This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3640868 Dipstick is a component designed for use in heavy-duty trucks, specifically for monitoring engine oil levels. Its role in the maintenance routine of these vehicles is significant, as it allows for the regular assessment of oil levels, which is vital for the engine’s performance and longevity 1.

Basic Concepts of a Dipstick

A dipstick is a tool used in engines to measure the level of lubricant within the system. It consists of a long, thin metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil sump. The principle behind its operation is straightforward: by withdrawing the dipstick and observing the oil level marked on it, one can determine whether the oil level is within the acceptable range 2.

Purpose of the Cummins 3640868 Dipstick

The Cummins 3640868 Dipstick serves a specific function in the operation and maintenance of a truck’s engine. It is primarily used to check the oil level within the engine. Maintaining the correct oil level is important for lubricating moving parts, cooling the engine, and cleaning internal components. Regular checks with the dipstick help ensure that the engine operates efficiently and reduces the risk of damage due to insufficient lubrication 3.

Key Features

The Cummins 3640868 Dipstick is designed with several features that enhance its durability and accuracy. It is constructed from high-quality materials to withstand the harsh conditions within an engine compartment. The dipstick is marked with clear, easy-to-read indicators for minimum and maximum oil levels, ensuring accurate readings. Its design also includes a robust handle for easy gripping and a tapered tip for a snug fit within the oil filler tube 4.

Benefits

Using the Cummins 3640868 Dipstick offers several advantages. Regular oil level checks with this dipstick contribute to improved engine performance by ensuring that the engine is properly lubricated. This practice can lead to prolonged engine life, as consistent lubrication reduces wear on engine components. Additionally, the dipstick’s design promotes ease of use and accuracy, making maintenance routines more efficient 5.

Installation and Usage

To install and use the Cummins 3640868 Dipstick, follow these steps: First, ensure the engine is turned off and has had sufficient time to cool. Locate the dipstick tube, usually found near the engine’s top. Pull the dipstick out completely, wipe it clean with a lint-free cloth, reinsert it fully, and then pull it out again to check the oil level. For an accurate reading, ensure the dipstick is read at eye level and that the engine is on a level surface 6.

Troubleshooting and Maintenance

Common issues with dipsticks include inaccurate readings due to a bent dipstick or incorrect installation. To troubleshoot, check the dipstick for any visible damage and ensure it is fully seated in the tube when taking a reading. Regular maintenance of the dipstick involves keeping it clean and checking for any signs of wear or damage. If the dipstick becomes difficult to read or shows signs of damage, it should be replaced to ensure accurate oil level readings 7.

Safety Considerations

When using the dipstick, it is important to follow safety practices to avoid injuries. Always wait for the engine to cool before checking the oil level to prevent burns from hot surfaces or oil. Use caution when handling the dipstick to avoid dropping it into the engine compartment, where it could cause damage. Additionally, ensure that the area around the dipstick is clean and free from debris to prevent contamination of the engine oil 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation in the automotive industry, particularly in the production of diesel engines and components. The company is known for its commitment to quality, reliability, and performance, making it a trusted name in the heavy-duty truck and engine market 9.

Role of Part 3640868 Dipstick in Engine Systems

The Cummins 3640868 Dipstick is an essential component in the maintenance and operation of engine systems. It is strategically positioned to interact with several key components, ensuring the engine operates efficiently and safely.

Interaction with the Oil Level Gauge

The dipstick is directly connected to the oil level gauge, a fundamental instrument in monitoring the engine’s lubrication system. When the dipstick is inserted into its tube, it provides a physical connection to the oil reservoir. This allows the oil level gauge to accurately read the amount of oil present. The dipstick’s design ensures that it can effectively transfer the oil level information to the gauge, enabling mechanics and engineers to make informed decisions about oil changes and maintenance schedules 10.

Ensuring Accurate Oil Level Readings

Accurate oil level readings are vital for the engine’s performance and longevity. The dipstick’s role in this process cannot be overstated. By providing a clear and reliable method for checking the oil level, it helps prevent issues such as oil starvation, which can lead to severe engine damage. Regular use of the dipstick in conjunction with the oil level gauge allows for proactive maintenance, ensuring that the engine remains well-lubricated and operates within optimal parameters 11.

Facilitating Maintenance Procedures

During routine maintenance, the dipstick is a tool that facilitates several procedures. It allows for the easy checking of oil levels without the need for complex disassembly. This simplicity and efficiency are particularly important in high-maintenance environments where time and accuracy are essential. The dipstick’s design ensures that it can withstand the rigors of frequent use, providing consistent performance over time 12.

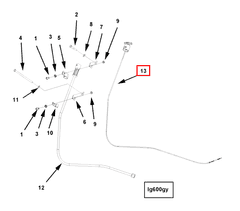

Integration with Engine Systems

The dipstick’s location within the engine system is carefully considered to ensure it can effectively perform its function. It is typically positioned near the oil fill cap, allowing for easy access during inspections. This strategic placement ensures that the dipstick can accurately reflect the oil level, providing mechanics with the information they need to maintain the engine’s health 13.

Conclusion

In summary, the Cummins 3640868 Dipstick plays a significant role in the engine system by facilitating accurate oil level readings, simplifying maintenance procedures, and ensuring the engine remains well-lubricated. Its integration with the oil level gauge and strategic location within the engine system underscore its importance in maintaining engine performance and longevity 14.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.