This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

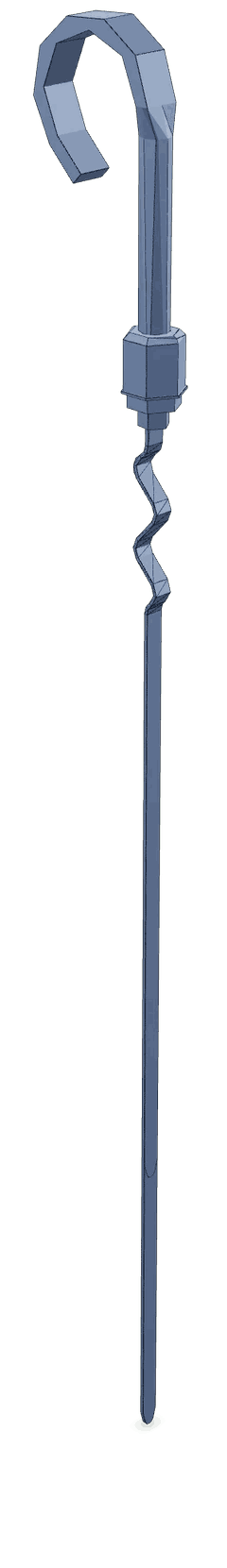

The Cummins 3937417 Dipstick is a specialized tool designed for use in commercial trucks equipped with Cummins engines. Its purpose is to facilitate the accurate measurement of engine oil levels, which is a fundamental aspect of maintaining and operating these vehicles. Proper oil levels are vital for engine performance and longevity, making the dipstick an integral component in routine maintenance checks 2.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in internal combustion engines to measure the level of engine oil. It consists of a long, slender metal or plastic rod with a handle at one end. The rod is inserted into the engine’s oil sump through a tube, and when withdrawn, the oil level can be read from markings on the dipstick. This measurement ensures that the engine has sufficient lubrication, which is necessary for reducing friction, cooling moving parts, and carrying away contaminants 3.

Purpose of the Cummins 3937417 Dipstick

The Cummins 3937417 Dipstick is specifically engineered to aid in the monitoring of engine oil levels in commercial trucks. By providing an accurate reading of the oil level, it allows for timely top-ups or changes, ensuring that the engine remains well-lubricated. This, in turn, contributes to the efficient operation of the engine and helps in preventing potential damage from insufficient lubrication 2.

Key Features

The Cummins 3937417 Dipstick is characterized by its robust design and high-quality materials, which enhance its durability and accuracy. It is crafted from corrosion-resistant materials to withstand the harsh environments often encountered by commercial trucks. The dipstick features clear, easy-to-read markings for precise oil level measurement and a secure fitting to prevent oil leaks 1.

Benefits of Using the Cummins 3937417 Dipstick

Utilizing the Cummins 3937417 Dipstick offers several advantages. Its design ensures accurate oil level readings, which are crucial for maintaining engine health. The durability of the dipstick means it can withstand frequent use without degradation. Additionally, its ease of use makes it a convenient tool for routine maintenance checks 2.

Installation Process

Installing the Cummins 3937417 Dipstick involves a few straightforward steps. First, ensure the engine is turned off and has cooled down. Locate the dipstick tube, remove the old dipstick, and insert the new Cummins 3937417 Dipstick into the tube until it reaches the bottom. Then, withdraw it slightly to get an accurate reading. Tools required are minimal, typically just a socket wrench for any necessary adjustments. Safety precautions include wearing protective gloves and ensuring the work area is clean and well-lit 2.

Usage Instructions

To use the Cummins 3937417 Dipstick, start by ensuring the truck is on a level surface and the engine is off. Remove the dipstick from the tube, wipe it clean with a lint-free cloth, reinsert it fully, and then withdraw it to check the oil level against the markings. For the most accurate reading, check the oil level when the engine is cold. Common mistakes to avoid include not wiping the dipstick clean before taking a reading and not ensuring the truck is on a level surface 3.

