overhaul, the Cylinder Liner plays a significant role in restoring the engine to like-new condition. It is commonly found in Engine Overhaul Kits, where it is paired with other critical components such as the Main Bearing Shell and Piston/Liner (PDC) assemblies. This ensures that the engine’s cylinders are in peak condition, facilitating smooth piston movement and efficient combustion.

Use in Onboard Spares and Set of Spares

The Cylinder Liner is also a vital component in On Board Spares and Set of Spares kits. These kits are designed to provide quick and easy replacements during maintenance or repair operations, minimizing downtime and ensuring that the engine can be swiftly returned to service.

Compatibility with Various Engine Configurations

Whether it’s an NTC-300 configuration or an EBM: Block setup, the Cylinder Liner is designed to fit seamlessly within these systems. Its role is to provide a durable and precise surface for the piston’s travel, contributing to the engine’s overall performance and reliability.

Summary of Integration

In summary, the Part 3055099 Cylinder Liner is a fundamental component in various engine systems, from basic Base Parts and Blocks to comprehensive Overhaul Kits and Onboard Spares. Its precise fit and durable construction are essential for maintaining engine efficiency, ensuring smooth operation, and facilitating easy maintenance and repair.

Conclusion

The Cummins 3055099 cylinder liner is a critical component in the operation and maintenance of heavy-duty truck engines. Its role in reducing friction, dissipating heat, and ensuring engine efficiency cannot be overstated. Proper maintenance and timely troubleshooting are essential to ensure the longevity and performance of the engine. By understanding the importance of this part and following best practices, you can maintain the reliability and efficiency of your commercial truck’s engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.