This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hydraulic Variable Timing Tappet (HVTT), specifically Part #3082587 by Cummins, represents a significant advancement in the technology of modern diesel engines. This component is integral to the efficient operation of the engine’s valve train, allowing for dynamic adjustments to valve timing. Cummins, a prominent manufacturer in the automotive and heavy-duty truck industries, has a long-standing reputation for producing high-quality engine components that enhance performance and reliability 1.

Basic Concepts of Hydraulic Variable Timing Tappet

The fundamental principle behind hydraulic variable valve timing involves the use of hydraulic pressure to adjust the timing of valve operation within an engine. The HVTT operates by altering the phase angle of the camshaft relative to the crankshaft, which in turn modifies the opening and closing times of the engine’s valves. This adjustment allows the engine to optimize performance across a range of operating conditions, enhancing both efficiency and power output 2.

Operation and Role in Truck Engines

This Cummins part plays a role in the operation of truck engines by enabling precise control over valve timing. This control contributes to improved engine performance by allowing the engine to operate more efficiently under varying loads and speeds. Additionally, the HVTT aids in emissions control by ensuring that the engine runs at optimal efficiency, reducing the production of harmful pollutants. The tappet’s ability to adjust valve timing also contributes to better fuel economy, making it a valuable component in the pursuit of more sustainable transportation solutions 3.

Key Features

The 3082587 HVTT is characterized by several key features that enhance its functionality and durability. Its design incorporates advanced materials that resist wear and corrosion, ensuring long-term reliability. Cummins has integrated technological advancements into the HVTT, such as improved hydraulic control systems, to provide more precise adjustments to valve timing. These features contribute to the overall performance and longevity of the component.

Benefits of Using Hydraulic Variable Timing Tappet

The use of the HVTT offers several benefits, including improved fuel efficiency due to optimized engine operation across a range of conditions. It also contributes to reduced emissions, aligning with environmental regulations and standards. Enhanced engine performance is another advantage, as the HVTT allows for better power output and responsiveness. Additionally, the durability of the HVTT ensures that it can withstand the rigors of heavy-duty truck operation, providing long-term value to the user.

Installation and Integration

Proper installation and integration of the 3082587 HVTT into truck engines are crucial for ensuring optimal performance. Guidelines for installation should be followed to maintain the integrity of the valve train system. The HVTT is designed to be compatible with a variety of engine models and configurations, though specific compatibility details should be consulted to ensure proper fit and function.

Troubleshooting and Maintenance

Common issues associated with the HVTT may include hydraulic leaks, phaser malfunctions, or sensor failures. Troubleshooting steps should begin with a thorough inspection of the hydraulic system for leaks or damage. Maintenance practices for the HVTT include regular checks of the hydraulic fluid level and condition, as well as monitoring the operation of the phaser and sensors. Adhering to these practices will help ensure the optimal performance and longevity of the component.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a strong reputation for innovation, quality, and reliability in the automotive and diesel engine industry. Their product portfolio includes engines, filtration systems, powertrain-related components, and emission solutions, catering to a diverse range of applications from on-highway to off-highway and stationary power.

Hydraulic Variable Timing Tappet (Part 3082587) in Cummins Engines

The Hydraulic Variable Timing Tappet, identified by the part number 3082587, is a critical component in the Cummins N14 engine family. This part is integral to the engine’s performance and efficiency, particularly in the N14 CELECT PLUS and N14 MECHANICAL variants.

In the N14 CELECT PLUS engine, the Hydraulic Variable Timing Tappet is designed to work seamlessly with the engine’s advanced electronic control system. This integration allows for precise timing adjustments, enhancing fuel efficiency and reducing emissions. The tappet’s hydraulic system responds to engine load and speed, ensuring optimal performance across various operating conditions.

Similarly, in the N14 MECHANICAL engine, the Hydraulic Variable Timing Tappet plays a crucial role in maintaining engine timing. Although this variant lacks the electronic control system found in the CELECT PLUS, the tappet still provides essential timing adjustments. The mechanical design ensures that the tappet can adapt to the engine’s demands, contributing to reliable performance and longevity.

Both engines benefit from the Hydraulic Variable Timing Tappet’s ability to adjust valve timing dynamically. This feature is particularly important in heavy-duty applications where consistent power and efficiency are paramount. The tappet’s design allows for smooth and precise timing changes, which can significantly impact the engine’s overall performance and durability.

Role of Part 3082587 Hydraulic Variable Timing Tappet in Engine Systems

The integration of the Hydraulic Variable Timing Tappet (HVTT), part 3082587, within engine systems is a sophisticated process that enhances engine performance and efficiency. This component is pivotal in the synchronization of valve timing, which is essential for optimal combustion and power output.

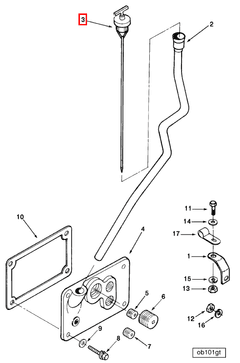

Arrangement

In the engine’s arrangement, the HVTT is strategically positioned to interact with the camshaft and valve train. Its placement allows for precise control over the valve timing, which is adjusted based on engine load and speed. This arrangement ensures that the valves open and close at the most efficient times, contributing to improved fuel efficiency and reduced emissions.

Oil Fill

The HVTT relies on a consistent oil fill to operate effectively. The oil fill system ensures that the tappet receives a steady supply of lubricant, which is vital for its hydraulic functions. Proper lubrication minimizes friction and wear on the tappet and associated components, ensuring smooth operation and longevity of the engine system.

Gauge

A gauge is often incorporated into the engine system to monitor the performance of the HVTT. This gauge provides real-time data on the tappet’s operation, allowing engineers and mechanics to make necessary adjustments. By monitoring parameters such as oil pressure and temperature, the gauge helps maintain the HVTT within optimal operating conditions, ensuring reliable engine performance.

Oil Level

Maintaining the correct oil level is essential for the HVTT’s function. The oil level sensor works in conjunction with the oil fill system to ensure that the tappet is always adequately lubricated. An appropriate oil level prevents hydraulic lock and ensures that the tappet can respond quickly to changes in engine conditions, thereby enhancing overall engine efficiency and reliability.

Conclusion

The Hydraulic Variable Timing Tappet (HVTT), part 3082587 by Cummins, is a sophisticated component that significantly enhances the performance and efficiency of diesel engines. Its ability to dynamically adjust valve timing based on engine load and speed contributes to improved fuel efficiency, reduced emissions, and enhanced engine performance. Proper installation, maintenance, and troubleshooting are essential to ensure the optimal operation of this part, making it a valuable asset in the pursuit of more sustainable and reliable engine solutions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.