Troubleshooting Common Issues

Common issues with the Cummins 3937417 Dipstick may include inaccurate readings or physical damage. Inaccurate readings can often be resolved by ensuring the dipstick is fully inserted and wiped clean before each use. Physical damage, such as bends or cracks, may require replacement of the dipstick 2.

Maintenance Tips

To maintain the Cummins 3937417 Dipstick, regular cleaning after each use is recommended to remove any oil residue and prevent buildup. Inspect the dipstick periodically for signs of wear or damage. Keeping the dipstick tube clean and free of debris will also contribute to the accuracy of oil level readings 1.

Role in Preventive Maintenance

Incorporating the use of the Cummins 3937417 Dipstick into a preventive maintenance strategy is beneficial for commercial trucks. Regular oil level checks help in identifying potential issues before they lead to engine damage. This proactive approach can prolong the lifespan of the engine and enhance the overall performance and reliability of the vehicle 2.

Cummins Engine Dipstick Compatibility

The Cummins part 3937417, a Dipstick, is designed to fit into several of the company’s engine models. This dipstick is an essential component for checking the oil level in the engine, ensuring that the engine operates smoothly and efficiently. Here is a detailed look at the compatibility of this dipstick with various Cummins engines:

6C8.3

The 6C8.3 engine is one of the models that can utilize the Cummins part 3937417. This engine is known for its robust performance and reliability, making it a popular choice in various applications. The dipstick ensures that the oil level is maintained within the optimal range, preventing engine damage due to low oil levels 2.

ISC CM554

The ISC CM554 engine is another model that is compatible with the Cummins part 3937417. This engine is designed for heavy-duty applications, providing the power and durability needed for demanding tasks. The dipstick plays a crucial role in maintaining the engine’s oil level, ensuring consistent performance and longevity 2.

QSC8.3 CM554

The QSC8.3 CM554 engine is also compatible with the Cummins part 3937417. This engine is part of the QSC series, which is known for its versatility and efficiency. The dipstick is an integral part of the engine’s maintenance, helping to keep the oil level in check and ensuring that the engine runs smoothly 2.

QSC8.3 CM850 (CM2850)

The QSC8.3 CM850 (CM2850) engine is another model that can use the Cummins part 3937417. This engine is designed for high-performance applications, providing the power and reliability needed for various industrial and commercial uses. The dipstick ensures that the engine’s oil level is maintained, preventing issues related to low oil levels and ensuring optimal engine performance 2.

Role of Part 3937417 Dipstick in Engine Systems

The part 3937417 dipstick is an essential component in the maintenance and monitoring of engine systems. It interfaces directly with the oil level gauge system, facilitating accurate measurement and display of the engine’s oil level 3.

When the dipstick is inserted into the engine’s oil filler neck, it provides a physical means to check the oil level. The dipstick has marked levels that correspond to the minimum and maximum oil levels required for optimal engine performance.

Upon removal, the oil coating on the dipstick is visually inspected against these marks. This simple yet effective method allows mechanics and engineers to ensure that the engine has the appropriate amount of oil, which is vital for lubrication, cooling, and overall engine health 3.

Additionally, the dipstick plays a role in the oil level gauge system found in some vehicles. In these systems, the dipstick is equipped with a float or sensor that detects the oil level and transmits this information to the gauge on the dashboard. This real-time data allows for continuous monitoring of the oil level without the need for manual checks, enhancing convenience and safety 3.

Conclusion

The Cummins 3937417 Dipstick is a vital tool for maintaining and monitoring engine oil levels in commercial trucks. Its robust design, accurate readings, and ease of use make it an essential component in routine maintenance checks. By ensuring proper oil levels, this part contributes to the efficient operation and longevity of Cummins engines. Regular use and maintenance of the dipstick are recommended to prevent potential engine damage and ensure optimal performance.

-

Offroad Vehicle Dynamics Analysis Modelling and Optimization, Hamid Taghavifar and Aref Mardani, Springer, 2017

↩ ↩ -

Gasoline Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2015

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Introduction to Internal Combustion Engines, Fourth Edition, Richard Stone, Macmillan, 2012

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.