This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

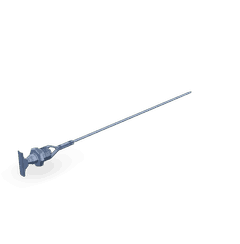

The Cummins 3085838 Dipstick is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the monitoring of oil levels within the engine, ensuring that the lubrication system operates within the manufacturer’s specified parameters. This part is significant in the maintenance regimen of commercial trucks, as it allows for regular checks that can prevent engine wear and potential failures.

Basic Concepts of a Dipstick

A dipstick is a simple yet vital tool used in internal combustion engines to measure the level of lubricant, typically oil. It consists of a long, slender rod with a handle at one end, which is inserted into the engine’s oil sump. Once inserted and then withdrawn, the oil level can be read from the markings on the dipstick. This process is fundamental for maintaining the engine’s lubrication system, as it ensures that there is sufficient oil to reduce friction between moving parts, cool the engine, and remove contaminants 1.

Purpose of the Cummins 3085838 Dipstick

The Cummins 3085838 Dipstick is specifically engineered to play a role in the operation and maintenance of commercial trucks by providing a means to check oil levels. It is designed to fit into the oil sump of Cummins engines, allowing technicians and operators to quickly and accurately assess the oil level. This is particularly important in commercial trucks, where engine performance and longevity are critical to operational efficiency and safety 2.

Key Features

The Cummins 3085838 Dipstick is characterized by its robust design and the materials used in its construction. It is typically made from high-quality steel, which ensures durability and resistance to the high temperatures and pressures within the engine compartment. The dipstick is also designed with a clear and easy-to-read marking system, which aids in accurate oil level measurement. Additionally, its length and diameter are tailored to fit precisely within the oil sump of Cummins engines, ensuring a secure fit and reliable readings 3.

Benefits

Using the Cummins 3085838 Dipstick offers several advantages. Its design ensures accuracy in fluid level measurement, which is crucial for maintaining engine health. The materials used in its construction contribute to its durability, making it resistant to wear and corrosion. Furthermore, the dipstick is easy to use, requiring no special tools for operation, which simplifies the maintenance process for commercial truck operators 4.

Installation Process

Installing the Cummins 3085838 Dipstick involves a few straightforward steps. First, ensure the engine is turned off and has cooled down to avoid burns from hot oil. Then, locate the dipstick tube, which is usually found on the side of the engine block. Remove the old dipstick by pulling it straight out of the tube. Insert the new Cummins 3085838 Dipstick into the tube until it is fully seated. Finally, withdraw the dipstick to check the oil level, ensuring it falls within the recommended range 5.

Troubleshooting Common Issues

Common issues with dipsticks include inaccurate readings and physical damage. Inaccurate readings can often be attributed to incorrect installation or contamination on the dipstick. To address this, ensure the dipstick is fully seated when taking a reading and clean it with a lint-free cloth before reinserting it. Physical damage, such as bends or cracks, can affect the dipstick’s functionality. If damage is detected, the dipstick should be replaced to ensure accurate oil level measurements 6.

Maintenance Tips

To ensure the longevity and accurate performance of the Cummins 3085838 Dipstick, regular maintenance is recommended. This includes cleaning the dipstick after each use to remove any oil residue and contaminants. Inspect the dipstick regularly for signs of wear or damage, and replace it if necessary. Additionally, ensure the dipstick tube is free from obstructions and contaminants, as these can affect the accuracy of the oil level readings 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is renowned for its commitment to quality and innovation, consistently delivering reliable and efficient automotive components that meet the demanding requirements of commercial applications 8.

Cummins Engine Dipstick 3085838 Compatibility

The Cummins engine dipstick part number 3085838 is designed to be compatible with a range of Cummins diesel engines. This part is essential for checking the oil level in the engine, ensuring that the engine is properly lubricated and functioning optimally.

QSK19 Series Engines

The Cummins QSK19 series engines, including the QSK19 CM2350 K114, QSK19 CM500, and QSK19 CM850 MCRS, are all compatible with the dipstick part number 3085838. These engines are known for their reliability and efficiency, often used in heavy-duty applications such as marine and industrial settings.

The dipstick fits seamlessly into the designated oil level check port on these engines, providing an accurate reading of the oil level. This compatibility ensures that operators can easily monitor and maintain the oil levels in these powerful engines, contributing to their longevity and performance.

Installation and Usage

Installing the dipstick into the engine is a straightforward process. Operators should ensure that the engine is turned off and has cooled down before checking the oil level. The dipstick should be inserted fully into the designated port, then removed and wiped clean. The oil level can then be checked against the markings on the dipstick to determine if the oil level is within the acceptable range.

Regular checks using the dipstick part number 3085838 are crucial for maintaining the health of the engine. Ensuring that the oil level is correct helps prevent engine damage and extends the service life of the engine components 9.

Role of Part 3085838 Dipstick in Engine Systems

The part 3085838 dipstick is an essential component in the accurate measurement and monitoring of oil levels within an engine system. It interfaces directly with the oil level gauge, ensuring that the gauge provides precise readings to the operator or automated system.

When the dipstick is inserted into the engine’s oil sump, it collects a sample of the oil. Upon removal, the oil level can be visually inspected or measured using the markings on the dipstick. This data is then relayed to the oil level gauge, which displays the current oil level status.

The dipstick also plays a role in maintaining the engine’s lubrication system efficiency. By providing consistent and reliable oil level data, it helps in preventing oil starvation or overfilling, both of which can lead to engine damage. Additionally, the dipstick aids in the early detection of oil leaks or consumption issues, allowing for timely maintenance and repairs.

In summary, the part 3085838 dipstick is integral to the proper functioning of the oil level gauge and the overall health of the engine system 10.

Conclusion

The Cummins 3085838 Dipstick is a critical component in the maintenance and operation of commercial truck engines. Its robust design, ease of use, and compatibility with a range of Cummins engines make it an indispensable tool for ensuring engine health and longevity. Regular maintenance and proper usage of this part are essential for preventing engine damage and ensuring optimal performance.

-

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles (SAE International, 2014).

↩ -

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

Kazimierz Lejda and Pawel Wos, Internal Combustion Engines (InTech, 2012).

↩ -

Cummins Inc., Operation and Maintenance Manual for X15 CM2350 X129B (Bulletin Number 5504556).

↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles (SAE International, 2014).

↩ -

Cummins Inc., Company Overview (Cummins Inc., 2023).

↩ -

Cummins Inc., Operation and Maintenance Manual for X15 CM2350 X129B (Bulletin Number 5504556).

↩ -

Kazimierz Lejda and Pawel Wos, Internal Combustion Engines (InTech, 2012).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.