This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

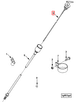

The Cummins 3931266 Dipstick is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the monitoring of oil levels within the engine, ensuring that the lubrication system operates within optimal parameters. This part is significant in the maintenance regimen of commercial trucks, as it allows for regular checks that can prevent engine wear and potential failures.

Basic Concepts of a Dipstick

A dipstick is a simple yet vital tool used in engines to measure the level of fluid, typically oil. It consists of a long, slender rod with a handle at one end, which is inserted into a tube connected to the oil reservoir. Once inserted and then withdrawn, the dipstick provides a visual indication of the oil level through markings along its length. This process plays a role in ensuring that the engine maintains adequate lubrication, which is fundamental for its efficient operation and longevity 1.

Purpose of the Cummins 3931266 Dipstick

The Cummins 3931266 Dipstick is specifically engineered to play a role in the operation and maintenance of commercial trucks by allowing for the precise checking of oil levels. This is particularly important in heavy-duty applications where engine lubrication is paramount to performance and durability. By providing an accurate reading of the oil level, this dipstick aids in the prevention of engine damage due to insufficient lubrication 2.

Key Features

The Cummins 3931266 Dipstick is characterized by its robust design and the use of high-quality materials, which contribute to its durability and reliability. It is crafted to withstand the harsh conditions typical of commercial truck environments. Unique attributes of this dipstick include its precise measurement markings and a design that ensures easy insertion and removal, facilitating straightforward and efficient oil level checks.

Benefits

Utilizing the Cummins 3931266 Dipstick offers several advantages. Its design ensures accuracy in fluid level measurement, which is crucial for maintaining engine health. The durability of the dipstick means it can endure the rigors of commercial truck use, reducing the need for frequent replacements. Additionally, its ease of use simplifies the maintenance process, allowing for quick and efficient oil level checks.

Installation and Usage

To install and use the Cummins 3931266 Dipstick, follow these steps: First, ensure the truck is on a level surface and the engine is off to obtain an accurate reading. Locate the dipstick tube, usually found near the engine’s oil fill cap. Pull the dipstick out completely, wipe it clean with a lint-free cloth, reinsert it fully, and then withdraw it again to check the oil level against the markings. This procedure should be performed regularly as part of the vehicle’s maintenance schedule.

Troubleshooting and Maintenance

Common issues with dipsticks may include difficulty in reading the oil level or the dipstick becoming stuck. To address these, ensure the dipstick is fully seated when checking the oil level and avoid forcing it if it seems stuck, as this could indicate a problem with the dipstick tube or the oil level being too low. Regular cleaning of the dipstick and inspecting it for wear or damage can help maintain its effectiveness and longevity.

Safety Considerations

When using the Cummins 3931266 Dipstick, it is important to observe certain safety practices. Always ensure the engine is off and has had time to cool before checking the oil level to avoid burns from hot engine components. Handle the dipstick carefully to prevent injury, and be mindful of the engine’s moving parts to avoid accidents. Following these precautions helps ensure a safe maintenance process.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s commitment to excellence is evident in its wide range of products, including the Cummins 3931266 Dipstick, which exemplifies Cummins’ dedication to providing high-quality components for the maintenance and operation of commercial vehicles 3.

Compatibility

The Cummins part 3931266, a Dipstick, is designed to be compatible with a range of Cummins engines. Specifically, it fits seamlessly with the 6C8.3, QSC8.3 CM554, and QSC8.3 CM850 (CM2850) engines. This compatibility ensures that the dipstick can be used across these engine models without modification, providing a standardized solution for oil level checks. The design of the dipstick is tailored to ensure it fits securely and functions effectively in these engines, facilitating easy and accurate oil level monitoring.

Role of Part 3931266 Dipstick in Engine Systems

The part 3931266 Dipstick is an essential component in the accurate measurement and monitoring of engine oil levels. It interfaces directly with the oil level gauge to provide real-time data on the oil status within the engine.

Interaction with Oil Level Gauge

The dipstick works in conjunction with the oil level gauge to offer a precise reading of the oil level. When the dipstick is inserted into the engine’s oil sump and then withdrawn, the oil adhering to it provides a visual and tactile indication of the oil level. This data is then interpreted by the oil level gauge, which translates the physical measurement into a readable format for the operator.

Ensuring Accurate Oil Level Readings

Accurate oil level readings are vital for the proper functioning and longevity of the engine. The dipstick’s design allows it to reach the oil sump, ensuring that the gauge receives consistent and reliable data. This, in turn, helps in maintaining optimal oil levels, which is fundamental for lubrication, cooling, and overall engine performance.

Integration with Engine Systems

In modern engine systems, the dipstick may also be part of an automated oil level monitoring system. Here, the dipstick’s data can be electronically transmitted to the engine’s control unit, allowing for automated alerts and maintenance scheduling. This integration enhances the engine’s reliability and reduces the likelihood of oil-related failures.

Maintenance and Inspection

Regular inspection and maintenance of the dipstick are necessary to ensure its effectiveness. Any contamination or damage to the dipstick can lead to inaccurate readings, potentially causing engine damage due to incorrect oil levels. Therefore, it is important to keep the dipstick clean and in good condition as part of routine engine maintenance.

Conclusion

The Cummins 3931266 Dipstick is a critical component for the maintenance and operation of commercial trucks. Its robust design, compatibility with various Cummins engines, and role in ensuring accurate oil level readings make it an indispensable tool for maintaining engine health and performance. Regular use and maintenance of this dipstick contribute to the longevity and efficiency of commercial truck engines.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.