This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

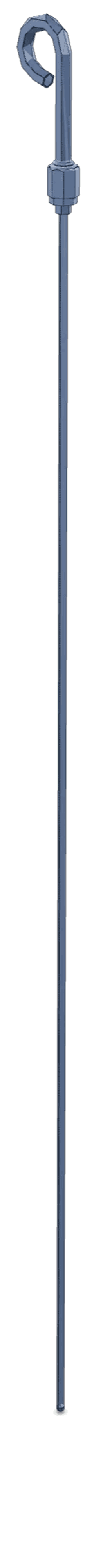

The Cummins 3915701 Dipstick is a specialized tool designed for use in heavy-duty trucks. Its primary function is to facilitate the measurement of oil levels within the engine, ensuring that the lubrication system operates efficiently. Proper maintenance of oil levels is vital for the longevity and performance of heavy-duty truck engines, making this Cummins part a significant component in routine vehicle maintenance.

Basic Concepts of a Dipstick

A dipstick is a thin, tapered metal or plastic rod used to measure the level of fluid in an engine. It is inserted into a tube that leads to the bottom of the oil reservoir. Once inserted and then removed, the dipstick provides a visual indication of the oil level through markings along its length. This simple yet effective tool plays a role in the lubrication system by allowing technicians to ensure that the engine has the appropriate amount of oil for optimal performance and protection against wear 1.

Purpose of the Cummins 3915701 Dipstick

The Cummins 3915701 Dipstick is specifically engineered to meet the demanding requirements of heavy-duty truck engines. It plays a role in the operation and maintenance of these vehicles by providing an accurate means to check oil levels. Ensuring the correct oil level is maintained helps in reducing engine wear, improving efficiency, and extending the lifespan of the engine. The dipstick’s design allows for easy access and accurate readings, which are crucial for the regular maintenance routines of heavy-duty trucks.

Key Features

The Cummins 3915701 Dipstick is characterized by several key features that enhance its functionality. It is constructed from high-quality materials to withstand the harsh conditions found in heavy-duty truck engines. The dipstick is designed with precise markings for accurate oil level readings. Additionally, its robust construction ensures durability and reliability over time, making it a dependable tool for professional use.

Benefits of Using the Cummins 3915701 Dipstick

Utilizing the Cummins 3915701 Dipstick offers several advantages. Its design ensures accuracy in oil level measurement, which is vital for maintaining engine health. The durability of the dipstick means it can withstand the rigors of heavy-duty truck environments, providing long-term reliability. Furthermore, its ease of use makes it a practical tool for both routine checks and maintenance procedures, contributing to efficient engine care.

Troubleshooting and Maintenance Suggestions

Common issues with dipsticks may include inaccurate readings or physical damage. To address these problems, it is important to ensure the dipstick is properly seated in its tube and that there are no obstructions affecting its movement. Regular cleaning of the dipstick can prevent buildup that may lead to inaccurate readings. Additionally, inspecting the dipstick for signs of wear or damage and replacing it as necessary will help maintain its effectiveness.

Installation and Usage Guidelines

To install and use the Cummins 3915701 Dipstick, follow these steps: First, ensure the vehicle is on a level surface and the engine is off. Locate the dipstick tube, usually found near the engine’s oil fill cap. Remove the dipstick by pulling it straight out, wipe it clean with a lint-free cloth, reinsert it fully, and then remove it again to check the oil level. Compare the oil level to the markings on the dipstick to determine if an oil change or top-up is necessary. Always follow safety precautions, such as wearing gloves and ensuring the engine is cool before checking the oil level.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the automotive industry, particularly in the production of diesel engines and related components. The company’s commitment to innovation, quality, and customer satisfaction has made it a trusted name in the field of engine technology 2.

Compatibility with Cummins Engines

The Cummins part 3915701, a Dipstick, is designed to be compatible with a range of Cummins engines, including the 6B5.9, QSB5.9 30, and CM550. This part is integral for maintaining the engine’s oil levels, ensuring optimal performance and longevity.

For the 6B5.9 engine, the dipstick is engineered to fit precisely into the designated oil level checking port, providing an accurate reading of the oil level. Similarly, in the QSB5.9 30 engine, the dipstick is crafted to align with the engine’s design, facilitating easy and reliable oil level checks.

The CM550 engine also benefits from the dipstick’s precise fit, ensuring that users can accurately monitor the oil levels without any complications. The design of the dipstick is such that it can be easily inserted and removed, providing a clear view of the oil level on the dipstick.

Across these engines, the dipstick’s compatibility is ensured by its standardized design, which adheres to Cummins’ specifications. This allows for a seamless integration with the engine’s oil system, providing a reliable method for oil level monitoring.

The dipstick’s material and construction are designed to withstand the engine’s operating conditions, ensuring durability and long-term use. This part is a critical component for maintaining the engine’s health, as it allows for timely oil level checks, preventing potential engine damage due to low oil levels.

Role of Part 3915701 Dipstick in Engine Systems

The part 3915701 dipstick is an essential component in the maintenance and monitoring of engine systems, specifically in relation to the oil level gauge.

Interaction with Oil Level Gauge

The dipstick works in conjunction with the oil level gauge to provide accurate readings of the engine’s oil level. When the dipstick is inserted into the engine’s oil filler neck and then withdrawn, the oil that adheres to it offers a visual and tactile means of assessing the oil level. This information is then cross-referenced with the markings on the dipstick, which correspond to the oil level gauge readings.

Ensuring Proper Oil Levels

Maintaining the correct oil level is vital for the engine’s lubrication system. The dipstick allows for regular checks, ensuring that the oil level remains within the optimal range. This, in turn, helps in preventing engine wear, reducing friction between moving parts, and enhancing overall engine performance and longevity.

Facilitating Oil Changes

During an oil change, the dipstick is used to verify that the new oil has been properly filled to the manufacturer’s specified level. This step is important for ensuring that the engine receives adequate lubrication from the outset, which is especially important after a complete oil drain.

Diagnostic Tool

The condition of the oil on the dipstick can also serve as a diagnostic tool. By examining the color and consistency of the oil, mechanics can gain insights into the engine’s health. For instance, dark or gritty oil may indicate the need for an oil change or further investigation into potential engine issues.

Integration with Engine Systems

In modern engine systems, the dipstick may also interact with automated oil level sensors. These sensors can provide real-time data to the vehicle’s onboard computer, allowing for more precise monitoring and alerting the driver to any anomalies in oil levels.

Conclusion

In summary, the Cummins 3915701 Dipstick plays a significant role in the maintenance and monitoring of engine systems by facilitating accurate oil level readings, ensuring proper lubrication, aiding in oil changes, and serving as a diagnostic tool. Its integration with other components like the oil level gauge enhances the overall efficiency and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.