This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

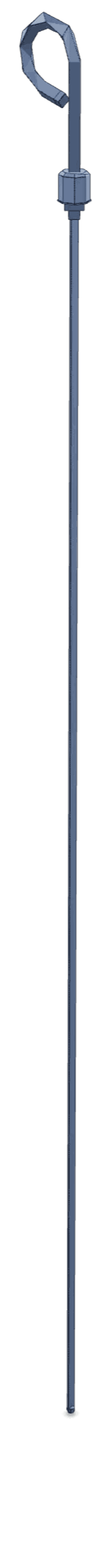

The Cummins 3282867 Dipstick is a specialized component designed for use in heavy-duty trucks. It serves a significant role in the maintenance and operation of these vehicles by facilitating the measurement of oil levels within the engine. Proper oil levels are vital for ensuring adequate lubrication, which in turn supports engine performance and longevity 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in engine systems to measure the level of fluid, typically oil. It consists of a long, slender metal or plastic rod with a handle at one end. The rod is inserted into the engine’s oil reservoir, and upon removal, the oil level can be read from the markings on the dipstick. This process allows for the assessment of whether the oil level is within the appropriate range for safe and efficient engine operation 2.

Purpose of the 3282867 Dipstick

The Cummins 3282867 Dipstick is specifically engineered to monitor oil levels in heavy-duty truck engines. By providing accurate readings of the oil level, it plays a role in ensuring that the engine remains properly lubricated. This is important for maintaining engine performance, preventing wear and tear, and avoiding potential damage from insufficient lubrication 3.

Key Features

This Cummins part is characterized by several design and material features that enhance its durability and accuracy. It is made from materials that offer resistance to corrosion, ensuring longevity even in the harsh environments typical of heavy-duty truck operations. Additionally, the dipstick features precise measurement markings, allowing for accurate assessment of oil levels. These characteristics contribute to the reliability and effectiveness of the dipstick in its role 4.

Benefits

Utilizing the Cummins 3282867 Dipstick offers several advantages. It contributes to improved engine maintenance by providing accurate oil level readings, which are crucial for timely oil changes and top-ups. This, in turn, can lead to extended engine life and enhanced operational efficiency, as the engine operates under optimal lubrication conditions.

Troubleshooting and Maintenance

Common issues with dipsticks may include inaccurate readings or physical damage. To address these, regular inspection of the dipstick for signs of wear or corrosion is recommended. Cleaning the dipstick before each use can help ensure accurate readings. If damage is detected, replacement of the dipstick is advised to maintain the integrity of oil level measurements.

Installation and Usage

Proper installation and usage of the Cummins 3282867 Dipstick involve a few key steps. First, ensure the engine is turned off and has had sufficient time to cool. Locate the dipstick tube, typically found near the engine’s oil fill cap. Insert the dipstick fully into the tube, then remove it and check the oil level against the markings. For accurate readings, wipe the dipstick clean, reinsert it fully, and then check the level again. Always follow safety precautions and refer to the vehicle’s manual for specific instructions.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and related components. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. Their product range includes engines, filtration systems, and other components designed to meet the demanding requirements of heavy-duty applications.

Cummins Engine Dipstick Compatibility

The Cummins part number 3282867, which is a dipstick, is designed to be compatible with several engine models. Specifically, it fits with the following engines:

- 6B5.9

- QSB5.9 30 CM550

- QSB5.9 44 CM550

These engines, while distinct in their specifications and applications, share a commonality in their requirement for the 3282867 dipstick. This part is integral for maintaining the proper oil levels in these engines, ensuring optimal performance and longevity.

For the 6B5.9 engine, the dipstick is essential for regular maintenance checks, allowing operators to verify oil levels without needing to open the engine compartment. Similarly, for the QSB5.9 30 CM550 and QSB5.9 44 CM550 engines, the dipstick serves the same critical function, facilitating easy and accurate oil level assessments.

By ensuring that the dipstick is correctly installed and used, engine operators can maintain the health of their engines, preventing potential damage from either overfilling or underfilling the oil.

Role of Part 3282867 Dipstick in Engine Systems

The part 3282867 dipstick is an essential component in the oil management system of an engine. Its primary function is to provide a means for checking the oil level within the engine’s crankcase. This is achieved through the oil level gauge, which is integrated into the dipstick’s design.

When the dipstick is inserted into the engine, it reaches the oil sump where the engine oil is stored. Upon removal, the oil level can be read directly from the markings on the dipstick. This simple yet effective mechanism allows for regular monitoring of the oil level, ensuring that it remains within the optimal range for engine performance and longevity.

Additionally, the dipstick plays a role in the pressure relief system of the engine. The small hole at the end of the dipstick tube allows for the release of pressure build-up within the crankcase, which can occur during engine operation. This pressure relief is important for maintaining a stable environment within the engine, preventing oil leaks, and ensuring consistent oil flow to all lubricated components.

Conclusion

In summary, the Cummins 3282867 Dipstick is a fundamental component in the engine’s oil management system, facilitating both the monitoring of oil levels and the regulation of crankcase pressure. Its design and features ensure durability and accuracy, contributing to the overall maintenance and performance of heavy-duty truck engines.

-

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.