The Cummins 3944914 Dipstick is a component designed for use in commercial trucks, specifically for monitoring engine oil levels. Its role in the maintenance routine of these vehicles is significant, as it provides a straightforward method for operators to check the oil level, ensuring the engine operates within the manufacturer’s specified parameters.

Basic Concepts of a Dipstick

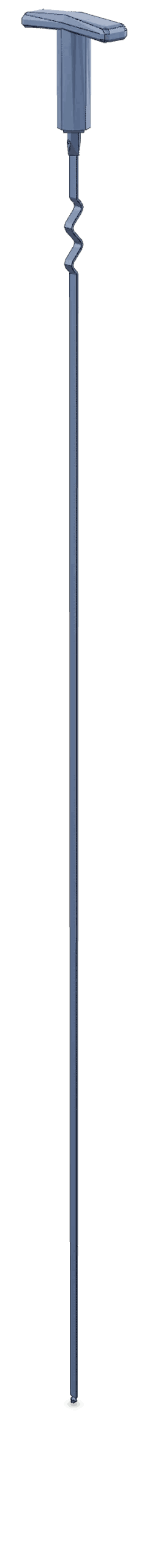

A dipstick is a simple yet vital tool used in engines to measure the level of fluid, typically oil, within the engine’s crankcase. It consists of a long, thin metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil sump. Markings along the length of the dipstick indicate the minimum and maximum oil levels. By withdrawing the dipstick and observing the oil level against these markings, one can determine if the oil level is within the acceptable range 1.

Purpose of the Cummins 3944914 Dipstick

The Cummins 3944914 Dipstick serves a specific function in the operation and maintenance of commercial trucks. It is utilized to check the oil levels within the engine, ensuring that there is sufficient lubrication for the moving parts. Proper oil levels are crucial for the engine’s efficiency, longevity, and overall performance. The dipstick allows for quick and easy checks, facilitating timely top-ups or changes as necessary.

Key Features

The Cummins 3944914 Dipstick is characterized by its robust design and the materials used in its construction. Typically made from high-quality steel, it is resistant to the high temperatures and pressures found within an engine environment. Its design includes clear markings for oil level indication, and it may feature a slightly curved tip to ensure accurate readings by conforming to the shape of the oil sump.

Benefits of Using the Cummins 3944914 Dipstick

Utilizing the Cummins 3944914 Dipstick offers several advantages. Its design ensures accurate readings, which is vital for maintaining the correct oil level in the engine. The ease of use, combined with its durability, makes it a reliable component for regular maintenance checks. Additionally, by ensuring the engine maintains the proper oil level, the dipstick contributes to the engine’s longevity and efficient operation.

Installation and Usage Guidelines

To install and use the Cummins 3944914 Dipstick correctly, follow these steps: First, ensure the vehicle is on a level surface and the engine is off to get an accurate reading. Locate the dipstick tube, usually found near the engine’s center. Pull the dipstick out completely, wipe it clean with a lint-free cloth, reinsert it fully, then pull it out again to check the oil level. The oil should be between the minimum and maximum marks. If necessary, add oil until it reaches the appropriate level.

Troubleshooting Common Issues

Common issues with dipsticks include inaccurate readings or physical damage. Inaccurate readings can often be resolved by ensuring the dipstick is fully seated in its tube and that the engine is on a level surface when checking the oil. Physical damage, such as bends or cracks, may require replacement of the dipstick to ensure accurate readings and prevent oil leaks.

Maintenance Tips

Regular maintenance of the Cummins 3944914 Dipstick involves cleaning it after each use to remove any oil residue that could affect the accuracy of future readings. Inspecting the dipstick for signs of wear or damage is also important. If the dipstick shows signs of significant wear, bending, or if the markings become illegible, it should be replaced to maintain the accuracy of oil level readings.

The Role of Cummins in the Automotive Industry

Cummins Inc. has a long-standing history in the automotive and heavy-duty truck industries, known for its commitment to quality and innovation. The company’s contributions include a wide range of components and systems designed to enhance the performance, efficiency, and reliability of vehicles. Cummins’ dedication to manufacturing high-quality parts, like the 3944914 Dipstick, underscores its role in supporting the automotive industry’s evolution and the needs of its customers.

Cummins Engine Dipstick Compatibility

The Cummins part number 3944914, which is a Dipstick, is designed to be compatible with several models of Cummins engines. This dipstick is an essential tool for checking the oil level in the engine, ensuring that the engine operates smoothly and efficiently.

ISB CM550

The ISB CM550 engine is a robust and reliable power unit, often utilized in various heavy-duty applications. The dipstick part 3944914 fits seamlessly into this engine, providing an accurate reading of the oil level. This compatibility ensures that users can maintain the engine’s performance by regularly checking and maintaining the oil levels.

QSB5.9 44 CM550

The QSB5.9 44 CM550 engine is another powerful and efficient engine model produced by Cummins. This engine is widely used in a variety of applications, from industrial machinery to agricultural equipment. The dipstick part 3944914 is specifically engineered to fit this engine model, allowing for easy and precise oil level checks. This ensures that the engine remains well-lubricated and operates at optimal efficiency.

Grouping of Engines

Both the ISB CM550 and QSB5.9 44 CM550 engines benefit from the use of the dipstick part 3944914. This compatibility is crucial for maintaining the health and longevity of these engines. By using the same dipstick for both models, users can streamline their maintenance processes, ensuring that they have the necessary tools to keep their engines running smoothly.

Role of Part 3944914 Dipstick in Engine Systems

The part 3944914 dipstick is an essential component in maintaining the operational integrity of engine systems by facilitating the measurement and monitoring of oil levels.

Interaction with the Oil Level

The primary function of the 3944914 dipstick is to provide a means for checking the oil level within the engine. When inserted into the oil filler tube and then withdrawn, the dipstick carries a film of oil that indicates the current oil level. This is vital for ensuring that the engine has sufficient lubrication, which is necessary for reducing friction between moving parts, cooling the engine, and cleaning internal components 2.

Connection to the Gauge

While the dipstick itself does not directly interface with a gauge, the information it provides is often used in conjunction with an oil level gauge or sensor in more advanced engine systems. In such setups, the dipstick serves as a manual verification tool, allowing engineers or mechanics to cross-reference the gauge readings with a physical measurement. This dual-check system enhances the reliability of oil level monitoring, ensuring that any discrepancies can be quickly identified and addressed.

Importance in Maintenance Routines

Regular use of the 3944914 dipstick in maintenance routines helps in preventing oil-related issues such as engine seizing due to low oil levels or reduced engine efficiency caused by overfilled oil levels. By providing a straightforward method to assess oil levels, the dipstick enables timely top-ups or drainage, maintaining optimal engine performance and longevity.

Conclusion

In summary, the 3944914 dipstick plays a significant role in the engine system by ensuring accurate oil level measurements, which are essential for the engine’s lubrication, cooling, and overall efficiency. Its compatibility with various Cummins engine models and its robust design make it a reliable tool for maintaining the health and performance of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.