This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

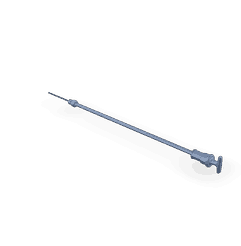

The Cummins 3692947 Dipstick is a component designed for use in commercial trucks. It serves a specific function within the engine system, facilitating the monitoring of engine oil levels. This monitoring is vital for ensuring the engine operates within optimal parameters, thereby contributing to the overall efficiency and longevity of the vehicle 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in engine maintenance. It consists of a long, thin metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil reservoir. The primary function of a dipstick is to provide a means of checking the oil level within the engine. By withdrawing the dipstick and observing the oil level marked on it, mechanics and operators can determine if the oil level is within the acceptable range. This process is fundamental to maintaining proper lubrication, which is essential for the engine’s moving parts to function smoothly and efficiently 2.

Purpose of the Cummins 3692947 Dipstick

The Cummins 3692947 Dipstick plays a role in monitoring engine oil levels and ensuring proper lubrication. Specifically designed for Cummins engines, this dipstick allows for accurate measurement of the oil level, which is critical for the engine’s performance and longevity. By providing a clear indication of the oil level, it enables timely top-ups or changes, thereby preventing engine damage due to insufficient lubrication 3.

Key Features

The Cummins 3692947 Dipstick is characterized by several key features that enhance its functionality. It is constructed from high-quality materials to ensure durability and accuracy in readings. The design includes clear markings for oil level indicators, making it easy to read and interpret. Additionally, the dipstick is tailored to fit snugly within Cummins engines, ensuring a secure and leak-free connection.

Benefits

Utilizing the Cummins 3692947 Dipstick offers several advantages. Its design contributes to improved accuracy in oil level readings, which is vital for maintaining engine health. The materials used in its construction ensure durability, allowing it to withstand the harsh conditions within an engine environment. Furthermore, its ease of use makes it a practical tool for both professional mechanics and vehicle operators.

Installation Process

Installing the Cummins 3692947 Dipstick requires careful attention to ensure proper function and safety. The process involves locating the oil filler cap on the engine, removing it, and inserting the dipstick into the designated tube until it reaches the bottom. Once fully inserted, it should be withdrawn to check the oil level. Tools required may include a socket wrench for removing the oil filler cap. Safety precautions include ensuring the engine is cool before attempting installation and wearing protective gloves to avoid burns or injuries.

Maintenance Tips

To ensure the longevity and accurate readings of the Cummins 3692947 Dipstick, regular maintenance is recommended. This includes cleaning the dipstick after each use to remove any oil residue, which can affect the accuracy of future readings. Inspection for any signs of wear or damage is also important, as a compromised dipstick may not provide reliable readings. Keeping the dipstick free from contaminants and storing it in a clean, dry place when not in use will help maintain its condition.

Troubleshooting Common Issues

Common issues with dipsticks, such as inaccurate readings or physical damage, can often be resolved with simple solutions. Inaccurate readings may be due to a dirty dipstick, which can be rectified by cleaning it thoroughly. Physical damage, such as bends or cracks, may require replacement of the dipstick to ensure accurate readings and prevent oil leaks.

Role in Preventive Maintenance

Incorporating the use of the Cummins 3692947 Dipstick into a preventive maintenance program is beneficial for commercial trucks. Regular checks of the oil level using this dipstick allow for timely identification of low oil levels or contamination, enabling prompt action to be taken. This practice contributes to the overall health and efficiency of the engine, reducing the risk of unexpected breakdowns and extending the vehicle’s operational life.

Cummins Overview

Cummins Inc. has a long-standing reputation in the automotive industry for producing high-quality, reliable engines and components. Founded in 1919, the company has grown to become a global leader in engine manufacturing, with a strong focus on innovation, quality, and customer satisfaction. Cummins’ contributions to the industry include advancements in engine technology and a commitment to sustainability, making them a trusted name in commercial vehicle applications.

Cummins Dipstick Part 3692947 Compatibility

The Cummins part number 3692947, which is a Dipstick, is designed to fit seamlessly with several engine models. This dipstick is engineered to provide accurate oil level readings, ensuring optimal engine performance and longevity. Below are the specific engine models that this dipstick is compatible with:

- X15 CM2350 X116B

- X15 CM2450 X134B

These engines are part of the Cummins lineup, and the dipstick is crafted to integrate smoothly with their design specifications. It ensures that users can easily check and maintain the correct oil levels, which is crucial for the engine’s health and efficiency.

Role of Part 3692947 Dipstick in Engine Systems

The part 3692947 dipstick is an essential component in the accurate measurement and monitoring of the oil level within an engine system. It works in conjunction with the oil gauge to provide real-time data on the engine’s lubrication status.

Interaction with the Oil Gauge

The dipstick is directly involved in the operation of the oil gauge. When the dipstick is inserted into the engine’s oil sump, it collects a sample of the oil. Upon removal, the oil level can be visually assessed by observing the markings on the dipstick. This information is then used to inform the oil gauge, which displays the oil level to the operator.

Ensuring Proper Oil Level

Maintaining the correct oil level is important for the engine’s performance and longevity. The dipstick allows for periodic checks to ensure that the oil level remains within the manufacturer’s specified range. If the oil level is too low, it can lead to inadequate lubrication, increased friction, and potential engine damage. Conversely, if the oil level is too high, it can cause foaming, which reduces the oil’s effectiveness and can lead to engine issues.

Facilitating Oil Changes

During an oil change, the dipstick is used to verify that the new oil has been properly added to the engine. After the old oil is drained and the oil filter is replaced, the new oil is poured into the engine. The dipstick is then used to check the oil level, ensuring that the correct amount of new oil has been added.

Supporting Diagnostic Procedures

In diagnostic procedures, the dipstick can provide valuable information about the engine’s condition. The color and consistency of the oil on the dipstick can indicate the presence of contaminants, such as metal particles or fuel, which may suggest internal engine wear or issues.

Integration with Engine Systems

The dipstick is a simple yet effective tool that integrates seamlessly with the engine’s oil system. It allows for easy and quick assessments of the oil level, which is a fundamental aspect of engine maintenance and operation. By providing accurate and timely information, the dipstick supports the overall health and efficiency of the engine system.

Conclusion

The Cummins 3692947 Dipstick is a vital component in the maintenance and operation of Cummins engines. Its role in monitoring oil levels ensures that engines operate efficiently and with longevity. By understanding its features, benefits, and proper use, vehicle operators and mechanics can maintain optimal engine performance and prevent potential issues related to oil levels.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.