This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

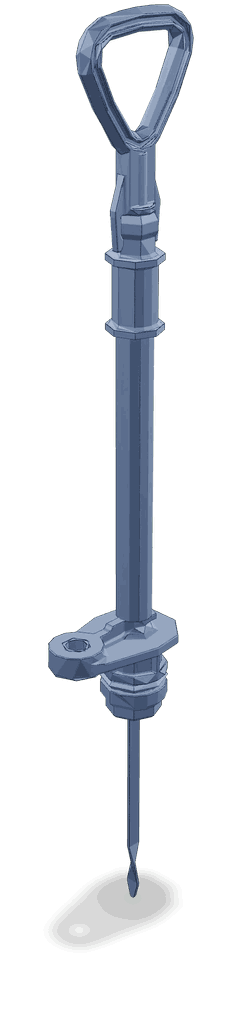

The Cummins 3697520 Dipstick is a specialized component designed for use in heavy-duty trucks. Its purpose is to facilitate the measurement of oil levels within the engine, ensuring that the engine operates within optimal lubrication parameters. This part is significant in the maintenance routine of heavy-duty trucks, as it allows for regular checks and adjustments of oil levels, which are vital for the longevity and performance of the engine 3.

Basic Concepts of a Dipstick

A dipstick is a tool used in engines to measure the level of lubricant, typically oil. It consists of a long, thin metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil sump. The dipstick operates on the principle of capillary action, where oil rises along the dipstick to a certain level, indicating the amount of oil present in the sump. The markings on the dipstick provide a visual reference for the oil level, allowing for easy assessment by the user 4.

Purpose of the Cummins 3697520 Dipstick

This Cummins part plays a role in the operation of a truck by enabling the measurement of oil levels and ensuring proper lubrication of engine components. Adequate lubrication is necessary to reduce friction between moving parts, dissipate heat, and prevent wear and tear. By providing accurate oil level readings, this dipstick helps maintain the engine’s efficiency and longevity 1.

Key Features

The Cummins 3697520 Dipstick incorporates several design elements and materials that enhance its durability and accuracy. It is constructed from high-grade steel, which offers resistance to corrosion and physical damage. The dipstick features precise measurement markings, allowing for accurate assessment of oil levels. Additionally, its design ensures a snug fit within the engine, preventing oil leaks and ensuring reliable readings 2.

Benefits

Using the Cummins 3697520 Dipstick offers several advantages. It contributes to improved engine performance by ensuring that the engine operates with the correct amount of lubrication. This, in turn, can extend the engine’s life by reducing wear on critical components. Furthermore, the dipstick simplifies maintenance procedures, allowing for quick and easy oil level checks, which can help prevent engine damage due to low oil levels 3.

Installation Process

To install the Cummins 3697520 Dipstick, first, ensure the engine is turned off and has cooled down. Locate the dipstick tube, usually found near the top of the engine. Remove the old dipstick by pulling it straight out of the tube. Insert the new dipstick fully into the tube until it stops, then withdraw it slightly to ensure it is seated correctly. Push it back in fully and secure the cap if applicable. This ensures the dipstick is correctly positioned and can provide accurate readings 4.

Troubleshooting Common Issues

Frequent problems associated with dipsticks include inaccurate readings or physical damage. Inaccurate readings may result from a misaligned dipstick or contamination on the dipstick surface. To address this, ensure the dipstick is fully seated and clean it with a lint-free cloth before taking a reading. Physical damage, such as bends or cracks, may require replacement of the dipstick to ensure accurate measurements and prevent oil leaks 1.

Maintenance Tips

Regular maintenance of the Cummins 3697520 Dipstick involves cleaning it after each use to remove any oil residue and contaminants. Inspect the dipstick for signs of wear or damage, such as bends or cracks, and replace it if necessary. Additionally, ensure the dipstick tube is free from debris and that the cap (if present) is securely fastened to prevent oil leaks 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. Founded in 1919, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company’s product range includes engines, filtration, emissions solutions, and power generation equipment, serving various markets such as heavy-duty trucking, construction, agriculture, and power generation. Cummins is recognized for its commitment to sustainability and technological advancement, making it a trusted name in the production of diesel engines and related components 3.

Cummins Dipstick Part 3697520 Compatibility

The Cummins dipstick part number 3697520 is designed to fit a range of engine models, ensuring accurate oil level readings and maintenance. Here is a detailed overview of its compatibility with the specified engines:

ISG11 CM2880 G108 and ISG12 CM2880 G107

The dipstick part 3697520 is compatible with the ISG11 CM2880 G108 and ISG12 CM2880 G107 engines. These engines are part of the Cummins lineup known for their robust performance and reliability. The dipstick ensures precise oil level monitoring, which is crucial for maintaining engine health and performance 4.

QSG12/X12 CM2350 G110

For the QSG12/X12 CM2350 G110 engine, the dipstick part 3697520 is specifically engineered to fit the engine’s design. This compatibility ensures that users can easily check oil levels, contributing to the engine’s longevity and efficiency 1.

X11 CM2670 X126B and X12 CM2350 X119B

The dipstick part 3697520 is also suitable for the X11 CM2670 X126B and X12 CM2350 X119B engines. These engines benefit from the dipstick’s design, which allows for straightforward oil level checks, aiding in the maintenance and operational efficiency of the engines 2.

X12 CM2670 X121B and X13 CM2670 X122B

Lastly, the dipstick part 3697520 fits the X12 CM2670 X121B and X13 CM2670 X122B engines. These engines are part of a series known for their durability and performance. The dipstick ensures that users can accurately monitor oil levels, which is essential for the engines’ maintenance and optimal operation 3.

By providing accurate oil level readings, the Cummins dipstick part 3697520 ensures that these engines run smoothly and efficiently, contributing to their overall performance and longevity.

Role of Part 3697520 Dipstick in Engine Systems

This part is an essential component in the maintenance and monitoring of engine systems. It facilitates the accurate measurement of the oil level within the engine, ensuring that the lubrication system operates efficiently.

When the dipstick is inserted into the oil filler tube and then withdrawn, the oil level can be read directly from the markings on the dipstick. This reading is then compared against the manufacturer’s specified range to determine if the oil level is adequate.

The dipstick also interacts with the oil level gauge, which may be a simple mechanical indicator or a more complex electronic system. In mechanical systems, the gauge relies on the physical position of the dipstick to provide a visual indication of the oil level. In electronic systems, sensors may be integrated with the dipstick to provide real-time data to the engine control unit (ECU), allowing for more precise monitoring and alerting the operator to any discrepancies in oil levels.

Regular use of the dipstick in checking the oil level helps prevent engine wear by ensuring that there is always sufficient lubrication. It also aids in the early detection of oil leaks or consumption, allowing for timely maintenance and reducing the risk of engine damage 4.

Conclusion

The Cummins 3697520 Dipstick is a critical component for maintaining the health and performance of heavy-duty truck engines. By ensuring accurate oil level measurements, it contributes to the efficient operation of the lubrication system, thereby extending engine life and enhancing performance. Regular maintenance and proper use of this part are essential for the optimal functioning of heavy-duty engines.

-

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ ↩ ↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ ↩ ↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ ↩ ↩ ↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.