This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

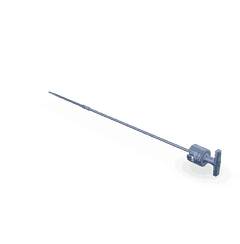

The Oil Level Dipstick 2899843 by Cummins is a component designed to facilitate the monitoring of engine oil levels in heavy-duty trucks. This Cummins part plays a significant role in the maintenance routine of these vehicles, ensuring that the engine operates within optimal parameters. Cummins, a well-regarded manufacturer in the automotive industry, produces this dipstick with a focus on durability and accuracy, contributing to the overall reliability of truck engines 1.

Basic Concepts of an Oil Level Dipstick

An oil level dipstick is a tool used to measure the amount of oil within an engine. Its primary function is to provide a quick and straightforward method for checking the oil level, which is crucial for maintaining engine health. The dipstick typically consists of a long, thin metal or plastic rod with a handle at one end. One side of the rod is usually marked with graduated measurements to indicate the oil level. When inserted into the engine’s oil filler tube and then withdrawn, the oil coating on the dipstick can be compared against these markings to determine the current oil level 2.

Purpose and Role in Truck Operation

The Oil Level Dipstick 2899843 is integral to the operation and maintenance of heavy-duty trucks. It aids in monitoring engine oil levels, which is vital for ensuring optimal engine performance. Proper oil levels are necessary for lubrication, cooling, and cleaning within the engine. By regularly checking the oil level with this dipstick, truck operators can prevent engine wear, overheating, and other issues that may arise from insufficient lubrication 3.

Key Features

The Oil Level Dipstick 2899843 features several design elements that set it apart from other models. It is constructed from high-quality materials to ensure durability under the demanding conditions of heavy-duty truck engines. The dipstick is designed with precise measurement markings for accurate readings. Additionally, its robust construction allows it to withstand the high temperatures and pressures within the engine compartment.

Benefits of Using Oil Level Dipstick 2899843

Utilizing the Oil Level Dipstick 2899843 offers several advantages. The accuracy of its oil level readings helps maintain the engine within the manufacturer’s recommended oil levels, contributing to engine longevity and performance. Its durable construction ensures it can withstand the rigors of heavy-duty use, while its ease of use makes routine oil checks straightforward for operators.

Installation and Usage Instructions

To install and use the Oil Level Dipstick 2899843, follow these steps: First, ensure the truck is on a level surface and the engine is off. Locate the dipstick tube, usually found near the engine’s top. Pull out the dipstick, wipe it clean with a lint-free cloth, reinsert it fully, and then pull it out again to check the oil level against the markings. This procedure should be performed regularly as part of the truck’s maintenance schedule to ensure accurate oil level readings and maintain engine efficiency.

Troubleshooting Common Issues

Common issues with oil level dipsticks include inaccurate readings due to contamination or damage. To troubleshoot, first, ensure the dipstick is clean and free from debris. If readings are consistently inaccurate, inspect the dipstick for signs of wear or damage. In cases where the dipstick appears damaged or if readings remain unreliable, replacement may be necessary to ensure accurate oil level monitoring.

Maintenance Tips

To maintain the Oil Level Dipstick 2899843 and ensure its longevity and accuracy, regular cleaning is recommended. After each use, wipe the dipstick clean with a lint-free cloth to remove any oil residue. Inspect the dipstick regularly for signs of wear or damage, and store it in a clean, dry place when not in use. These practices will help preserve the dipstick’s condition and ensure reliable oil level readings.

Importance of Regular Oil Level Checks

Regular oil level checks are important for the health of a truck’s engine. Neglecting oil level maintenance can lead to insufficient lubrication, increased friction, and potential engine damage. By incorporating regular oil checks into the maintenance routine, operators can help prevent engine wear, ensure optimal performance, and extend the engine’s lifespan.

Cummins: A Brief Overview

Cummins is a company with a rich history in the manufacturing of automotive components, known for its commitment to quality and innovation. Established with a focus on producing reliable and efficient engines and components, Cummins has built a reputation for excellence in the industry. Their products, including the Oil Level Dipstick 2899843, reflect this dedication to quality, offering truck operators reliable tools for maintaining their vehicles.

Cummins Oil Level Dipstick 2899843 Compatibility

The Cummins Oil Level Dipstick part number 2899843 is designed to fit seamlessly with several engine models, ensuring accurate oil level monitoring and maintenance. This dipstick is compatible with the following engines:

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

These engines, while distinct in their specifications, share a commonality in their oil monitoring systems, making the 2899843 dipstick a versatile choice for maintenance personnel. The dipstick’s design ensures it fits snugly into the designated oil level check port, providing a reliable means to check oil levels and maintain engine health.

Role of Part 2899843 Oil Level Dipstick in Engine Systems

The part 2899843 Oil Level Dipstick is an essential component in the maintenance and operation of engine systems. It works in conjunction with several other components to ensure the engine operates efficiently and safely.

Interaction with the Oil Level Gauge

The oil level dipstick interfaces directly with the oil level gauge, which is typically located on the instrument panel of the vehicle. When the dipstick is inserted into the engine, it collects a sample of the engine oil. Upon removal, the oil level can be read against the markings on the dipstick. This information is then relayed to the oil level gauge, allowing for a visual indication of the oil level within the engine. This interaction is vital for the gauge to provide accurate readings to the operator, ensuring that the engine is neither overfilled nor underfilled with oil.

Ensuring Proper Oil Level

Maintaining the correct oil level is fundamental for the lubrication of moving parts within the engine. The dipstick plays a key role in this process by providing a simple yet effective method for checking the oil level. When the oil level is low, the dipstick will show less oil, prompting the operator to add more. Conversely, if the oil level is too high, the dipstick will indicate this, preventing potential damage to the engine from overfilling.

Integration with Engine Components

The dipstick is designed to fit into the engine’s oil filler neck, which is connected to the oil pan where the engine oil is stored. This placement allows for a direct measurement of the oil within the pan. The dipstick tube is typically sealed to prevent oil leaks, ensuring that the oil level reading is accurate and that no oil is lost during the checking process.

Role in Maintenance Routines

During regular maintenance checks, the dipstick is an indispensable tool. It allows mechanics and engineers to quickly assess the oil level without dismantling any part of the engine. This ease of use makes it a preferred method for routine oil level checks, contributing to the overall efficiency of maintenance procedures.

Supporting Engine Health

By ensuring that the oil level is consistently monitored and maintained, the dipstick indirectly supports the health of the engine. Proper oil levels contribute to reduced friction and wear on engine components, enhancing the engine’s longevity and performance.

Conclusion

In summary, the part 2899843 Oil Level Dipstick is a simple yet integral component in the engine system, working seamlessly with the oil level gauge and other engine components to maintain optimal oil levels and support engine health.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.