This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

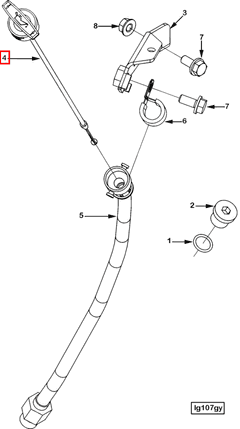

The Cummins 3684296 Dipstick is a specialized component designed for use in commercial trucks. Its primary function is to facilitate the measurement and monitoring of engine oil levels, ensuring that the engine operates within optimal parameters. This part is integral to the maintenance and operational efficiency of truck engines, providing a straightforward yet effective means for technicians and operators to gauge oil levels and maintain engine health 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet vital tool used in internal combustion engines to measure the level of engine oil. It consists of a long, thin metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil sump. When removed, the oil level can be read from the markings on the dipstick, indicating whether the oil level is within the acceptable range. Regular checking of the oil level is crucial for engine maintenance, as it helps prevent oil starvation, which can lead to engine damage, and ensures that the oil is changed at appropriate intervals to maintain lubrication and cooling efficiency 2.

Purpose of the Cummins 3684296 Dipstick

This Cummins part plays a specific role in the operation and maintenance of truck engines by providing an accurate means to check the engine oil level. This is particularly important in commercial trucks, where engine performance and reliability are paramount. By ensuring that the oil level is correct, the dipstick helps maintain the engine’s lubrication system, which is essential for reducing friction, wear, and heat within the engine components 3.

Key Features

The Cummins 3684296 Dipstick is designed with several key features to enhance its functionality and durability. It is constructed from high-quality materials to withstand the harsh conditions within a truck engine. The dipstick is marked with clear, easy-to-read indicators for the minimum and maximum oil levels, facilitating accurate measurements. Additionally, its design ensures a secure fit within the engine, preventing oil leaks and ensuring reliable readings.

Benefits

Using the Cummins 3684296 Dipstick offers several benefits. Its accurate measurement capabilities help ensure that the engine oil level is maintained within the optimal range, contributing to engine longevity and performance. The dipstick’s durable construction means it can withstand the rigors of commercial truck operation, providing reliable service over time. Furthermore, its ease of use makes it a practical tool for routine maintenance checks, allowing for quick and efficient oil level assessments.

Installation and Usage

Proper installation and usage of the Cummins 3684296 Dipstick are crucial for accurate oil level readings. To install, ensure the engine is turned off and has had sufficient time to cool. Locate the dipstick tube, usually found near the engine’s center, and remove the dipstick by pulling it straight out. Wipe it clean with a lint-free cloth, reinsert it fully, and then remove it again to check the oil level against the markings. For an accurate reading, ensure the dipstick is reinserted and removed correctly each time.

Maintenance Tips

To ensure the longevity and accuracy of the Cummins 3684296 Dipstick, regular maintenance is recommended. After each use, wipe the dipstick clean to remove any oil residue, which can affect the accuracy of future readings. Inspect the dipstick regularly for signs of wear or damage, such as bending or corrosion, and replace it if necessary. Additionally, ensure the dipstick tube is free from debris and that the cap is securely fastened to prevent oil leaks.

Troubleshooting Common Issues

Common issues with dipsticks include inaccurate readings, oil leaks around the dipstick tube, and difficulty in removing or inserting the dipstick. Inaccurate readings may be due to a bent or damaged dipstick, requiring replacement. Oil leaks can often be resolved by ensuring the dipstick is fully seated and the cap is tightly secured. If the dipstick is difficult to remove or insert, check for obstructions within the tube and clean as necessary.

Safety Considerations

When using the Cummins 3684296 Dipstick, it is important to follow safety practices to prevent injury and ensure accurate readings. Always allow the engine to cool before checking the oil level to avoid burns from hot engine components or oil. Use a lint-free cloth to handle the dipstick to prevent contamination and ensure accurate readings. Store the dipstick in a clean, dry place when not in use to maintain its condition.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry, providing reliable and efficient engine solutions. The company’s commitment to innovation and quality is reflected in its wide range of products, including the Cummins 3684296 Dipstick, designed to meet the demanding requirements of commercial truck engines 4.

Cummins Engine Dipstick 3684296 Compatibility

The Cummins Dipstick part number 3684296 is designed to be compatible with several Cummins engine models. This dipstick is an essential component for checking the oil level in the engine, ensuring that the engine operates smoothly and efficiently.

ISX CM871

The ISX CM871 engine is one of the models that can utilize the Cummins Dipstick part number 3684296. This engine is known for its robust performance and reliability, making it a popular choice in various applications. The dipstick ensures that the oil level is maintained at the correct level, preventing potential engine damage due to low oil.

Group Compatibility

The Cummins Dipstick part number 3684296 is also compatible with other engines within the same group as the ISX CM871. This compatibility ensures that the dipstick can be used across multiple engine models, providing a standardized solution for oil level checks. The design and specifications of the dipstick are tailored to fit seamlessly with these engines, ensuring accurate readings and ease of use.

By using the Cummins Dipstick part number 3684296, technicians and operators can confidently monitor the oil levels in these engines, contributing to the overall maintenance and longevity of the equipment.

Role of Part 3684296 Dipstick in Engine Systems

Part 3684296 Dipstick is an essential component in maintaining the operational integrity of various engine systems. Its primary function is to provide a means for checking the oil level within the engine, ensuring that it remains within the optimal range for efficient performance and longevity.

Integration with Oil Level Gauge

The Dipstick works in conjunction with the Oil Level Gauge to offer a visual and sometimes tactile indication of the oil level. When inserted into the engine’s oil filler neck, the Dipstick allows the user to pull it out and check the oil level by observing the markings on the Dipstick. This data is then often correlated with the Oil Level Gauge, which may provide a more precise reading through mechanical or electronic means.

Contribution to Engine Maintenance

Regular use of the Dipstick in checking the oil level helps in identifying potential issues such as oil leaks or excessive oil consumption. This proactive approach allows for timely maintenance, preventing more severe engine damage. The Dipstick also aids in ensuring that the engine is not operating with either too much or too little oil, both of which can lead to inefficient performance and increased wear on engine components.

Support for Diagnostic Processes

In diagnostic scenarios, the Dipstick serves as a quick reference point for the condition of the engine oil. The color and consistency of the oil on the Dipstick can offer insights into the engine’s health. For instance, dark or gritty oil may indicate the need for an oil change, while milky oil could suggest a coolant leak into the engine.

Facilitation of Oil Changes

During oil changes, the Dipstick is instrumental in draining the old oil from the engine. By removing the Dipstick and opening the oil drain plug, mechanics can ensure a complete and efficient oil change, contributing to the engine’s overall cleanliness and performance.

Enhancement of User Confidence

For users who perform regular maintenance checks, the Dipstick offers a simple yet effective way to engage with their engine’s health. This empowerment fosters a deeper understanding and appreciation of the engine’s needs, leading to more informed decision-making regarding maintenance and repairs.

Conclusion

The Cummins 3684296 Dipstick is a critical component in the maintenance and operation of commercial truck engines. Its accurate measurement capabilities, durable construction, and ease of use make it an indispensable tool for ensuring engine health and longevity. By following proper installation, usage, and maintenance practices, technicians and operators can leverage this part to perform timely maintenance checks, prevent engine damage, and enhance overall engine performance.

-

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ -

Peters, George, and Barbara J Peters. Automobile Vehicle Safety. CRC Press, 2002.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5579756, D4.5 CM2620 D104B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.