This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

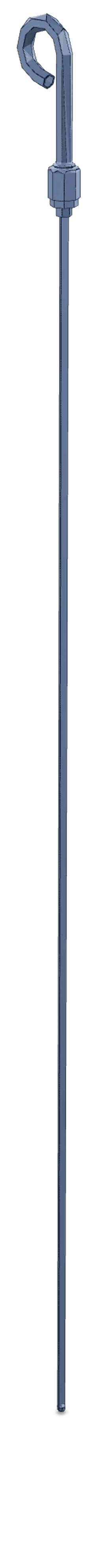

The Cummins 3908314 Dipstick is a specialized component designed for use in Cummins engines, commonly found in commercial trucks. Its primary function is to facilitate the monitoring of engine oil levels, which is a fundamental aspect of routine maintenance. Ensuring the correct oil level is vital for the efficient operation and longevity of the engine. This part is engineered to provide accurate and reliable readings, contributing to the overall maintenance regimen of commercial vehicles 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in internal combustion engines to measure the level of lubricating oil. It consists of a long, slender metal or plastic rod with a handle at one end. The rod is inserted into the engine’s oil sump through a tube. Once inserted and then withdrawn, the oil level can be read from the markings on the dipstick. This process allows for the assessment of whether the oil level is within the manufacturer’s specified range 2.

Purpose of the Cummins 3908314 Dipstick

This Cummins part plays a role in the operation and maintenance of a truck’s engine by enabling the monitoring of oil levels. Proper oil levels are necessary for the lubrication of engine components, reducing friction and wear. The dipstick provides a straightforward method for operators to check the oil level regularly, ensuring that the engine operates within optimal conditions. This regular monitoring helps in identifying potential issues before they escalate into more significant problems 3.

Key Features

The Cummins 3908314 Dipstick is characterized by several design elements and materials that enhance its functionality and durability. It is typically made from high-quality steel, which provides resistance to corrosion and wear. The dipstick features clear and precise markings for easy reading of the oil level. Additionally, it is designed to fit securely into the engine’s oil sump, ensuring accurate measurements and preventing oil leaks.

Benefits

Using the Cummins 3908314 Dipstick offers several advantages. Its design ensures accuracy in oil level measurement, which is critical for maintaining engine health. The ease of use, with clear markings and a sturdy handle, allows for quick and efficient checks. Furthermore, its compatibility with Cummins engines ensures that it meets the specific requirements and standards set by the manufacturer, providing reliability and peace of mind for operators.

Installation and Usage

To install and use the Cummins 3908314 Dipstick, follow these steps:

- Ensure the engine is turned off and has had sufficient time to cool.

- Locate the dipstick tube, typically found on the side of the engine.

- Remove the dipstick by pulling it straight out of the tube.

- Wipe the dipstick clean with a lint-free cloth.

- Reinsert the dipstick fully into the tube and then remove it again to check the oil level.

- Observe the oil level against the markings on the dipstick.

- If necessary, add oil to reach the recommended level, using the type of oil specified by the manufacturer.

Troubleshooting and Maintenance

Common issues with dipsticks may include inaccurate readings due to wear or damage, or oil leaks around the dipstick tube. To address these issues, regularly inspect the dipstick for signs of wear or corrosion. If the dipstick appears damaged, replace it with a new one. Ensure the dipstick is fully seated in the tube to prevent oil leaks. Regular maintenance of the dipstick and adhering to the manufacturer’s guidelines for oil changes and levels will help ensure the longevity and effectiveness of the Cummins 3908314 Dipstick.

Safety Considerations

When using the Cummins 3908314 Dipstick, it is important to follow safety practices to prevent injury and ensure accurate readings. Always allow the engine to cool before checking the oil level to avoid burns from hot surfaces. Wear protective gloves when handling the dipstick to protect your hands from hot engine components. Additionally, be cautious when interpreting the oil condition; contaminated or discolored oil may indicate underlying issues that require further investigation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for quality, reliability, and innovation in the commercial truck industry. The company is committed to advancing technology and providing solutions that meet the evolving needs of its customers, ensuring that their products contribute to the efficiency and performance of commercial vehicles.

Role of Part 3908314 Dipstick in Engine Systems

The part 3908314 dipstick is an essential component in the accurate measurement and monitoring of oil levels within an engine system. It interfaces directly with the oil level gauge to provide real-time data on the oil status, ensuring that the engine operates within optimal parameters.

Interaction with Oil Level Gauge

The dipstick is designed to be inserted into the engine’s oil reservoir. Once in place, it provides a physical means to measure the oil level. When removed, the oil adhering to the dipstick is compared against marked levels, allowing for a quick visual assessment. This data is then relayed to the oil level gauge, which translates the physical measurement into a readable format for the operator.

Ensuring Accurate Oil Level Readings

Accurate oil level readings are vital for the longevity and performance of the engine. The dipstick plays a significant role in this process by offering a consistent and reliable method for oil level checks. It ensures that the oil level gauge receives precise information, allowing for timely oil changes and maintenance, thus preventing potential engine damage due to low oil levels.

Integration with Engine Systems

In modern engine systems, the dipstick may also be part of an automated oil monitoring system. Here, it works in conjunction with sensors that detect the oil level and condition. The data collected by the dipstick is crucial for these systems to function correctly, providing the necessary input for the oil level gauge to display accurate readings and for the engine control unit to make informed decisions regarding oil management.

Maintenance and Inspection

Regular inspection and maintenance of the dipstick are necessary to ensure its effectiveness. A worn or damaged dipstick can lead to inaccurate readings, compromising the engine’s performance and safety. Engineers and mechanics should verify the condition of the dipstick during routine checks, ensuring it is free from debris and corrosion, and that it fits snugly within the oil reservoir.

Conclusion

The Cummins 3908314 Dipstick is a vital component in the maintenance and operation of Cummins engines. Its role in accurately measuring and monitoring oil levels ensures the engine operates efficiently and within optimal conditions. Regular maintenance and proper usage of this part are essential for the longevity and performance of commercial vehicles.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.