This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

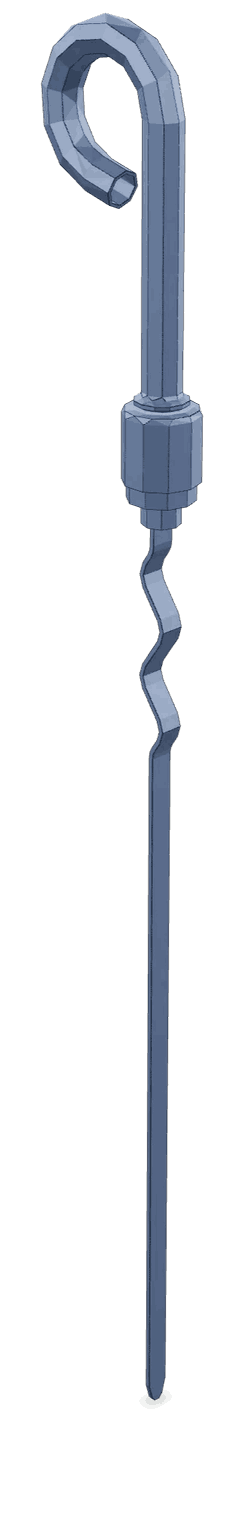

The Cummins 3933595 Dipstick is a specialized component designed for use in heavy-duty trucks. Its purpose is to facilitate the monitoring of engine oil levels, which is a fundamental aspect of vehicle maintenance. Ensuring the correct oil level is maintained contributes to the efficient operation and longevity of the engine 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet vital tool used in internal combustion engines to measure the level of lubricant, typically oil. It consists of a long, thin metal or plastic rod with a handle at one end. The rod is inserted into the engine’s oil sump through a tube. Once inserted and then withdrawn, the oil level can be read from the markings on the dipstick, which indicate the minimum and maximum acceptable oil levels 2.

Purpose of the Cummins 3933595 Dipstick

This Cummins part is specifically engineered to play a role in the operation and maintenance of heavy-duty trucks by allowing for the precise checking of oil levels. This is important for maintaining the lubrication system, which is crucial for reducing friction between moving parts, cooling the engine, and cleaning internal components 3.

Key Features

The Cummins 3933595 Dipstick is characterized by its robust design and the materials used in its construction, which are chosen for their durability and resistance to the high temperatures and pressures found within an engine. It features clear, easy-to-read markings for accurate oil level assessment and a secure fitting to prevent oil leaks.

Benefits

Using the Cummins 3933595 Dipstick offers several advantages. It provides accurate readings of oil levels, which is important for maintaining engine health. Its design ensures ease of use, allowing for quick and efficient checks. Additionally, by ensuring the engine is properly lubricated, the dipstick contributes to the longevity and performance of the engine.

Troubleshooting and Maintenance

Common issues with dipsticks may include inaccurate readings due to wear or damage, or oil leaks around the dipstick tube. Troubleshooting involves checking the condition of the dipstick and ensuring it is properly seated. Regular maintenance includes cleaning the dipstick before each use to remove any debris and checking for any signs of wear or damage that may affect its accuracy.

Installation and Usage

Proper installation of the Cummins 3933595 Dipstick involves ensuring it is correctly seated in the dipstick tube to prevent oil leaks. When checking the oil level, the engine should be turned off and allowed to settle for a few minutes to ensure an accurate reading. The dipstick should be wiped clean, reinserted fully, and then withdrawn to check the oil level against the markings.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industries. Their product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance engine performance and efficiency.

Cummins Dipstick Part 3933595 Compatibility

The Cummins dipstick part number 3933595 is designed to be compatible with several engine models, ensuring accurate oil level readings and maintenance. This dipstick is engineered to fit seamlessly into specific engine configurations, providing reliable performance and ease of use for technicians and operators alike.

Engine Compatibility

-

6C8.3 Engines

- The dipstick part 3933595 is specifically tailored for the 6C8.3 engine series. Its design ensures it fits perfectly into the engine’s oil pan, allowing for precise oil level checks. This compatibility is crucial for maintaining the engine’s optimal performance and longevity.

-

Grouped Engine Models

- The dipstick is also compatible with other engine models within the same series or similar configurations. This compatibility extends to engines that share similar oil pan designs and oil level checking requirements. Ensuring that the dipstick fits correctly is essential for accurate oil level monitoring and preventing potential engine damage due to incorrect oil levels.

Installation and Usage

-

Proper Installation

- When installing the dipstick part 3933595, it is important to follow the manufacturer’s guidelines to ensure a secure fit. This includes checking the oil pan for any obstructions or damage that might affect the dipstick’s ability to provide an accurate reading.

-

Routine Maintenance

- Regular use of the dipstick is recommended to monitor oil levels and ensure the engine operates within its specified parameters. This practice helps in early detection of oil leaks or other issues that might compromise engine performance.

Importance of Compatibility

-

Precision and Reliability

- The compatibility of the dipstick part 3933595 with specific engine models ensures that users can rely on accurate oil level readings. This precision is vital for maintaining engine health and preventing issues such as engine seizure or excessive wear.

-

Ease of Use

- Designed for ease of use, the dipstick allows for quick and straightforward oil level checks. This feature is particularly beneficial in environments where time-efficient maintenance is crucial, such as in heavy industrial or transportation settings.

Role of Part 3933595 Dipstick in Engine Systems

The part 3933595 dipstick is an essential component in the accurate measurement and monitoring of oil levels within an engine system. Its primary function is to provide a means for technicians to check the oil level without dismantling the engine.

When the dipstick is inserted into the oil filler tube, it comes into direct contact with the engine oil. Upon removal, the oil level can be observed on the dipstick, typically marked with minimum and maximum indicators. This simple yet effective mechanism allows for quick assessments of the oil level, ensuring it remains within the optimal range for engine performance and longevity.

In conjunction with the oil level gauge, the dipstick offers a visual and tactile method for oil level verification. The gauge, often located on the instrument panel, may be supplemented by the dipstick reading for more precise oil management. Regular checks using the dipstick help in identifying potential oil leaks, consumption rates, and the overall health of the lubrication system.

Maintaining the correct oil level is important for the lubrication of moving parts, cooling of the engine, and sealing of piston rings. The dipstick, therefore, plays a supportive role in the broader context of engine maintenance and operational efficiency.

Conclusion

The Cummins 3933595 Dipstick is a vital component for maintaining the health and efficiency of heavy-duty truck engines. Its accurate oil level readings, ease of use, and compatibility with specific engine models make it an indispensable tool for technicians and operators. Regular maintenance and proper use of this part ensure the longevity and optimal performance of the engine.

-

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

SAE International. Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International, 2013.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.