This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3916850 Dipstick is a component designed for use in commercial trucks, specifically for monitoring engine oil levels. A dipstick serves as a tool for checking the quantity and condition of oil within an engine. This part is integral to the maintenance and operation of commercial trucks, ensuring that engines run efficiently and are protected from potential damage due to incorrect oil levels 1.

Basic Concepts of a Dipstick

A dipstick is a metal or plastic rod with a handle on one end, inserted into the oil reservoir of an engine. Its function is to provide a means of measuring the oil level and assessing the oil’s condition. When the dipstick is removed and wiped clean, reinserted, and then removed again, the oil level can be read from the markings on the dipstick. Monitoring fluid levels is vital for engine health, as it ensures that there is sufficient lubrication for moving parts, which reduces wear and tear 2. Dipsticks are commonly made from materials like stainless steel for durability and accuracy, or plastic for cost-effectiveness and resistance to certain chemicals.

Purpose of the Cummins 3916850 Dipstick

The Cummins 3916850 Dipstick plays a specific role in the operation and maintenance of commercial truck engines by allowing for precise measurement of engine oil levels. This ensures that the engine maintains optimal performance and longevity. By regularly checking the oil level with this dipstick, operators can prevent engine damage from oil starvation or overfilling, both of which can lead to severe engine issues 3.

Key Features

The Cummins 3916850 Dipstick is characterized by several key features. It is designed with a robust construction to withstand the harsh conditions of commercial truck engines. The dipstick is made from high-quality materials to ensure durability and accuracy in readings. It features clear markings for easy reading of oil levels and may include a temperature sensing bulb at the end to also gauge the oil temperature. These design elements contribute to its effectiveness in maintaining engine health 4.

Benefits

Using the Cummins 3916850 Dipstick offers several benefits. Its design ensures accuracy in fluid level measurement, which is crucial for maintaining engine efficiency. The durability of the materials used means it can withstand the rigors of commercial truck use, providing long-term reliability. Additionally, its ease of use facilitates quick and efficient oil level checks, contributing to overall engine health and operational efficiency.

Installation and Usage

Proper installation and usage of the Cummins 3916850 Dipstick are important for accurate readings and engine safety. Installation involves securing the dipstick tube into the engine’s oil reservoir and ensuring it is properly seated. To use, the dipstick should be fully inserted into the tube, then removed and wiped clean with a cloth. It is then reinserted and removed again to check the oil level against the markings on the dipstick. Correct installation and usage are vital for obtaining accurate oil level readings.

Troubleshooting and Maintenance

Common issues with dipsticks include inaccurate readings due to improper installation or damage to the dipstick. Troubleshooting may involve checking the installation, ensuring the dipstick is fully seated, or replacing a damaged dipstick. Maintenance tips for the Cummins 3916850 Dipstick include regular cleaning to remove oil buildup and periodic inspection for wear or damage. Regular checks and replacements, as needed, ensure the longevity and accuracy of the dipstick.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins plays a significant role in the commercial truck industry. The company’s commitment to quality and innovation is evident in its engine components, including the Cummins 3916850 Dipstick, which is designed to meet the demanding requirements of commercial truck engines.

Cummins Dipstick Part 3916850 Compatibility

The Cummins dipstick part number 3916850 is designed to be compatible with a range of Cummins engines, ensuring accurate and reliable oil level checks. This dipstick is specifically engineered to fit seamlessly with the following engines:

- 6B5.9

This dipstick is a crucial component for maintaining engine health, providing an essential tool for checking oil levels and ensuring the engine operates within optimal parameters. The design of part 3916850 ensures it fits snugly and functions effectively across the specified engine models.

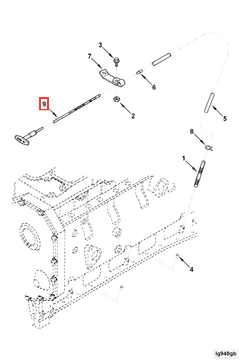

Role of Part 3916850 Dipstick in Engine Systems

The part 3916850 dipstick is an essential component in the engine systems, specifically designed to work in conjunction with the oil level gauge. Its primary function is to provide a precise measurement of the oil level within the engine.

When the dipstick is inserted into the engine’s oil filler tube, it comes into direct contact with the oil. Upon removal, the oil level can be read from the markings on the dipstick, which correspond to minimum and maximum oil levels. This information is then relayed to the oil level gauge, which may be a mechanical or digital display within the vehicle’s dashboard.

The accurate reading provided by the dipstick ensures that the oil level gauge displays the correct oil status to the operator. This, in turn, allows for timely oil changes and maintenance, preventing engine damage due to low oil levels or overfilling. The dipstick’s role is integral to maintaining the engine’s lubrication system, ensuring optimal performance and longevity of the engine components.

Conclusion

The Cummins 3916850 Dipstick is a vital component for the maintenance and operation of commercial truck engines. Its design ensures accurate measurement of engine oil levels, contributing to engine efficiency and longevity. Regular use and maintenance of this part are essential for preventing engine damage and ensuring optimal performance.

-

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Aird, F. (2001). Bosch Fuel Injection Systems. HP Books.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.