This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

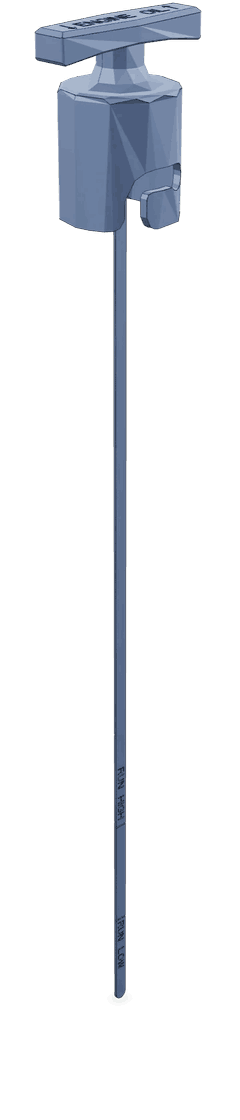

The Cummins 3642469 Dipstick is a component designed for use in commercial trucks equipped with Cummins engines. Its primary function is to facilitate the measurement and monitoring of engine oil levels, which is vital for the proper operation and longevity of the engine.

Basic Concepts of a Dipstick

A dipstick is a tool used in engine maintenance. It consists of a long, slender metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil sump. The dipstick allows mechanics and operators to check the oil level within the engine by providing a visual and tactile means to gauge the oil quantity. Regular oil level checks are important for maintaining engine health, as they help prevent issues such as oil starvation or overfilling, both of which can lead to engine damage 1.

Purpose of the Cummins 3642469 Dipstick

The Cummins 3642469 Dipstick is specifically engineered to monitor engine oil levels in commercial trucks. By providing accurate readings of the oil level, it enables operators to ensure that the engine is adequately lubricated. This is particularly important in heavy-duty applications where engines operate under strenuous conditions.

Key Features

The Cummins 3642469 Dipstick is characterized by its robust design and high-quality materials. It is typically made from durable metals to withstand the harsh environment of a commercial truck engine. The dipstick features clear markings for minimum and maximum oil levels, ensuring precise measurement. Additionally, its design may include a spring-loaded mechanism to secure it in place within the engine.

Benefits of Using the Cummins 3642469 Dipstick

Utilizing the Cummins 3642469 Dipstick offers several advantages. Its accurate measurement capabilities help maintain optimal oil levels, contributing to engine efficiency and longevity. The dipstick’s durable construction ensures it can withstand the rigors of commercial truck operation, providing reliable service over time. Furthermore, its ease of use allows for quick and convenient oil level checks, facilitating routine maintenance procedures.

Installation Process

Installing the Cummins 3642469 Dipstick involves several steps. First, locate the dipstick tube on the engine. Remove the old dipstick by unscrewing it from the tube. Insert the new Cummins 3642469 Dipstick into the tube, ensuring it is fully seated. Secure it in place according to the manufacturer’s instructions, which may involve tightening a retaining clip or screw. Finally, verify the installation by checking that the dipstick moves freely within the tube and that the markings are visible and legible.

Maintenance Tips

To ensure the longevity and accuracy of the Cummins 3642469 Dipstick, regular maintenance is recommended. This includes cleaning the dipstick after each use to remove any oil residue, which can affect readability. Inspect the dipstick for signs of wear or damage, such as bent or corroded sections, and replace it if necessary. Additionally, ensure the dipstick tube is free from obstructions and that the sealing mechanism is intact to prevent oil leaks.

Troubleshooting Common Issues

Common issues with dipsticks include inaccurate readings and physical damage. Inaccurate readings may be due to a bent dipstick or incorrect installation. Straighten the dipstick if bent, or reinstall it according to the manufacturer’s guidelines. Physical damage, such as cracks or corrosion, may require replacement of the dipstick to ensure accurate oil level measurements and prevent potential engine damage.

Role in Preventive Maintenance

Regular use of the Cummins 3642469 Dipstick is a key component of a preventive maintenance strategy for commercial trucks. By ensuring that engine oil levels are consistently monitored and maintained, operators can prevent issues such as oil starvation or overfilling, both of which can lead to engine wear or damage. This proactive approach to maintenance helps extend the life of the engine and reduces the likelihood of unexpected breakdowns.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history dating back to 1919, Cummins has established itself as a trusted name in the commercial truck industry, known for its innovative products and commitment to customer success. The company’s extensive portfolio of parts and services supports the efficient and reliable operation of commercial vehicles worldwide.

Compatibility with Specific Engine Models

The Cummins part 3642469, a Dipstick, is designed to be compatible with several specific engine models. This part is integral for maintaining the engine’s oil levels, ensuring optimal performance and longevity.

For the QSK60 CM500 and QSK60 CM850 MCRS engines, the Dipstick is engineered to fit seamlessly into the engine’s oil system. It allows for easy and accurate measurement of the oil level, which is crucial for the engine’s health. The design of the Dipstick ensures it can be easily inserted and removed, providing a clear view of the oil level.

The compatibility of the Dipstick with these engines is a result of meticulous engineering and testing by Cummins. This ensures that the Dipstick not only fits perfectly but also functions reliably under various operating conditions. The precision in its design is crucial for the accurate assessment of oil levels, which is a fundamental aspect of engine maintenance.

Role of Part 3642469 Dipstick in Engine Systems

The part 3642469 dipstick is a component in the engine system, primarily interacting with the oil level gauge and its location.

Interaction with Oil Level Gauge

The dipstick serves as a direct interface between the oil reservoir and the oil level gauge. When inserted into the engine, it provides a physical measurement of the oil level, which is then translated into a readable format by the oil level gauge. This interaction ensures that the gauge displays an accurate representation of the current oil level within the engine.

Importance of Oil Level Gauge Location

The location of the oil level gauge is strategically chosen to offer convenient access for regular checks. The dipstick, when properly positioned, allows for easy insertion and removal, facilitating routine maintenance. This accessibility is vital for ensuring that the oil level is consistently monitored, thereby preventing potential engine damage due to low oil levels.

Overall Functionality

In summary, the part 3642469 dipstick plays a significant role in maintaining the integrity of the engine system by ensuring that the oil level is accurately measured and regularly monitored. Its design and placement are optimized to work seamlessly with the oil level gauge, contributing to the overall efficiency and reliability of the engine.

Conclusion

The Cummins 3642469 Dipstick is a vital component for maintaining engine oil levels in commercial trucks. Its accurate measurement capabilities, durable construction, and ease of use make it an essential tool for routine maintenance and preventive strategies. By ensuring that engine oil levels are consistently monitored and maintained, operators can significantly extend the life of the engine and reduce the likelihood of unexpected breakdowns.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.