This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

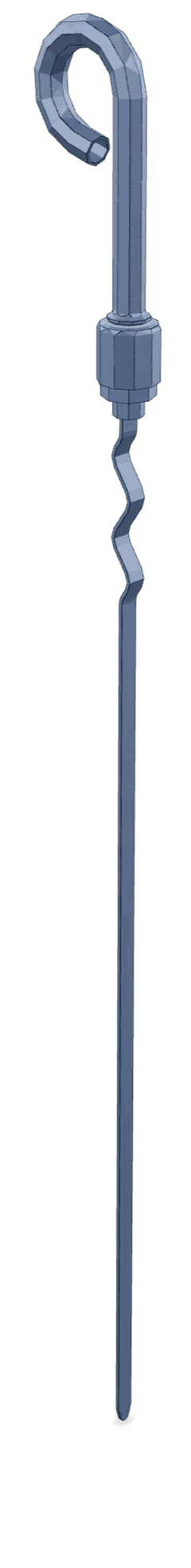

The Cummins 3904288 Dipstick is a component designed for use in commercial trucks, specifically for monitoring engine oil levels. Its role in the maintenance routine of these vehicles is significant, as it allows for the accurate assessment of oil levels, which is vital for the engine’s performance and longevity 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in engines to measure the level of fluid, typically oil. It consists of a long, thin metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil sump. The dipstick has markings that indicate the minimum and maximum oil levels. When pulled out, the oil level can be read against these markings, providing a quick and effective way to monitor the engine’s lubrication system 2.

Purpose of the Cummins 3904288 Dipstick

This Cummins part is specifically engineered for use in commercial trucks equipped with Cummins engines. It plays a role in the operation and maintenance of these vehicles by allowing technicians and operators to check the oil level within the engine. Proper oil levels are necessary for the engine’s lubrication system to function correctly, reducing wear on moving parts and ensuring efficient operation.

Key Features

The 3904288 is characterized by its robust design and the use of high-quality materials, ensuring durability and reliability in demanding commercial truck environments. Its design includes precise markings for oil level indication and a secure fitting to prevent oil leaks. Additionally, the dipstick may feature a temperature sensing bulb at the end, which, when combined with a temperature gauge, allows for the monitoring of oil temperature, providing further insight into the engine’s condition.

Benefits

Utilizing this part offers several advantages. Its design ensures accurate measurement of oil levels, which is crucial for maintaining engine health. The durability of the dipstick means it can withstand the rigors of commercial truck use, reducing the need for frequent replacements. Furthermore, its ease of use allows for quick checks, minimizing downtime during maintenance routines.

Installation Process

Installing the 3904288 involves a few straightforward steps to ensure it is correctly positioned for optimal performance. First, the old dipstick, if present, should be removed. The new dipstick is then inserted into the dipstick tube until it reaches the bottom, ensuring a secure fit. It is then withdrawn slightly to the designated full mark before being fully seated. This process ensures the dipstick is correctly aligned and can provide accurate readings.

Regular Maintenance Practices

To ensure the longevity and accuracy of the 3904288, regular maintenance practices are recommended. This includes cleaning the dipstick after each use to remove any oil residue, which can affect the accuracy of readings. Additionally, inspecting the dipstick for any signs of wear or damage is important, as this can impact its effectiveness. Regular maintenance of the dipstick contributes to the overall efficiency and reliability of the engine.

Troubleshooting Common Issues

Common issues with the 3904288 may include inaccurate readings or physical damage. Inaccurate readings can often be resolved by ensuring the dipstick is correctly installed and cleaned. Physical damage, such as bends or cracks, may require replacement of the dipstick to ensure accurate measurements and prevent oil leaks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is evident in its product line, including the 3904288, which is designed with the reliability and performance that Cummins is known for.

Cummins Engine Dipstick Compatibility

The Cummins part number 3904288 is designed to fit seamlessly with several Cummins engine models. This dipstick is an essential component for checking the oil level in the engine, ensuring that the engine operates smoothly and efficiently.

Engine Compatibility

- 4B3.9 Engine Group

The 3904288 is specifically engineered to fit the 4B3.9 engine series. This engine series is known for its reliability and performance, making it a popular choice in various industrial and commercial applications. The dipstick’s design ensures a precise and easy-to-read oil level measurement, which is crucial for maintaining the engine’s health.

- Other Cummins Engines

While the primary focus is on the 4B3.9 engine, the 3904288 may also be compatible with other Cummins engine models. Cummins has a wide range of engines, and the dipstick’s universal design allows it to fit multiple models within the Cummins engine family. This compatibility ensures that users can easily find the right dipstick for their specific engine needs.

Importance of Proper Fit

Using the correct dipstick for your engine is vital for several reasons:

- Accurate Oil Level Reading: Ensures that the oil level is correctly measured, preventing overfilling or underfilling.

- Engine Performance: Helps maintain optimal engine performance by ensuring the engine is properly lubricated.

- Maintenance Ease: Simplifies the maintenance process, allowing users to quickly and easily check their oil levels.

By ensuring that the 3904288 fits correctly with the 4B3.9 engine and potentially other Cummins engines, users can maintain their engines’ health and performance effectively.

Role of Part 3904288 in Engine Systems

The 3904288 is an essential component in the maintenance and monitoring of engine systems. It works in conjunction with the oil level gauge to ensure the engine operates within optimal parameters.

Interaction with the Oil Level Gauge

The dipstick is directly involved in the process of checking the oil level within the engine. When inserted into the engine’s oil filler tube, it provides a physical means to measure the current oil level. The oil level gauge, often marked on the dipstick itself, allows for a quick visual assessment. This interaction ensures that the oil level remains within the manufacturer’s specified range, promoting efficient lubrication and cooling of engine components.

Ensuring Proper Lubrication

By accurately indicating the oil level, the dipstick helps maintain the necessary lubrication for moving parts within the engine. Insufficient oil can lead to increased friction and wear, while excessive oil can cause foaming and reduced lubrication efficiency. The dipstick’s role in this process is to provide a reliable method for engineers and mechanics to monitor and adjust the oil level as needed.

Facilitating Routine Maintenance

Regular use of the dipstick during maintenance checks allows for the early detection of oil leaks or consumption issues. If the oil level drops significantly between checks, it may indicate a leak or excessive burning of oil, prompting further investigation and necessary repairs. This proactive approach helps in maintaining the engine’s performance and longevity.

Supporting Diagnostic Processes

In diagnostic scenarios, the dipstick can offer insights into the engine’s condition. The color and consistency of the oil on the dipstick can indicate contamination, such as the presence of water or metal particles, which may signal underlying issues within the engine. This information is valuable for making informed decisions about further diagnostic steps or required repairs.

Conclusion

The Cummins 3904288 Dipstick is a vital component in the maintenance and monitoring of commercial truck engines. Its robust design, precise markings, and ease of use make it an indispensable tool for ensuring optimal engine performance and longevity. Regular maintenance and proper use of this part contribute significantly to the overall efficiency and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.