This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

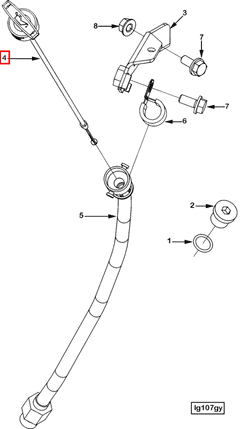

The Cummins 3684297 Dipstick is a specialized component designed for use in heavy-duty trucks. It plays a role in the maintenance and operation of these vehicles by allowing for the accurate measurement of engine oil levels. Ensuring the correct oil level is maintained is fundamental to the efficient operation and longevity of the engine 1.

Basic Concepts of a Dipstick

A dipstick is a tool used in internal combustion engines to measure the level of lubricating oil. It consists of a long, thin metal or plastic rod with graduated markings. When inserted into the engine’s oil sump and then withdrawn, the oil level can be read from the markings on the dipstick. This process allows for the assessment of whether the oil level is within the manufacturer’s specified range, ensuring that engine components receive adequate lubrication 2.

Purpose of the Cummins 3684297 Dipstick

This Cummins part facilitates the measurement of oil levels within the engine. Proper lubrication is necessary for the smooth operation of engine components, reducing friction and wear. By providing an accurate reading of the oil level, this dipstick helps ensure that the engine remains well-lubricated, contributing to its overall performance and longevity 3.

Key Features

The Cummins 3684297 Dipstick is characterized by its robust design and the use of high-quality materials, which enhance its performance and durability. It is crafted to withstand the harsh conditions within a heavy-duty truck engine. The dipstick features clear, easy-to-read markings for accurate oil level measurement and is designed for straightforward installation and use.

Benefits

Utilizing the Cummins 3684297 Dipstick offers several advantages. Its design ensures accurate oil level measurement, which is vital for maintaining engine health. The ease of use associated with this dipstick simplifies the process of checking oil levels, making it a practical tool for regular maintenance routines. Additionally, by ensuring proper oil levels, the dipstick contributes to the longevity of the engine.

Installation and Usage

To install and use the Cummins 3684297 Dipstick, follow these steps: First, ensure the truck is on a level surface and the engine is off. Locate the dipstick tube, usually found near the engine’s center. Pull out the dipstick, wipe it clean with a lint-free cloth, reinsert it fully, and then pull it out again to check the oil level. The oil should be between the minimum and maximum marks. If necessary, add oil to reach the correct level.

Troubleshooting and Maintenance

Common issues with dipsticks include inaccurate readings due to contamination or damage. To troubleshoot, ensure the dipstick is clean and undamaged. Regular maintenance involves checking the dipstick for wear and ensuring it is securely fitted in its tube. Keeping the dipstick and its tube clean will help maintain accurate readings and the dipstick’s longevity.

Safety Considerations

When using the Cummins 3684297 Dipstick to check oil levels, it is important to observe safety guidelines. Ensure the engine is cool to avoid burns from hot components. Use caution when handling the dipstick to prevent injury. Additionally, be aware of the oil’s condition; if it appears contaminated or has an unusual color, it may indicate engine issues that require further investigation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to quality and innovation in diesel engine technology and related components. The company’s extensive product line and global presence underscore its role as a leading manufacturer in the industry.

Role of Part 3684297 Dipstick in Engine Systems

This part is an integral component in the maintenance and operation of engine systems, working in conjunction with the oil level gauge to ensure optimal performance and longevity of the engine.

Interaction with the Oil Level Gauge

The dipstick interfaces directly with the oil level gauge system. When inserted into the engine’s oil filler tube, the dipstick provides a physical measurement of the oil level. This data is then visually interpreted by the oil level gauge, which may be a simple mechanical indicator or a more advanced electronic sensor. The accurate reading obtained from the dipstick allows the oil level gauge to display the current state of the engine’s lubrication system, enabling timely top-ups or changes as necessary.

Ensuring Proper Lubrication

By offering a precise measurement of the oil level, the dipstick helps maintain the engine’s lubrication system. Proper lubrication is vital for reducing friction between moving parts, dissipating heat, and carrying away contaminants. The dipstick’s role in this process cannot be overstated, as it ensures that the engine operates within safe parameters, thereby prolonging its operational life and enhancing efficiency.

Facilitating Regular Maintenance

Regular checks using the dipstick are a fundamental part of routine engine maintenance. Mechanics and engineers rely on the dipstick to perform quick assessments of the oil level during service intervals. This proactive approach helps identify potential issues before they escalate into more significant problems, such as engine wear or failure.

Integration with Engine Management Systems

In modern engines, the dipstick may also interact with more complex engine management systems. Some advanced systems use the data from the dipstick to trigger alerts or notifications when the oil level falls below a predetermined threshold. This integration enhances the overall monitoring capabilities of the engine, allowing for more precise control and maintenance.

Supporting Diagnostic Processes

During diagnostic procedures, the dipstick serves as a quick reference point for assessing the engine’s condition. Abnormal oil levels detected via the dipstick can indicate issues such as oil leaks, consumption, or contamination. This initial data point can guide further diagnostic efforts, helping engineers and mechanics pinpoint the root cause of any engine-related problems.

Conclusion

In summary, the Cummins 3684297 Dipstick plays a significant role in the efficient and effective operation of engine systems. Its interaction with the oil level gauge and other components ensures that the engine remains well-lubricated, maintained, and monitored, contributing to overall engine health and performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.