This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

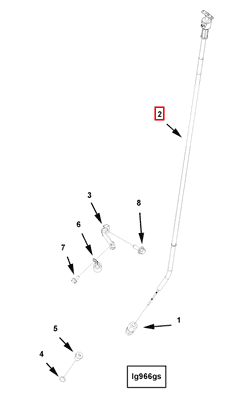

The Cummins 2899878 Dipstick is a specialized component designed for use in commercial trucks. It serves a vital role in the routine maintenance of these vehicles by allowing technicians to monitor engine oil levels accurately. Ensuring proper oil levels is fundamental to the longevity and efficiency of the engine, making the dipstick an indispensable tool in regular vehicle inspections 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet crucial tool used in internal combustion engines to measure the level of lubricant, typically oil. It consists of a long, thin metal or plastic rod with a handle at one end. The rod is inserted into the engine’s oil sump through a tube. Once inserted and then withdrawn, the oil level can be read from the markings on the dipstick, which indicate whether the oil is within the optimal range. This process helps in maintaining the engine’s lubrication system, ensuring that all moving parts are adequately coated with oil to reduce friction and wear 2.

Purpose of the Cummins 2899878 Dipstick

The Cummins 2899878 Dipstick is specifically engineered to facilitate the checking of oil levels in Cummins engines found in commercial trucks. Its design and construction are tailored to the unique requirements of these engines, ensuring that oil levels can be accurately assessed under various operating conditions. This dipstick plays a role in the maintenance routine by providing a straightforward method for technicians to verify that the engine has sufficient oil, which is necessary for optimal performance and longevity 3.

Key Features

The Cummins 2899878 Dipstick is characterized by several key features that enhance its functionality and reliability. It is constructed from high-quality materials to withstand the harsh environments typical of commercial truck operations. The dipstick is designed with precise markings for accurate oil level readings. Additionally, its robust construction ensures durability, reducing the need for frequent replacements. The handle is ergonomically designed for ease of use, allowing for comfortable and secure handling during inspections 4.

Benefits of Using the Cummins 2899878 Dipstick

Utilizing the Cummins 2899878 Dipstick offers several advantages. Its accurate readings help ensure that the engine maintains the correct oil level, which is vital for engine health. The dipstick’s durable construction means it can withstand the rigors of commercial truck use, providing long-term reliability. Furthermore, its ease of use simplifies the maintenance process, allowing technicians to quickly and efficiently check oil levels as part of their routine inspections.

Troubleshooting and Maintenance Suggestions

Common issues with dipsticks may include inaccurate readings due to wear or contamination. To address these, it is advisable to regularly inspect the dipstick for signs of damage or buildup and clean it as necessary to ensure accurate readings. Additionally, ensuring the dipstick tube is free from obstructions can help maintain its functionality. Regular maintenance of the dipstick and its associated components contributes to the overall reliability of the engine’s lubrication system.

Installation and Usage Guidelines

Proper installation and usage of the Cummins 2899878 Dipstick are critical for accurate oil level readings and engine maintenance. To install, ensure the engine is off and has had time to cool. Insert the dipstick fully into its tube, then withdraw it and read the oil level against the markings. For usage, follow the manufacturer’s guidelines for checking oil levels at regular intervals, typically during routine maintenance checks. This practice helps in maintaining optimal engine performance and longevity.

Safety Considerations

When using the Cummins 2899878 Dipstick, it is important to observe safety practices to prevent injury and ensure accurate readings. Always allow the engine to cool before checking the oil level to avoid burns from hot surfaces. Handle the dipstick carefully to prevent damage, and ensure it is fully seated in its tube during use. Accurate interpretation of the dipstick readings is crucial for maintaining proper oil levels, so take care to read the markings clearly and correctly.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and performance in the commercial truck industry. Their commitment to innovation and customer satisfaction has made them a preferred choice for engine solutions in commercial vehicles worldwide.

Role of Part 2899878 Dipstick in Engine Systems

The part 2899878 dipstick is an essential component in the oil level gauge system of an engine. It facilitates the accurate measurement and monitoring of the oil level within the engine’s crankcase.

When inserted into the oil filler tube, the dipstick provides a direct interface for the oil level gauge to interact with the engine’s lubrication system. The oil level gauge relies on the dipstick to draw an oil sample, which is then analyzed to determine the current oil level. This process ensures that the engine maintains optimal lubrication, preventing both overfilling and underfilling of oil.

The dipstick also plays a part in the overall health monitoring of the engine. By regularly checking the oil level via the dipstick, mechanics can identify potential issues such as oil leaks or excessive oil consumption, allowing for timely maintenance and repairs. Additionally, the dipstick allows for the inspection of oil quality, enabling the detection of contaminants or degradation that may indicate the need for an oil change.

Conclusion

In summary, the Cummins 2899878 Dipstick is integral to the proper functioning of the oil level gauge, ensuring that the engine remains well-lubricated and operates efficiently. Its accurate readings, durable construction, and ease of use make it a vital tool in the maintenance of Cummins engines in commercial trucks.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Wharton, A. J. Diesel Engines. Butterworth-Heinemann Ltd, 1991.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.