This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

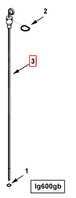

Understanding The Cummins 3649997 Dipstick: A Comprehensive Guide For Commercial Truck Professionals

Introduction To The Cummins 3649997 Dipstick

Overview Of Cummins 3649997 Dipstick

The Cummins 3649997 dipstick is a critical component in the maintenance regimen of commercial truck engines. As a leading manufacturer of diesel engines and related components, Cummins has established a reputation for producing reliable and high-quality parts. This Cummins part plays a vital role in ensuring the engine’s lubrication system functions correctly 1.

Basic Concepts Of A Dipstick

A dipstick is a simple yet essential tool used in engine maintenance to measure the level of oil within the engine. It consists of a long, slender metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil reservoir. By pulling out the dipstick and examining the oil level marked on it, mechanics can ensure that the engine has sufficient lubrication, which is crucial for its operation and longevity 2.

The Role Of The Cummins 3649997 Dipstick In Truck Operations

Purpose And Importance

The Cummins 3649997 dipstick is instrumental in maintaining the health of commercial truck engines. Regular checks using this dipstick allow mechanics to monitor oil levels, ensuring that the engine remains properly lubricated. This is vital for preventing wear and tear, reducing the risk of engine damage, and enhancing the engine’s overall performance and longevity 3.

Operational Insights

Using the Cummins 3649997 dipstick helps prevent engine damage by ensuring that oil levels are maintained within the recommended range. Proper lubrication is essential for reducing friction between moving parts, dissipating heat, and carrying away contaminants. Consistent use of the dipstick in maintenance routines can significantly impact engine performance and longevity.

Troubleshooting And Maintenance Tips

Common Issues And Solutions

Mechanics may encounter several issues with the Cummins 3649997 dipstick, such as inaccurate readings or difficulty in insertion. These problems can often be traced back to contamination, wear, or incorrect usage. A step-by-step troubleshooting guide can help identify and resolve these issues, ensuring accurate oil level readings and maintaining engine health.

Maintenance Best Practices

To ensure the Cummins 3649997 dipstick functions correctly, it is essential to follow recommended maintenance procedures. This includes regular cleaning of the dipstick to remove any oil residue or contaminants, proper reinsertion after checks, and periodic inspection for signs of wear or damage. These practices help ensure accurate oil level readings and prevent potential engine issues.

Expert Insights And Best Practices

Industry Standards And Recommendations

Industry standards for using dipsticks in commercial truck engines emphasize the importance of regular checks and accurate readings. Best practices recommended by experts include using the dipstick as part of a routine maintenance schedule, ensuring the engine is on level ground during checks, and allowing the engine to cool before taking readings to avoid inaccuracies.

Cummins’ Commitment To Quality

Cummins is renowned for its commitment to producing high-quality engine components. The engineering and manufacturing processes behind the Cummins 3649997 dipstick ensure its reliability and performance. This commitment to quality is a testament to Cummins’ dedication to providing durable and efficient solutions for commercial truck engines.

Educational Value For Commercial Truck Professionals

Empowering Engineers And Mechanics

Understanding the Cummins 3649997 dipstick enhances the technical knowledge and skills of engineers and mechanics. Proper maintenance and troubleshooting using this dipstick are crucial for ensuring optimal engine performance, reducing the risk of costly repairs, and extending the engine’s lifespan.

Benefits For Truck Drivers And Fleet Operators

Knowledge of the Cummins 3649997 dipstick contributes to efficient fleet management by enabling truck drivers and fleet operators to maintain their vehicles more effectively. Proper maintenance using the dipstick can reduce downtime, improve overall fleet performance, and enhance safety on the road.

Conclusion

This guide provides a comprehensive understanding of the Cummins 3649997 dipstick, its role in commercial truck engines, and best practices for maintenance and troubleshooting. By leveraging the expertise and insights presented here, commercial truck professionals can enhance their knowledge and skills, ultimately contributing to safer and more efficient truck operations.

Cummins Dipstick Part 3649997 Compatibility

The Cummins dipstick part number 3649997 is designed to fit a range of Cummins engines, ensuring accurate oil level checks and maintenance. This dipstick is compatible with several models, including:

- K38

- K50

- QSK50 CM2150

- K107

- QSK50 CM2150 MCRS

- QSK60 CM850 MCRS

For the engines QSK50 CM2150 and QSK50 CM2150 MCRS, the dipstick is engineered to provide precise measurements, facilitating effective engine maintenance. Similarly, for the QSK60 CM850 MCRS, the dipstick ensures that oil levels are monitored correctly, which is crucial for the engine’s longevity and performance.

The dipstick’s design accommodates the specific requirements of these engines, ensuring a secure fit and reliable readings. This compatibility is essential for maintaining the operational integrity of the engines, as proper oil level management is critical for their performance and durability.

Role of Part 3649997 Dipstick in Engine Systems

The part 3649997 dipstick is an essential component in the operation and maintenance of engine systems, particularly in relation to the oil level gauge. This dipstick serves as a direct interface between the engine’s lubrication system and the monitoring mechanisms that ensure optimal engine performance.

Interaction with the Oil Level Gauge

The dipstick is inserted into the engine’s oil filler neck, allowing it to come into direct contact with the engine oil. When the dipstick is removed and examined, the oil level can be visually assessed against the markings on the dipstick. These markings correspond to the minimum and maximum oil levels required for the engine’s efficient operation.

The oil level gauge, often a simple mechanical indicator or a more advanced electronic sensor, relies on the information provided by the dipstick. In mechanical systems, the dipstick’s markings are directly read by the operator. In electronic systems, the dipstick may be coupled with sensors that translate the oil level into an electronic signal, which is then displayed on the vehicle’s dashboard.

Ensuring Accurate Oil Level Readings

Accurate oil level readings are vital for the engine’s lubrication system. The dipstick ensures that the oil level is maintained within the specified range, preventing both overfilling and underfilling. Overfilling can lead to oil aeration and foam formation, which reduces the oil’s lubricating properties and can cause damage to engine components. Underfilling, on the other hand, can result in insufficient lubrication, leading to increased friction, wear, and potential engine failure.

Maintenance and Diagnostic Role

Beyond routine checks, the dipstick plays a role in maintenance and diagnostics. By regularly checking the oil level with the dipstick, mechanics can identify trends such as gradual oil loss, which may indicate a leak or excessive consumption. The condition of the oil on the dipstick can also provide insights into the engine’s health; for example, milky oil may suggest a coolant leak, while dark, gritty oil could indicate the need for an oil change or further investigation into engine wear.

In summary, the part 3649997 dipstick is integral to the engine system, facilitating accurate oil level measurements and contributing to the overall maintenance and diagnostic processes. Its interaction with the oil level gauge ensures that the engine remains properly lubricated, thereby enhancing performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.