This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

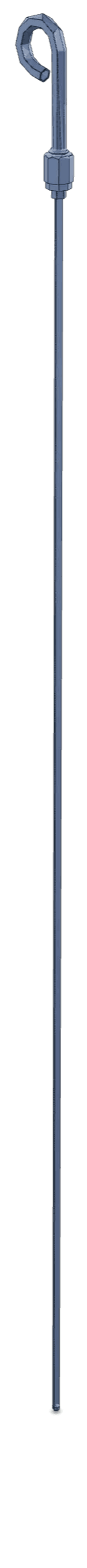

The Cummins 3933113 Dipstick is a component designed for use in heavy-duty trucks, specifically for monitoring oil levels within the engine. Its role in the maintenance routine of these vehicles is significant, as it allows for the accurate measurement of oil levels, which is vital for the proper functioning and longevity of the engine 1.

Basic Concepts of a Dipstick

A dipstick is a tool used in engines to measure the level of lubricant, typically oil. It consists of a long metal or plastic rod with graduated markings. When inserted into the engine’s oil sump and then withdrawn, the oil level can be read directly from the markings on the dipstick. This process allows for the assessment of whether the oil level is within the manufacturer’s recommended range, ensuring that the engine is adequately lubricated 2.

Purpose of the Cummins 3933113 Dipstick

The Cummins 3933113 Dipstick serves a specific function in the operation and maintenance of heavy-duty trucks. It is designed to measure the oil level within the engine, providing a straightforward method for technicians and operators to ensure that the engine has sufficient lubrication. Proper oil levels are necessary for reducing friction, cooling engine components, and carrying away contaminants, all of which contribute to the engine’s efficiency and durability 3.

Key Features

The Cummins 3933113 Dipstick is characterized by its robust design and the use of high-quality materials, which contribute to its durability and accuracy. It is crafted to withstand the harsh conditions typical of heavy-duty truck engines. The dipstick features clear, easy-to-read markings for precise oil level measurement and may include a handle for convenient use. Its design ensures that it fits securely within the engine, preventing oil leaks and ensuring accurate readings.

Benefits

Utilizing the Cummins 3933113 Dipstick offers several advantages. Its design allows for accurate measurement of oil levels, which is crucial for maintaining engine health. The durability of the dipstick ensures it can withstand the rigors of heavy-duty use, reducing the need for frequent replacements. Additionally, its ease of use simplifies the maintenance process, allowing for quick and efficient oil level checks.

Installation Process

Installing the Cummins 3933113 Dipstick involves a few straightforward steps. First, ensure the engine is turned off and has had sufficient time to cool. Locate the dipstick tube, typically found on the engine’s side. Remove the old dipstick by pulling it straight out of the tube. Insert the new Cummins 3933113 Dipstick into the tube until it reaches the bottom, then withdraw it to check the oil level. Ensure it is securely in place to prevent oil leaks.

Troubleshooting Common Issues

Common issues with dipsticks include inaccurate readings and physical damage. Inaccurate readings may result from a bent dipstick or incorrect installation. Ensuring the dipstick is straight and fully seated can resolve this. Physical damage, such as cracks or bends, may require replacement of the dipstick to maintain accurate oil level measurements and prevent oil leaks.

Maintenance Tips

To ensure the longevity and accurate functioning of the Cummins 3933113 Dipstick, regular maintenance is recommended. This includes checking the dipstick for signs of wear or damage during routine oil changes and ensuring it is clean and free from debris. Keeping the dipstick tube clear of obstructions will also contribute to accurate readings.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a key player in the automotive industry, particularly in the production of diesel engines and components for heavy-duty applications. The company’s commitment to innovation and quality has made its products, including the Cummins 3933113 Dipstick, trusted components in the maintenance and operation of heavy-duty trucks.

Compatibility with Cummins Engines

The dipstick part 3933113 is compatible with several Cummins engines, including but not limited to:

- 4B3.9: This engine model benefits from the precise measurements provided by the dipstick, ensuring that the oil level is maintained at the correct level to prevent engine damage.

Importance of the Dipstick

Regular checks using the dipstick are essential for engine maintenance. The dipstick allows mechanics and operators to verify the oil level, ensuring that the engine is neither overfilled nor underfilled. This simple yet crucial task helps in preventing engine wear and extending the lifespan of the engine.

Installation and Usage

Installing the dipstick part 3933113 is straightforward. It is designed to fit snugly into the designated oil level check port on the engine. When checking the oil level, the dipstick should be fully reinserted before pulling it out again to get an accurate reading. The markings on the dipstick indicate the acceptable oil level range, helping to ensure that the engine is properly lubricated.

Maintenance Tips

To maintain the functionality of the dipstick, it is important to handle it with care. Avoid dropping or bending the dipstick, as this can lead to inaccurate readings. Additionally, ensure that the oil level is checked when the engine is cold to get the most accurate measurement.

Role of Part 3933113 Dipstick in Engine Systems

The part 3933113 dipstick is an essential component in the maintenance and operation of engine systems, particularly in monitoring the oil level and ensuring the gauge provides accurate readings.

Oil Level Monitoring

The dipstick serves as a direct interface between the engine’s oil reservoir and the mechanic or operator. When inserted into the engine, it provides a physical measurement of the oil level. This is vital for maintaining the correct oil volume, which is necessary for lubricating moving parts, cooling the engine, and ensuring optimal performance. Regular checks with the dipstick help in identifying whether the oil level is within the safe operating range, thereby preventing potential engine damage due to low oil or overfilling.

Gauge Accuracy

The dipstick also plays a significant role in the accuracy of the oil level gauge. Many modern engines are equipped with an oil level sensor that interfaces with the dipstick. This sensor reads the oil level and transmits the data to the engine’s electronic control unit (ECU), which then displays the information on the dashboard gauge. The dipstick must be in good condition and properly installed to ensure that the sensor reads the oil level correctly. Any discrepancies in the dipstick’s condition or placement can lead to inaccurate gauge readings, potentially causing the operator to make incorrect decisions regarding oil top-ups or changes.

Integration with Engine Systems

In addition to its primary functions, the dipstick is integrated into the engine’s overall maintenance routine. It is often used in conjunction with the oil filter and the oil pan. During an oil change, the dipstick is removed to allow for the draining of old oil. Once the new oil is added, the dipstick is reinserted to check the level and ensure that the engine is ready for operation. This seamless integration highlights the dipstick’s importance in both routine maintenance and the day-to-day operation of the engine.

Conclusion

The Cummins 3933113 Dipstick is a vital component in the maintenance and operation of heavy-duty truck engines. Its accurate measurement of oil levels ensures proper lubrication, cooling, and contaminant removal, contributing to the engine’s efficiency and durability. Regular maintenance and proper installation of this Cummins part are essential for ensuring its longevity and accurate functioning.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.